PIC MCU Selection Manual: A Comprehensive Guide to Choosing the Right Microcontroller

Introduction

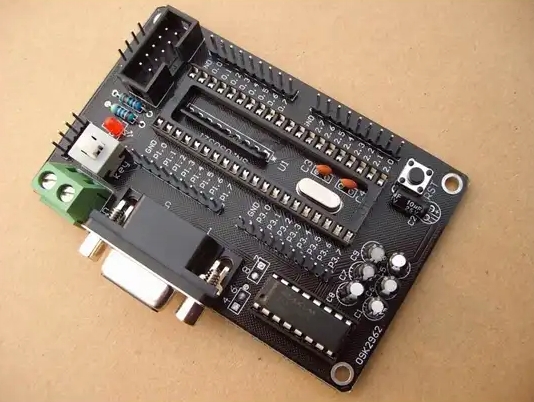

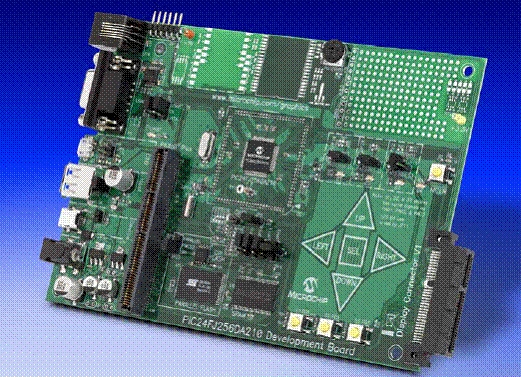

In the rapidly evolving world of embedded systems and electronics design, selecting the appropriate microcontroller (MCU) is one of the most critical decisions engineers face. Among the numerous options available, Microchip Technology’s PIC microcontroller family stands out as a popular choice for projects ranging from simple hobbyist creations to complex industrial applications. The PIC architecture has evolved significantly since its introduction, offering an extensive portfolio of devices with varying capabilities, peripherals, and price points. This diversity, while beneficial, can make the selection process daunting for both novice and experienced developers alike.

The importance of proper MCU selection cannot be overstated—it directly impacts project performance, power consumption, development time, manufacturing costs, and long-term maintainability. An ill-suited MCU can lead to compromised functionality, blown budgets, or even complete project failure. Conversely, a well-chosen microcontroller serves as the solid foundation upon which successful electronic products are built. This PIC MCU Selection Manual aims to demystify the selection process by providing a structured approach to evaluating your project requirements against the vast PIC microcontroller ecosystem.

Whether you’re designing battery-powered IoT devices, motor control systems, consumer electronics, or automotive applications, this guide will equip you with the knowledge needed to navigate Microchip’s extensive product catalog. We’ll explore key technical considerations, development ecosystem factors, and cost-related aspects that should inform your decision-making process. By following this manual, you’ll be better prepared to select a PIC MCU that not only meets your current project requirements but also accommodates future enhancements and scalability needs.

Part 1: Understanding Your Project Requirements

Before diving into the technical specifications of various PIC microcontrollers, it’s essential to have a clear understanding of your project requirements. This foundational step ensures that you select an MCU aligned with your application’s needs rather than choosing a device based solely on familiarity or marketing hype.

Performance requirements form the cornerstone of MCU selection. Begin by evaluating the computational demands of your application. Are you performing simple GPIO toggling or complex digital signal processing? Clock speed directly impacts how quickly your MCU can execute instructions, with PIC MCUs ranging from 32 kHz low-power devices to 200 MHz high-performance models. Equally important is the architecture—8-bit, 16-bit, or 32-bit—which affects how efficiently the processor handles different data types and mathematical operations. For applications requiring substantial number crunching or advanced algorithms, consider PIC32 MCUs with DSP capabilities or hardware floating-point units.

Memory considerations represent another critical aspect of MCU selection. Carefully estimate your program size to determine the required Flash memory, keeping in mind that code space requirements often grow during development. A good rule of thumb is to select a device with at least 20-30% more program memory than your initial estimate. Similarly, assess your RAM requirements for variables, stacks, and buffers—insufficient RAM can lead to mysterious crashes and debugging nightmares. For data storage needs, consider devices with integrated EEPROM or external memory interfaces if your application requires non-volatile data retention beyond program code.

Peripheral requirements should be mapped directly to your application’s functionality. Create a comprehensive list of necessary interfaces such as UART, I2C, SPI, USB, CAN, Ethernet, or specialized communication protocols. Identify analog needs including ADC resolution (8-bit to 16-bit), number of channels, sampling rate requirements, and whether you need digital-to-analog converters (DACs). For control applications, evaluate timer/counter needs—basic PWM generation, input capture for frequency measurement, or quadrature encoder interfaces for motor control. Don’t overlook future enhancements; selecting an MCU with additional peripherals provides flexibility for product upgrades without requiring a complete redesign.

Power constraints significantly influence MCU selection, especially for battery-powered or energy-harvesting applications. Determine whether your design requires ultra-low-power operation and identify which power modes (Active, Idle, Sleep, Deep Sleep) will be utilized during different operational states. Calculate battery life expectations and consider peripherals like low-power timers and real-time clock/calendar (RTCC) that can maintain functionality while the core processor sleeps. The latest PIC MCUs feature advanced power management techniques such as Peripheral Module Disable (PMD) that selectively turn off unused peripherals to minimize current consumption.

Part 2: Navigating the PIC Microcontroller Ecosystem

With a clear understanding of your project requirements, the next step involves navigating Microchip’s extensive PIC microcontroller ecosystem. The company offers hundreds of MCU variants across multiple architectures, each targeting specific application domains and performance points.

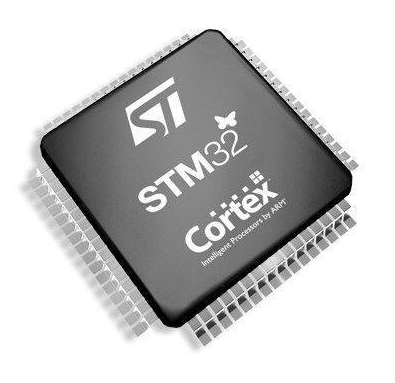

The PIC microcontroller families can be broadly categorized by their data bus width and core architecture. 8-bit PIC MCUs, including the baseline PIC10/12/16 families and enhanced mid-range PIC18 series, remain excellent choices for cost-sensitive applications requiring simple control functions. These devices feature deterministic operation, low latency interrupt response, and extensive peripheral integration while maintaining a small code footprint. The 16-bit PIC24 MCUs and dsPIC Digital Signal Controllers bridge the gap between 8-bit simplicity and 32-bit performance, offering enhanced computational capabilities while retaining excellent peripheral integration and real-time control features. At the top end, 32-bit PIC32 MCUs deliver high performance through MIPS processor cores running at speeds up to 200 MHz, making them suitable for applications requiring rich user interfaces, TCP/IP networking, or complex algorithms.

When comparing specific devices within these families, focus on peripheral integration as it directly impacts system cost and complexity. Modern PIC MCUs incorporate sophisticated peripherals that reduce external component count—look for features like direct memory access (DMA) controllers that offload data transfer tasks from the CPU, configurable logic cells (CLCs) that enable custom hardware functions without external components, and multiple independent PWM outputs with dead-band control for advanced motor applications. High-end devices may include cryptographic engines, graphics controllers, or analog front-ends tailored for specific markets such as medical or automotive.

The development ecosystem surrounding your chosen MCU significantly impacts project timeline and developer productivity. Evaluate available Integrated Development Environments (IDEs) like MPLAB X IDE and MPLAB Xpress, along with compiler options ranging from free versions to fully-optimized professional toolsets. Consider hardware debugging tools—Microchip offers programmers/debuggers like PICkit™ 4 and MPLAB ICD 4 with varying capabilities and price points. Perhaps most importantly, assess software support through libraries and code examples; the MPLAB Code Configurator (MCC) dramatically reduces development time by providing a graphical interface to configure peripherals and generate initialization code.

For developers seeking additional guidance in this complex landscape, specialized resources like ICGOODFIND offer curated component recommendations and technical insights that can streamline the selection process across various microcontroller platforms including the PIC ecosystem.

Package options and temperature ranges represent practical considerations that can’t be ignored. PIC MCUs are available in packages ranging from tiny 6-pin SOT-23 to high-pin-count TQFP and BGA packages—select one that matches your manufacturing capabilities and board space constraints. Consider environmental factors early; commercial (0°C to +70°C), industrial (-40°C to +85°C), and extended (-40°C to +125°C) temperature grades carry different price points and availability.

Part 3: Cost Optimization and Supply Chain Considerations

In commercial product development, technical excellence must be balanced against economic realities. A perfectly specified microcontroller that’s too expensive or unavailable jeopardizes product viability just as effectively as an underperforming device.

Total system cost analysis extends beyond the MCU’s sticker price to include all components required to make it functional. A seemingly inexpensive MCU might require external crystals, reset circuitry, voltage regulators, level translators, or additional memory chips that collectively exceed the cost of a more integrated solution. Carefully evaluate hardware integration opportunities—selecting a PIC MCU with integrated oscillators eliminates external crystal costs while built-in pull-up/pull-down resistors reduce discrete component count. Similarly, devices with wide operating voltage ranges (e.g., 1.8V to 5.5V) may eliminate need for voltage regulation entirely in battery-powered applications.

When evaluating pricing structures, understand that MCU costs vary significantly based on volume. Development quantities might carry premium pricing while production volumes can reduce unit costs substantially—always request volume pricing early in the selection process. Consider pin-compatible alternatives within the same family that offer varying memory sizes or peripheral sets; this strategy allows you to create product variants without board redesigns while maximizing purchasing leverage across multiple SKUs.

The long-term availability of your chosen MCU deserves careful consideration, particularly for products with extended lifecycles. Microchip’s product longevity program guarantees supply for many PIC devices for 10-15 years—verify whether your selected part qualifies for this program if you’re designing industrial, medical, or automotive products with multi-year production horizons. Beyond official policies,monitor industry trends that might affect future availability; devices built on older process technologies may face obsolescence pressures even if officially supported.

Supply chain resilience has become increasingly important in the post-pandemic electronics industry.Diversify your sourcing strategy by identifying alternative sources or functionally equivalent devices before committing to a specific PIC MCU.Lead time assessment should be part of your selection criteria—some popular PIC variants might have extended lead times while newer or niche devices could be more readily available.Consider second-source options where possible,**though compatibility verification is essential when exploring alternatives to ensure hardware and software compatibility.

Conclusion

Selecting the optimal PIC microcontroller requires methodical evaluation across multiple dimensions including technical specifications,development ecosystem support,and economic factors.By thoroughly understanding your project requirements,navigating Microchip’s extensive product portfolio with precision,and considering total system cost alongside supply chain resilience,you can identify the ideal MCU that balances performance,features,and budget.

The structured approach outlined in this PIC MCU Selection Manual provides a framework for making informed decisions rather than relying on guesswork or past preferences.Remember that microcontroller selection isn’t about finding the most powerful device available,but rather identifying the device that most closely matches your application’s specific needs while providing appropriate headroom for future enhancements.

As you embark on your next embedded project,leverage available resources including Microchip’s parametric search tools,online communities,application notes,and specialized platforms like ICGOODFIND that aggregate technical insights across components.**These resources complement your technical analysis and help validate selection decisions before committing to hardware design.

Ultimately,successful MCU selection merges engineering rigor with practical business considerations.By applying the principles detailed in this manual,you’ll be well-equipped to navigate the complex landscape of PIC microcontrollers and select devices that form the solid foundation for successful,profitable electronic products in today’s competitive marketplace.