MCU Sensor Tutorial: A Comprehensive Guide to Connecting, Programming, and Optimizing Sensors with Microcontrollers

Introduction

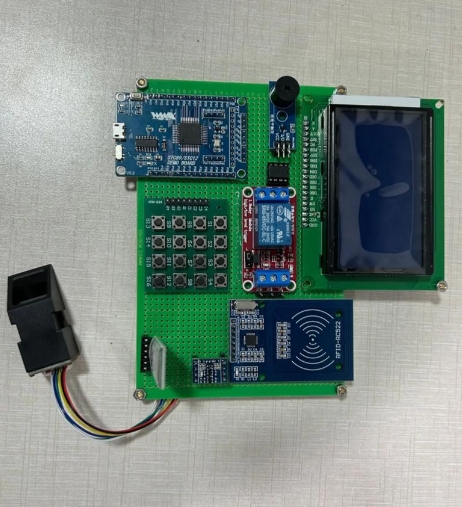

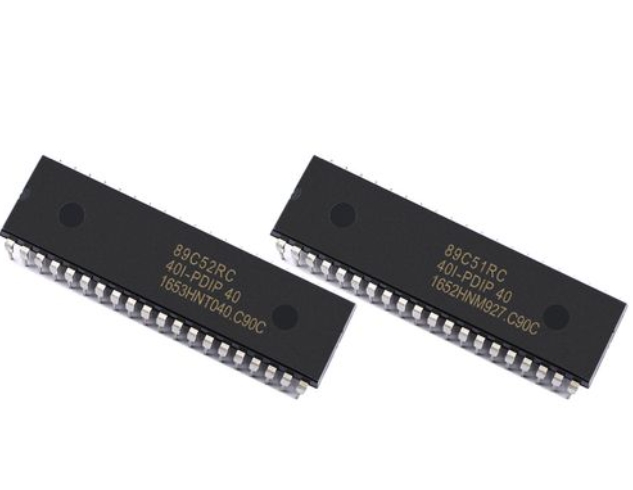

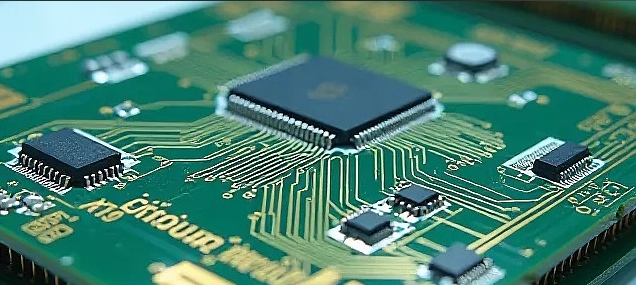

In the rapidly evolving world of embedded systems and the Internet of Things (IoT), the ability to effectively integrate sensors with Microcontroller Units (MCUs) is a foundational skill. An MCU sensor tutorial serves as a critical roadmap for engineers, hobbyists, and students aiming to bridge the physical and digital worlds. Sensors act as the sensory organs of any smart device, measuring parameters like temperature, pressure, motion, and light. However, the raw data they produce is meaningless without a brain to process it—the MCU. This guide delves deep into the practical aspects of selecting, interfacing, programming, and troubleshooting sensors with popular microcontroller platforms. Whether you’re building a weather station, a smart home device, or an industrial monitor, mastering this synergy is key. For those seeking specialized components or in-depth project resources, platforms like ICGOODFIND can be an invaluable tool in sourcing the right sensors and MCUs for your specific application needs.

Part 1: Fundamentals of MCU and Sensor Interfacing

The first step in any sensor project is understanding the communication bridge between the sensor and the MCU. Not all sensors speak the same “language,” so choosing the correct protocol is paramount.

Digital vs. Analog Sensors: The type of signal a sensor outputs dictates how you connect it. Analog sensors, such as many temperature probes or light-dependent resistors (LDRs), output a continuous voltage signal proportional to the measured phenomenon. This signal must be connected to an MCU’s Analog-to-Digital Converter (ADC) pin. The resolution of the ADC (e.g., 10-bit, 12-bit) determines how finely this analog world can be translated into digital values. Digital sensors, on the other hand, output discrete binary data. They often have built-in signal conditioning and conversion, providing more noise-resistant and readily usable data through standard communication protocols.

Essential Communication Protocols: Three protocols form the backbone of most MCU-sensor communications. * I2C (Inter-Integrated Circuit): A two-wire protocol (Serial Data Line SDA and Serial Clock Line SCL) perfect for connecting multiple slave devices (sensors) to one or more master devices (MCUs). Each sensor on the I2C bus must have a unique address, which is crucial for conflict-free communication. * SPI (Serial Peripheral Interface): A faster, full-duplex protocol using four wires (MISO, MOSI, SCK, and CS/SS). It’s excellent for high-speed data transfer over short distances. Unlike I2C, SPI uses a dedicated Chip Select (CS) line for each slave device, simplifying addressing but requiring more MCU pins. * UART (Universal Asynchronous Receiver/Transmitter): A simple two-wire (TX, RX) protocol for asynchronous serial communication. Many sensors, like certain GPS modules or humidity sensors, output data serially. It’s straightforward but typically used for one-to-one connections.

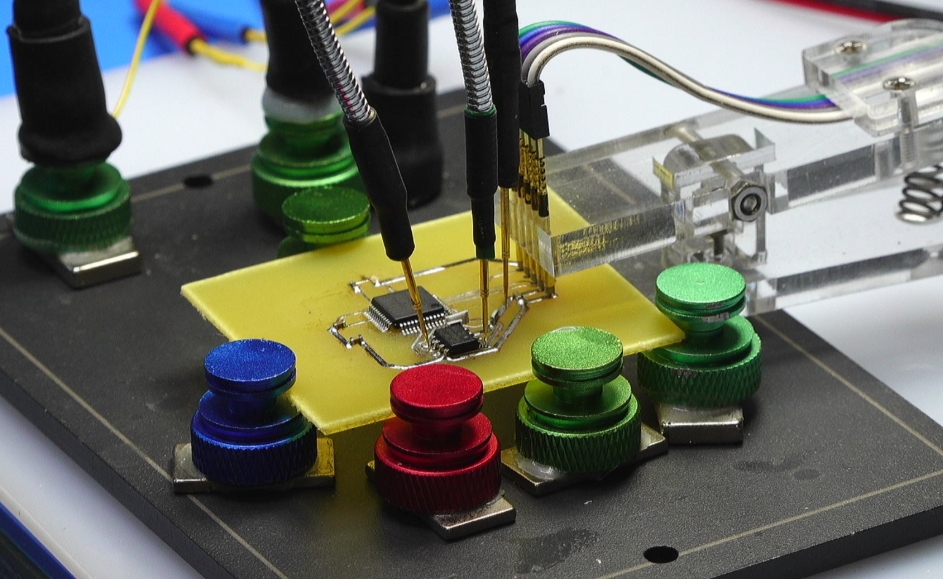

Power and Timing Considerations: Providing clean, stable power to your sensor is non-negotiable. Noise on the power line can directly corrupt measurements. Always use decoupling capacitors (typically 0.1µF ceramic) close to the sensor’s power pins. Furthermore, many sensors require specific timing sequences for initialization or triggering measurements—meticulously following the datasheet’s timing diagrams is essential for reliable operation.

Part 2: Step-by-Step Programming and Data Processing

With hardware connected, the next phase is writing firmware to read and interpret sensor data. This process involves library integration, raw data acquisition, and meaningful conversion.

Leveraging Libraries and Datasheets: Start by checking if there is an existing library for your specific sensor and MCU platform (e.g., Arduino, STM32Cube, ESP-IDF). A well-written library abstracts the low-level protocol commands, allowing you to focus on functionality. However, blindly relying on libraries without understanding the underlying principles is risky. The sensor’s datasheet is your ultimate guide; it contains the register maps, command codes, timing requirements, and mathematical formulas for converting raw readings into real-world units.

Reading and Converting Sensor Data: The process typically follows this pattern: 1. Initialization: Configure the MCU’s communication peripherals (I2C, SPI, ADC) and the sensor itself (e.g., set measurement range, output data rate). 2. Data Acquisition: Send a read command or trigger a measurement, then read the raw bytes or ADC values from the sensor. 3. Data Conversion: Apply the formula from the datasheet. For example, a 12-bit ADC reading might need scaling: Voltage = (ADC_Reading / 4095) * Reference_Voltage. Then, a sensor-specific transfer function converts voltage to temperature or pressure. 4. Calibration: No sensor is perfectly accurate out of the box. Offset and gain errors are common. Simple two-point calibration—taking readings at known reference points—can dramatically improve accuracy. Store calibration coefficients in non-volatile memory.

Error Handling and Filtering: Real-world data is noisy. Implement basic software filters like a moving average or a median filter to smooth readings. Furthermore, robust code must handle communication errors. Always check function return values from libraries and consider implementing timeouts or checksums to verify data integrity.

Part 3: Advanced Integration and Optimization Techniques

Moving beyond basic connectivity opens doors to creating sophisticated, reliable systems.

Sensor Fusion: This powerful technique involves combining data from multiple different sensors to produce information that is more accurate and reliable than what could be derived from a single source. A classic example is using an Inertial Measurement Unit (IMU) containing an accelerometer and gyroscope. By fusing their data with an algorithm like a Complementary or Kalman filter, you can derive stable orientation estimates that compensate for each sensor’s drift and noise.

Low-Power Design Strategies: For battery-operated IoT devices, power management is critical. * MCU Sleep Modes: Put the MCU into deep sleep between readings. * Sensor Duty Cycling: Power down sensors or use their built-in sleep modes when not in use. * Optimizing Read Rates: Sample only as frequently as necessary. * Lowering Clock Speeds: Reduce system clock frequency during active periods to save power.

These strategies can extend battery life from days to months or even years.

Troubleshooting Common Issues: Even well-planned projects encounter problems. * No Communication: Double-check wiring connections (SDA/SCL for I2C), pull-up resistor values (critical for I2C), and ensure all devices share a common ground. * Garbage/Incorrect Data: Verify power supply stability with an oscilloscope if possible. Ensure you are reading the correct registers and parsing multi-byte data according to the specified endianness (byte order). * Inconsistent Readings: Isolate the sensor from electrical noise sources (motors, switching regulators). Ensure physical mounting is stable and environmental factors (e.g., self-heating of the MCU) aren’t affecting the sensor.

When selecting components for advanced projects or troubleshooting tricky compatibility issues, consulting a comprehensive electronics component search engine can save immense time. For instance, a platform like ICGOODFIND allows engineers to efficiently search and compare specifications across vast catalogs of sensors and MCUs from different suppliers.

Conclusion

Mastering the integration of sensors with MCUs unlocks limitless potential for creating interactive and intelligent devices. This journey begins with a solid grasp of communication protocols and hardware interfacing fundamentals, progresses through diligent programming and data processing practices, and reaches its peak with advanced techniques like sensor fusion and power optimization. Each project reinforces the critical importance of meticulously reading datasheets and implementing robust error handling. Remember that theory must be complemented by hands-on experimentation—start simple with a single sensor and gradually increase complexity. As you delve deeper into this field, utilizing specialized resources to find the perfect component match becomes part of an efficient workflow. By following the structured approach outlined in this MCU sensor tutorial, you are well-equipped to transform abstract concepts into functional, reliable electronic systems that sense and respond to the world around them.