The Complete Guide to MCU Production and Making: From Silicon to System

Introduction

In the invisible yet omnipresent world of modern technology, the Microcontroller Unit (MCU) stands as a fundamental pillar. These tiny, self-contained computing systems are the “brains” behind countless devices, from the simplest household appliance to the most complex industrial automation systems. The process of MCU production and making is a marvel of modern engineering, integrating advanced semiconductor fabrication, intricate circuit design, and sophisticated software development. As demand for smarter, more connected, and energy-efficient devices skyrockets across the Internet of Things (IoT), automotive, and consumer electronics sectors, understanding how these critical components are created is more important than ever. This guide delves deep into the multifaceted journey of an MCU, from its inception as a design concept to its final deployment in a finished product.

The Core Stages of MCU Production and Making

1. Design and Architecture: The Blueprint Phase

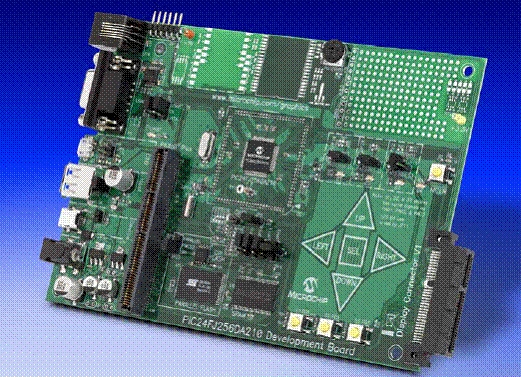

The journey of an MCU begins long before any physical silicon is touched. It starts with a detailed definition of requirements: processing power, memory size, power consumption, peripheral needs (like ADCs, communication interfaces), and target cost. Architects then select a suitable processor core, such as an ARM Cortex-M, RISC-V, or a proprietary architecture.

The heart of this phase is the creation of the Register Transfer Level (RTL) design using hardware description languages like VHDL or Verilog. This code defines the exact logic functions of the microcontroller. Following this, rigorous verification and simulation are conducted to ensure functional correctness. A critical subsequent step is physical design or layout, where the logical design is translated into geometric patterns for each layer of the silicon chip. This involves floorplanning, placement, clock tree synthesis, and routing—all optimized for performance, area, and power. Tools for Electronic Design Automation (EDA) are indispensable here. Finally, before mass production, a prototype run (tape-out) creates sample chips for real-world testing and validation.

2. Semiconductor Fabrication: The Silicon Crucible

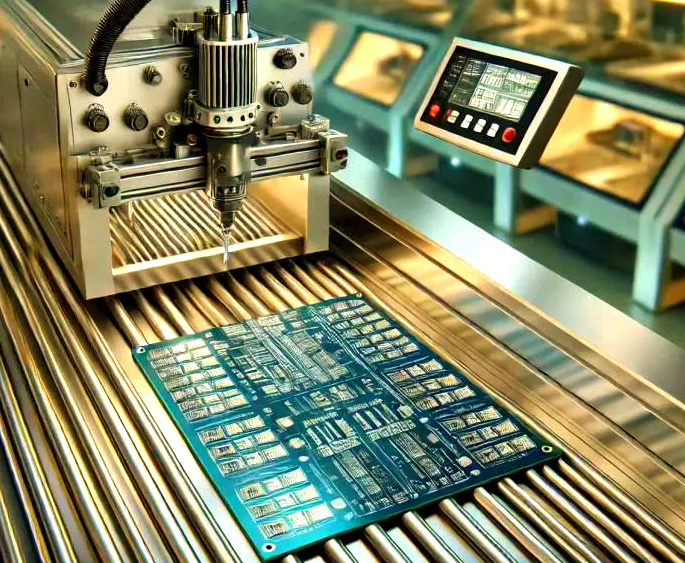

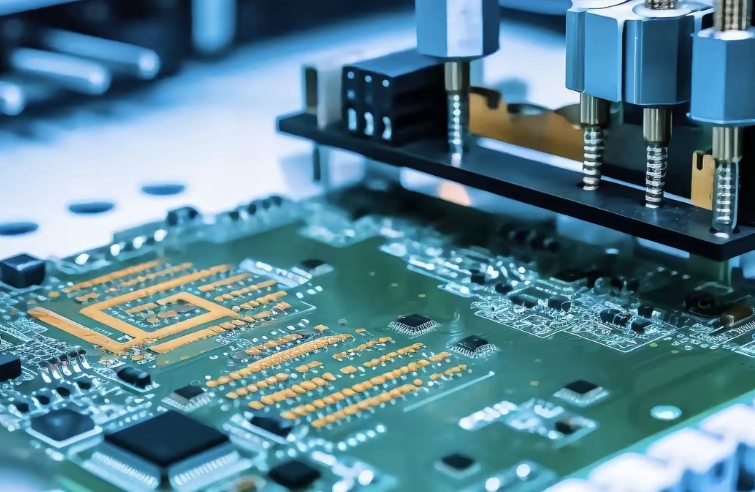

Once the design is finalized and verified, it moves to the foundry for fabrication. This is one of the most complex manufacturing processes on earth, occurring in ultra-clean environments known as fabs.

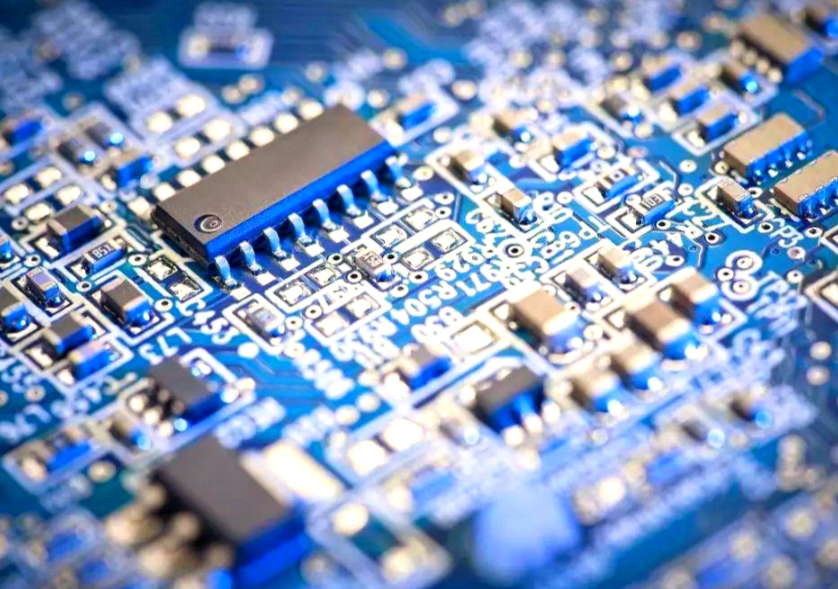

The process starts with a pure silicon wafer, which serves as the substrate. Through photolithography, the intricate circuit patterns from the design phase are projected onto the wafer using light and masks. A series of additive and subtractive steps follow: doping to modify silicon’s electrical properties, deposition to add material layers (like silicon dioxide or metal), and etching to remove unwanted material. This cycle is repeated dozens of times to build up the multi-layered structure of transistors and interconnects that form the MCU. Advanced nodes (e.g., 40nm, 28nm, or even smaller) allow for more transistors in a given area, directly impacting performance and power efficiency. After processing, each wafer contains hundreds or thousands of identical MCU dies.

3. Assembly, Testing, and Integration: Bringing It to Life

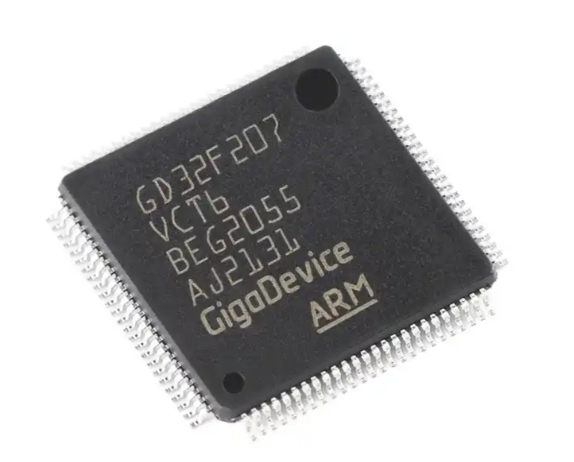

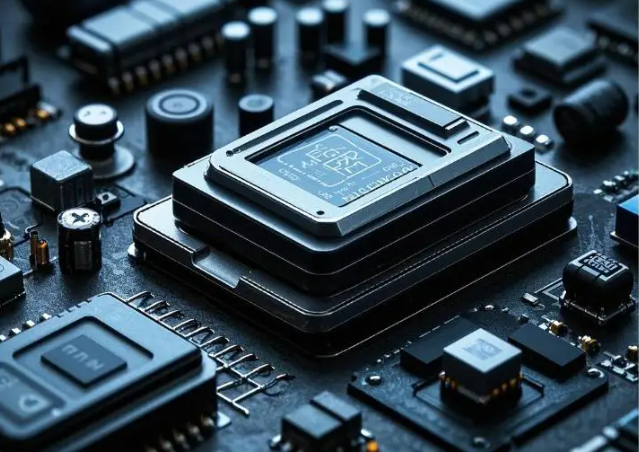

The fabricated wafers are then tested electrically using probe cards to identify functional dies. Non-functional dies are marked and discarded. The wafer is then diced into individual chips.

These bare dies undergo assembly or packaging, where they are placed into a protective casing that provides electrical connections (pins or balls), thermal management, and physical protection. Common packages include QFP, QFN, and BGA. Post-packaging, each MCU undergoes final rigorous testing under various voltages, temperatures, and frequencies to guarantee it meets all specifications for speed, power draw, and functionality.

However, the “making” of an MCU-based product doesn’t end with a packaged chip. It involves integrating this hardware with firmware—the low-level software that brings the MCU to life. Developers use toolchains (compilers, debuggers) and write code in C/C++ or similar languages to control peripherals and execute application logic. The ecosystem provided by the MCU manufacturer or third-party communities is crucial here. For professionals seeking reliable components and technical support for their projects across this entire chain—from sourcing to integration—platforms like ICGOODFIND can be instrumental. They streamline the connection between complex production pipelines and practical implementation needs.

Conclusion

The production and making of an MCU is a symphony of precision engineering spanning abstract design logic to atomic-scale material science and finally to tangible software control. It is a process defined by relentless innovation to make devices smaller, faster, cheaper, and more power-efficient. As we advance towards an increasingly automated and interconnected world driven by edge computing and AIoT (AI+IoT), the role of sophisticated yet cost-effective MCUs will only become more central. Understanding their creation not only highlights a cornerstone of technological progress but also empowers engineers and businesses to make informed decisions in selecting and utilizing these pivotal components for the next generation of smart devices.