The STC51 Series MCU: A Comprehensive Guide to Embedded Systems Development

Introduction

The STC51 Series MCU represents one of the most enduring and widely-used microcontroller families in the embedded systems landscape. Based on the classic 8051 architecture, these microcontrollers have evolved significantly while maintaining backward compatibility, making them a popular choice for both educational purposes and industrial applications. The STC51 Series MCU combines cost-effectiveness with robust performance, offering developers a reliable platform for everything from simple control systems to complex IoT devices. As technology continues to advance, the STC51 Series MCU has adapted with enhanced features while preserving the familiar development environment that engineers have trusted for decades. This article explores the architecture, key features, programming methodologies, and practical applications of this remarkable microcontroller series, with particular attention to how platforms like ICGOODFIND can streamline the development process for engineers working with these components.

Main Body

Part 1: Architecture and Technical Specifications

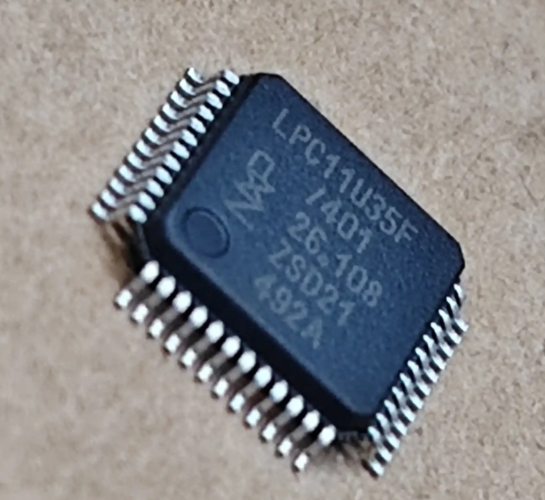

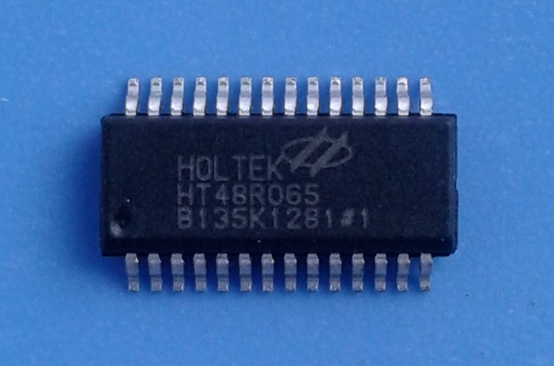

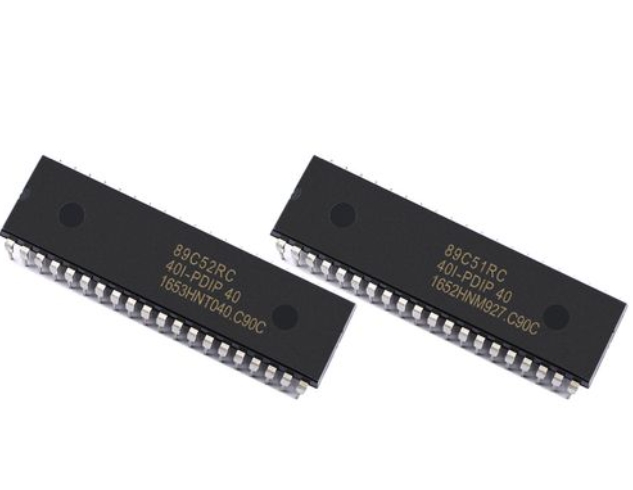

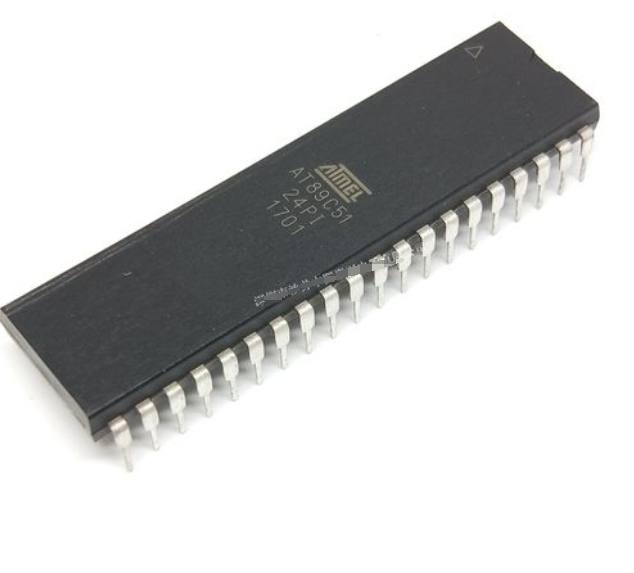

The foundation of the STC51 Series MCU lies in its enhanced 8051 core architecture, which maintains instruction set compatibility while introducing significant improvements over traditional 8051 microcontrollers. At the heart of these devices is an 8-bit CPU core that operates at clock frequencies typically ranging from 11.0592 MHz to 35 MHz, with some enhanced models capable of reaching even higher speeds. The memory architecture includes Flash program memory ranging from 4KB to 64KB, SRAM from 512 bytes to 4KB, and often additional EEPROM for data storage—substantial upgrades over original 8051 counterparts.

One of the most significant architectural enhancements in the STC51 Series MCU is the elimination of the traditional machine cycle concept. While classic 8051 microcontrollers required 12 clock cycles per instruction, most STC51 devices execute instructions in just 1-4 clock cycles, resulting in a dramatic performance improvement of 6-12 times compared to standard 8051 chips. This enhanced execution speed makes the STC51 suitable for applications that would traditionally require more powerful and expensive microcontrollers.

The peripheral set integrated into the STC51 Series MCU is particularly impressive. Most variants include multiple full-duplex UARTs for serial communication, SPI and I²C interfaces for connecting to peripheral devices, PWM outputs for precise motor control and analog simulation, a built-in watchdog timer for improved system reliability, and an advanced ADC (Analog-to-Digital Converter) with 8-10 bit resolution. The inclusion of these peripherals significantly reduces external component requirements and system cost while improving overall reliability—a crucial consideration for commercial products.

Power management represents another area where the STC51 Series MCU excels. These microcontrollers typically offer multiple power-saving modes, including Idle Mode and Power-Down Mode, which dramatically reduce power consumption when full processing power isn’t required. This feature makes them particularly suitable for battery-powered and energy-harvesting applications where extending operational life is paramount. The ability to wake from power-down mode via external interrupts, timer events, or serial communication allows designers to create systems that balance responsiveness with energy efficiency.

Part 2: Development Ecosystem and Programming Techniques

The development environment for the STC51 Series MCU benefits from mature toolchains and extensive community support. Programmers can choose from various IDEs (Integrated Development Environments), with Keil μVision being one of the most popular commercial options and SDCC (Small Device C Compiler) serving as a capable open-source alternative. The familiarity of the 8051 architecture means that countless libraries, code examples, and troubleshooting resources are available to accelerate development—a significant advantage for both beginners and experienced engineers.

Efficient programming practices are essential when working with the STC51 family. Despite performance enhancements, these remain 8-bit microcontrollers with limited resources compared to modern 32-bit alternatives. Developers must therefore employ optimization techniques such as using the smallest appropriate data types (uint8_t instead of int where possible), minimizing interrupt service routine execution time, leveraging the hardware peripherals instead of software implementations when feasible, and carefully managing memory allocation. These practices ensure that applications remain responsive while fitting within the constrained resources of embedded systems.

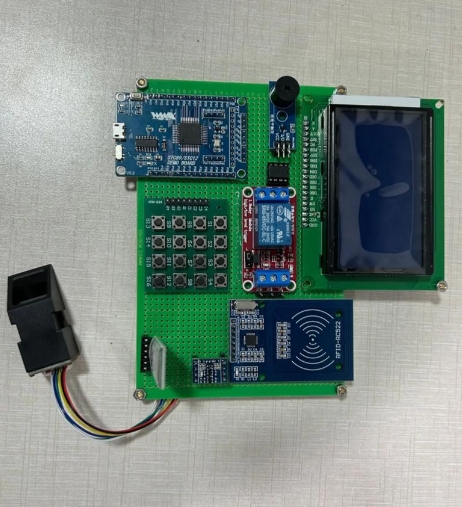

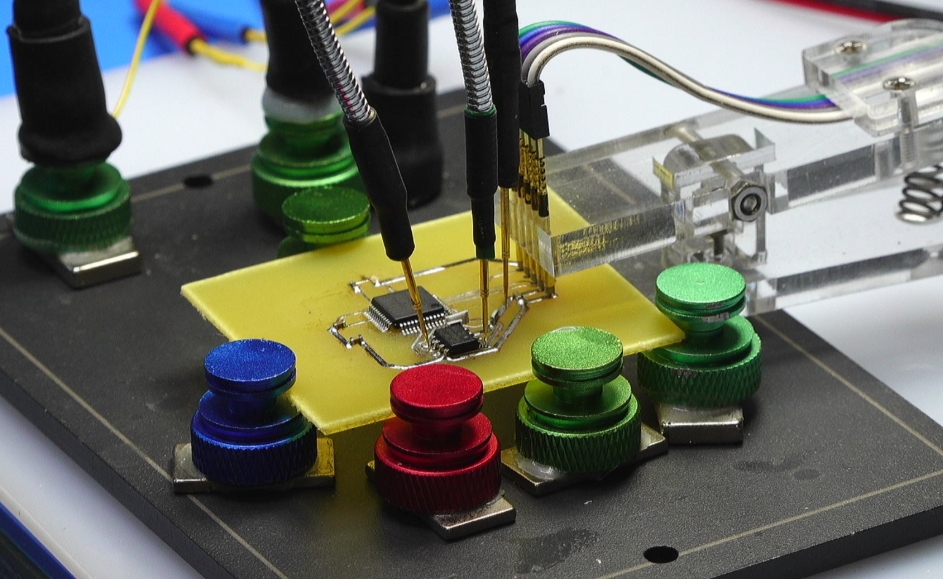

The programming interface for the STC51 Series MCU deserves special attention. Unlike many modern microcontrollers that require expensive programmers, most STC51 devices can be programmed through a simple UART interface using only a MAX232 level converter or similar circuitry. This feature significantly lowers the barrier to entry and reduces development costs. The programming process typically involves placing the microcontroller in bootloader mode by cycling power while holding certain pins at specific levels, then transferring the hex file through a serial connection—a straightforward process that has contributed to the series’ popularity in educational settings.

Debugging capabilities have improved in recent STC51 variants, with some models offering hardware debugging support through additional interfaces. However, many developers still rely on time-tested techniques such as toggling GPIO pins to measure execution timing or sending debug information through UART interfaces. When sourcing components and development tools for STC51 projects, platforms like ICGOODFIND can be invaluable for identifying reliable suppliers, comparing specifications across variants, and accessing technical documentation—significantly accelerating the procurement and development process.

Part 3: Applications and Real-World Implementation

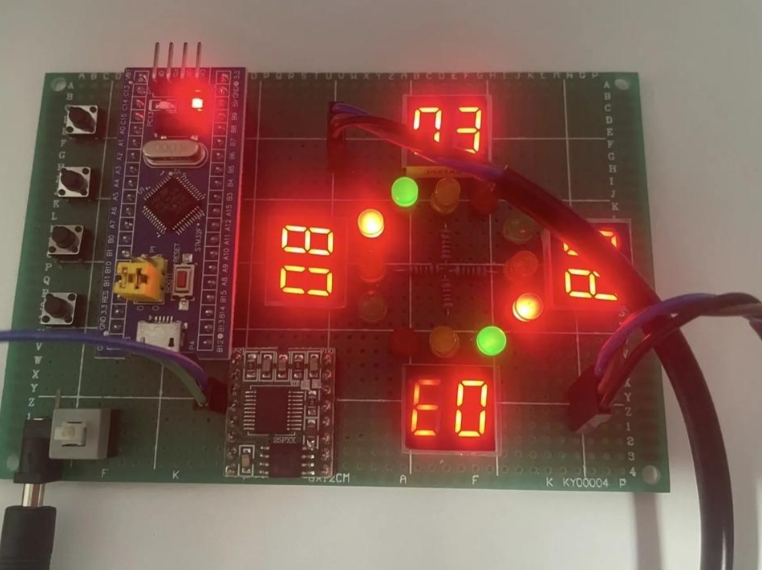

The practical applications of the STC51 Series MCU span countless industries and use cases, demonstrating their versatility and reliability. In industrial automation, these microcontrollers serve as the brains behind motor control systems, sensor interfaces, programmable logic controllers (PLCs), and monitoring equipment. Their robustness in harsh electrical environments, wide operating temperature ranges (-40°C to +85°C for industrial-grade variants), and noise immunity make them suitable for factory floor applications where reliability is non-negotiable.

Consumer electronics represent another significant application domain for the STC51 Series MCU. From kitchen appliances and power tools to remote controls and electronic toys, these microcontrollers provide cost-effective control solutions without sacrificing capability. Their integrated peripherals—particularly PWM outputs for motor speed control and LED dimming, ADC channels for reading sensors and potentiometers, and communication interfaces for connectivity—make them ideal for products where component count and manufacturing cost directly impact commercial viability.

The Internet of Things (IoT) has emerged as a growing application area for enhanced STC51 variants featuring integrated WiFi or Ethernet controllers. While limited in raw processing power compared to dedicated IoT chipsets, the STC51’s low power consumption, small footprint, and cost-effectiveness make it suitable for simple connected devices that don’t require complex data processing. Examples include environmental sensors, smart switches, agricultural monitoring systems, and basic home automation controllers—applications where continuous operation with minimal energy consumption is more important than high-speed data processing.

When implementing STC51 Series MCU in real-world projects, several design considerations emerge as critical success factors. Power supply design must account for clean power delivery with proper decoupling capacitors placed close to the microcontroller pins. Clock circuit design should balance accuracy requirements with cost considerations—using external crystals when timing precision is crucial or internal RC oscillators when acceptable. PCB layout must follow best practices for mixed-signal designs, separating analog and digital grounds while minimizing noise coupling. Input protection circuits are essential for interfaces connecting to external sensors or actuators in electrically noisy environments. For engineers navigating these implementation challenges while sourcing components, platforms like ICGOODFIND provide valuable resources for comparing parts, accessing application notes, and identifying proven reference designs.

Conclusion

The STC51 Series MCU continues to be a relevant and valuable option in the embedded systems landscape decades after its architectural predecessor was introduced. Its enduring popularity stems from an effective combination of backward compatibility with continuous innovation—offering developers a familiar programming model while delivering significantly enhanced performance and peripheral integration compared to traditional 8051 microcontrollers. The extensive ecosystem of development tools, code libraries, and community knowledge further lowers barriers to implementation across diverse applications from industrial control to consumer products.

As embedded systems continue to evolve toward greater connectivity and intelligence, the role of workhorse microcontrollers like the STC51 remains secure for applications where extreme processing power is unnecessary but reliability, cost-effectiveness, and power efficiency are paramount. The ongoing development of new variants with enhanced features ensures that this microcontroller family will continue serving engineers’ needs for years to come. For those embarking on STC51-based projects comprehensive resources available through platforms like ICGOODFIND can significantly streamline both the development process and component sourcing ultimately contributing to more successful project outcomes.