The Ultimate Guide to MCU Selection: Powering Your Embedded Design Success

Introduction

In the intricate world of embedded systems, the choice of the Microcontroller Unit (MCU) stands as one of the most critical and defining decisions an engineer or project manager can make. This single component acts as the brain of countless devices, from smart home gadgets and wearable technology to industrial automation and automotive control systems. The process of MCU selection is far more nuanced than simply comparing clock speeds or pin counts; it is a multidimensional balancing act that directly impacts a product’s performance, power efficiency, cost, time-to-market, and long-term viability. A hasty or ill-informed selection can lead to project delays, blown budgets, and products that fail to meet market expectations. Conversely, a strategic and thorough selection process lays a robust foundation for innovation and reliability. In today’s rapidly evolving landscape, leveraging comprehensive resources like ICGOODFIND can be the key differentiator, providing access to critical data sheets, comparison tools, and supplier information to navigate the vast MCU ecosystem efficiently.

Main Body

Part 1: Core Technical Parameters and Project Requirements Alignment

The first phase of MCU selection involves a deep introspection of your project’s technical needs and mapping them onto the MCU’s core specifications. This is where engineering requirements meet silicon reality.

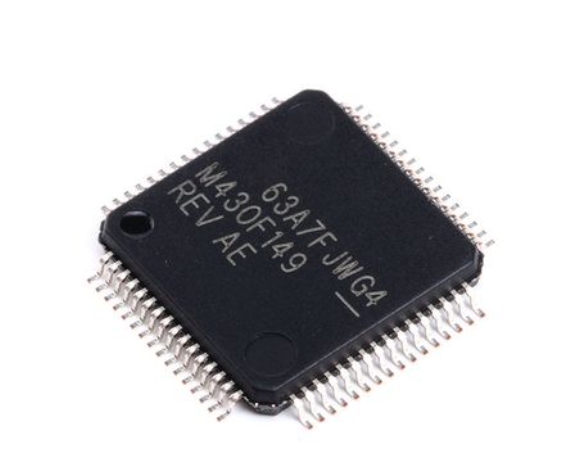

- Processing Core and Architecture: The heart of the MCU defines its fundamental capabilities. Choices range from simple 8-bit cores (e.g., AVR, 8051) for basic control tasks, to powerful 32-bit ARM Cortex-M cores (M0, M3, M4, M7, M33) which dominate complex applications. Considerations include whether you need a DSP (Digital Signal Processing) extension for mathematical computations, an FPU (Floating-Point Unit) for high-speed floating-point math, or a memory management unit for advanced operating systems.

- Memory Configuration: Flash memory for code storage and SRAM for runtime data are paramount. Always allocate a significant margin (typically 20-30%) above your initial code size estimate for future features and updates. The availability of external memory interfaces (like Quad-SPI for external flash) can offer valuable scalability.

- Power Consumption Profile: This is non-negotiable for battery-powered devices. You must analyze the MCU’s power modes—active, sleep, deep sleep, and shutdown—and their corresponding current draws. The ability to wake quickly from a low-power state and process data efficiently (high performance per watt) is often more important than raw peak speed.

- Peripheral Set: The required peripherals are dictated by your application’s interface needs. This includes communication protocols (UART, I2C, SPI, USB, CAN, Ethernet), analog components (ADC resolution and sampling rate, DAC, comparators), timers for PWM generation, and hardware security modules. Selecting an MCU with peripherals that match your needs without requiring external chips reduces system complexity and cost.

Part 2: The Ecosystem and Lifecycle Considerations

An MCU is not an island. Its surrounding ecosystem and long-term availability are crucial for development efficiency and product sustainability.

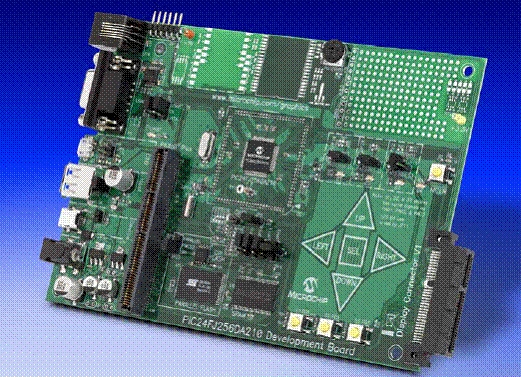

- Development Tools and Software Support: The quality of the Integrated Development Environment (IDE), compiler efficiency, debugger/programmer hardware, and software libraries can drastically affect development time. A strong ecosystem offers robust middleware (RTOS, communication stacks, file systems), driver libraries, and code generation tools. Vendor-provided evaluation kits are invaluable for early prototyping.

- Community and Vendor Support: A large, active user community and responsive vendor application support are invaluable resources for troubleshooting and learning. Forums, application notes, reference designs, and timely technical support can help overcome challenging development hurdles.

- Total Cost Analysis: Look beyond the unit price of the MCU chip itself. Calculate the Total Cost of Ownership (TCO), which includes required external components (e.g., crystal oscillators, voltage regulators), development tool costs, programming time in manufacturing, and potential royalty fees for middleware.

- Supply Chain Reliability and Longevity: In the post-pandemic era, this factor has moved to the forefront. Ensure the MCU is not on a perpetual allocation list or nearing end-of-life. For industrial or automotive products with long lifecycles, choosing a manufacturer known for long-term product support and stable supply is essential to avoid costly redesigns mid-production.

Part 3: Advanced Factors and Future-Proofing

For cutting-edge or scalable products, several advanced considerations come into play.

- Hardware Security Features: With rising cyber-physical threats, security must be designed in from the start. Look for MCUs with dedicated hardware security features like secure boot, cryptographic accelerators (AES, SHA, ECC), true random number generators (TRNG), tamper detection pins, and secure storage areas. These provide a hardware root of trust that software alone cannot achieve.

- Connectivity Integration: For IoT devices, having integrated wireless connectivity (e.g., Bluetooth Low Energy (BLE), Wi-Fi, LoRa, or cellular modems) within the MCU package can simplify RF design, reduce footprint, and often lower overall power consumption compared to discrete “MCU + radio chip” solutions.

- Scalability Within a Family: Successful products often spawn variants. Choosing an MCU from a broad family that offers pin-compatible devices with more/less memory, performance, or peripherals allows for creating product tiers without redesigning the core PCB layout.

- Artificial Intelligence at the Edge: Emerging applications require local inference on ML models. Some modern MCUs now include micro NPUs (Neural Processing Units) or instructions optimized for running lightweight AI models efficiently at ultra-low power—a key differentiator for smart sensors and predictive maintenance devices.

Navigating this complex matrix of technical specs, vendor landscapes, and market availability is where a platform like ICGOODFIND proves indispensable. It aggregates critical information from countless suppliers into a searchable database, allowing engineers to quickly filter MCUs by parameters (core type, peripheral mix, power specs), compare side-by-side, and access direct links to datasheets and distributors. This dramatically accelerates the initial research phase of MCU selection, ensuring no viable option is overlooked.

Conclusion

The journey of MCU selection is a foundational engineering discipline that blends detailed technical analysis with strategic business foresight. It requires moving beyond basic datasheet comparisons to evaluate the complete picture: from core performance metrics and power envelopes to the vitality of the development ecosystem and the stability of the supply chain. By methodically aligning project requirements with technical specifications, prioritizing ecosystem strength for development agility, and factoring in advanced needs like security and connectivity, teams can make a choice that ensures not just a functional prototype but a successful, scalable, and sustainable product in the market. In this data-driven decision-making process, utilizing comprehensive component search engines like ICGOODFIND is no longer just an advantage—it is an essential practice for efficient and informed component selection in a crowded global marketplace.