MCU vs. PLC: Choosing the Right Controller for Your Automation Needs

Introduction

In the rapidly evolving landscape of industrial automation and embedded systems, two pivotal technologies stand at the forefront: the Microcontroller Unit (MCU) and the Programmable Logic Controller (PLC). While both serve as the “brains” of electronic control systems, their design philosophies, applications, and operational paradigms differ significantly. For engineers, system integrators, and decision-makers, selecting the appropriate controller is not merely a technical choice but a strategic business decision impacting cost, reliability, scalability, and long-term maintenance. This article delves deep into the core distinctions, optimal use cases, and key selection criteria between MCUs and PLCs. Understanding this dichotomy is essential for designing efficient, robust, and future-proof systems. For professionals seeking to navigate this complex landscape with expert insights and curated component solutions, platforms like ICGOODFIND offer invaluable resources to identify the perfect components for your specific project requirements.

Main Body

Part 1: Fundamental Architectures and Design Philosophies

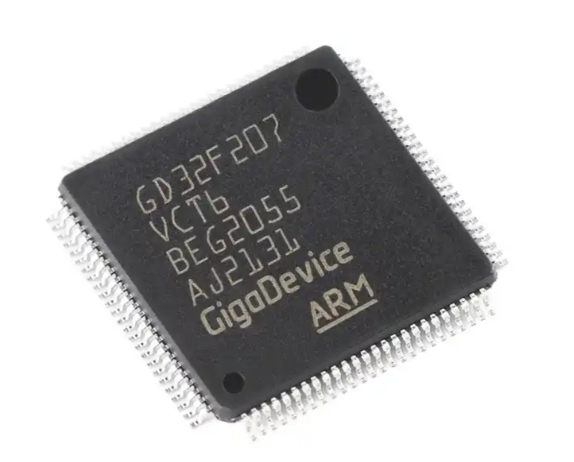

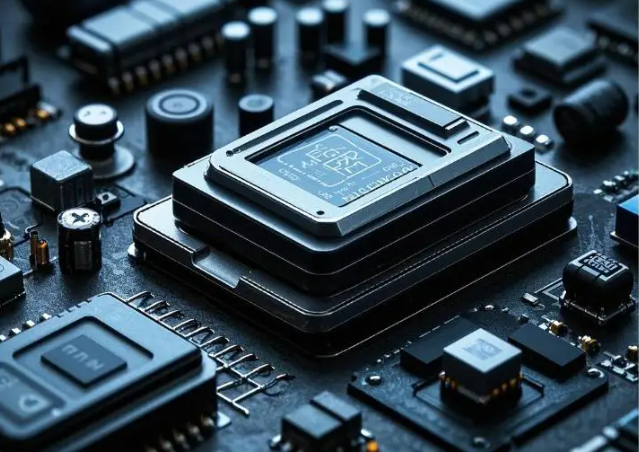

At their core, MCUs and PLCs are built for different environments and expectations. A Microcontroller Unit (MCU) is a compact integrated circuit designed to govern a specific operation in an embedded system. It is essentially a single-chip computer containing a processor core, memory (both RAM and ROM/Flash), and programmable input/output peripherals. MCUs are designed for high-volume, cost-sensitive applications where the control logic is fixed and deeply integrated into the product. Think of them as the dedicated controllers inside your washing machine, car engine control unit, or a smart sensor. Their programming is typically done in low-level languages like C or C++, requiring deep hardware knowledge. The development cycle involves designing the hardware PCB around the MCU and writing firmware that interacts directly with registers and physical pins.

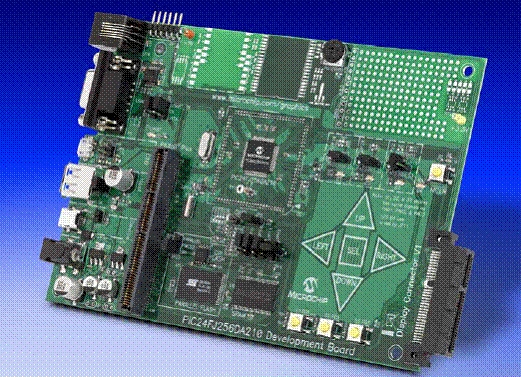

In stark contrast, a Programmable Logic Controller (PLC) is an industrially hardened computer designed for real-time control of manufacturing processes or machinery. Its architecture is modular and robust. A standard PLC consists of a central processing unit (CPU), a power supply, input/output (I/O) modules, and often a communication module. This modularity allows for easy customization and expansion in the field. The most defining characteristic of a PLC is its software environment, which uses standardized programming languages defined by the IEC 61131-3 standard, such as Ladder Logic (LAD), Function Block Diagram (FBD), or Structured Text (ST). These languages, particularly Ladder Logic which resembles relay logic diagrams, were created to be understandable by electricians and plant engineers, not just software programmers. Furthermore, PLCs are built to survive in harsh industrial environments with extreme temperatures, vibration, electrical noise, and humidity—a level of ruggedness most standard MCU-based boards do not possess natively.

Part 2: Comparative Analysis: Strengths and Weaknesses

Choosing between an MCU and a PLC involves weighing their inherent advantages against project constraints.

MCU Advantages: * Cost & Size: For mass-produced goods, MCUs offer an unbeatable low unit cost and minimal footprint. * Customization & Optimization: Designers have complete control over hardware and firmware, allowing for highly optimized performance for a single task, minimizing power consumption and maximizing speed. * Integration: They enable fully integrated products where the controller is invisible to the end-user.

MCU Disadvantages: * Development Complexity: Requires expertise in electronics and embedded programming. The development cycle is longer. * Environmental Ruggedness: Not inherently hardened for industrial settings; additional design effort is needed for protection. * Maintenance & Updates: Firmware updates can be challenging in deployed systems, and troubleshooting requires specialized tools.

PLC Advantages: * Robustness & Reliability: Designed from the ground up for 24⁄7 industrial operation with high mean time between failures (MTBF). * Ease of Programming & Maintenance: Standardized languages lower the engineering barrier. Programs can be modified on-the-fly, and modules can be hot-swapped often without shutting down the entire line. * Modularity & Scalability: I/O counts can be easily expanded by adding modules. This offers tremendous flexibility for system upgrades. * Safety & Standards: PLCs often come with certifications and are integral to building systems compliant with industrial safety standards (e.g., SIL, PL).

PLC Disadvantages: * Cost: The per-unit cost is significantly higher than a bare MCU chip. * Size & Overhead: The hardware is larger, and the software runtime adds latency overhead compared to lean MCU firmware. * Less Customization: You are confined to the manufacturer’s hardware ecosystem and supported I/O types.

Part 3: Application Scenarios and Selection Guidelines

The choice becomes clear when mapped against typical application domains.

Where MCUs Reign Supreme: MCUs are the undisputed choice for embedded consumer electronics, IoT devices, automotive subsystems (like infotainment or window control), medical devices, and high-volume engineered products. If you are building a product where the controller is a component of a larger whole, where form factor and unit cost are critical, and where the operating environment is controlled, an MCU-based design is appropriate.

Where PLCs Are Indispensable: PLCs are the backbone of factory automation assembly lines, robotic work cells, food & beverage processing plants, water treatment facilities, and energy management systems (SCADA). Any application involving the control of heavy machinery, multiple coordinated processes in real-time, or operation in environments with dirt, moisture, or electrical interference is squarely in PLC territory. Their deterministic response and fail-safe operation are non-negotiable here.

Key Selection Criteria: 1. Environment: Is it a clean office or a dusty, vibrating factory floor? 2. Scale & Lifecycle: Are you building 10 machines or 10 million devices? Will the system need to be modified frequently over a 15-year lifespan? 3. Expertise: Do you have embedded C programmers or industrial automation engineers? 4. Real-Time Needs: Does the process require deterministic, millisecond-level response guarantees? 5. Budget: Consider total cost of ownership—not just component cost but development time, maintenance ease, and downtime costs.

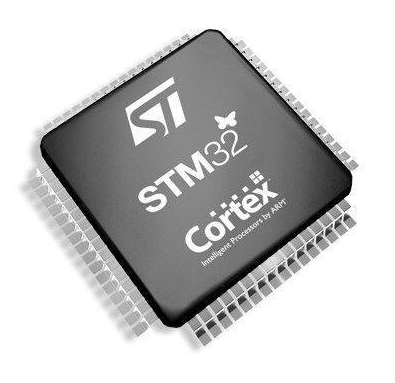

For engineers tasked with sourcing components for either path—from specific ARM Cortex-M series MCUs to industrial-grade PLC modules—navigating global suppliers can be daunting. This is where leveraging a specialized platform becomes crucial. A resource like ICGOODFIND can streamline this process by providing access to a vast inventory of verified components from multiple suppliers, enabling efficient comparison and procurement for both prototyping and production phases.

Conclusion

The debate between MCU and PLC is not about which technology is superior, but about which tool is right for the job. MCUs offer unparalleled customization and cost-efficiency for embedded products destined for controlled environments and high-volume production. PLCs deliver unmatched robustness, ease of use, and reliability for industrial automation where downtime is catastrophic. The modern automation landscape increasingly sees hybrid approaches—for instance, using MCUs within smart sensors or edge devices that communicate with a central PLC via industrial networks. Ultimately, a clear understanding of your project’s core requirements—environmental conditions, scale, performance needs, and team skills—will illuminate the correct path forward. As technology converges, making informed decisions supported by reliable component sourcing platforms like ICGOODFIND will remain key to building successful and sustainable control systems.