Unlocking the Power of STC MCU: A Comprehensive Guide to Enhanced Embedded Systems

Introduction

In the rapidly evolving world of embedded systems and microcontroller technology, STC Microcontroller Units (MCUs) have emerged as a powerful and versatile solution for engineers, developers, and electronics enthusiasts worldwide. As the demand for efficient, cost-effective, and high-performance computing solutions continues to grow across industries, understanding the capabilities and applications of STC MCUs becomes increasingly crucial. These Chinese-developed microcontrollers have gained significant traction in recent years, offering a compelling alternative to more established Western counterparts while providing unique features tailored to diverse application needs. This comprehensive guide delves deep into the world of STC microcontroller technology, exploring its architecture, advantages, programming methodologies, and real-world implementations. Whether you’re a seasoned embedded systems engineer or an electronics hobbyist looking to expand your knowledge, this article will provide valuable insights into how STC MCUs can transform your projects and why they deserve consideration in your next design. The growing ecosystem around these components, including resources from platforms like ICGOODFIND, further enhances their accessibility and implementation potential across various technological domains.

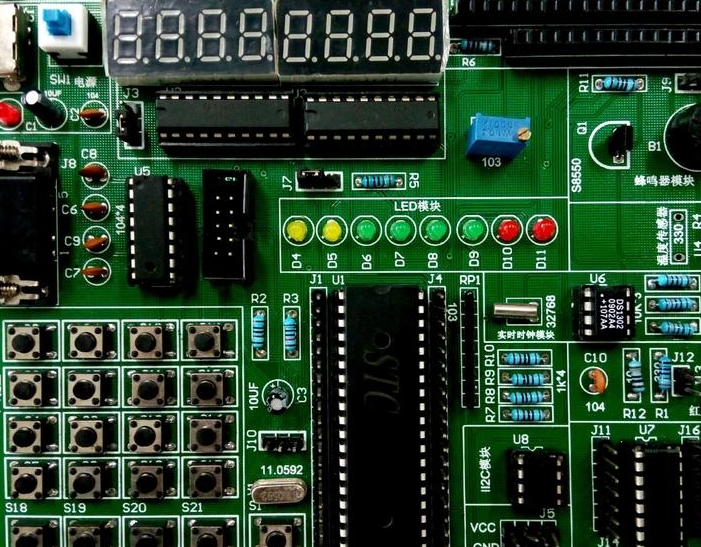

Part 1: Understanding STC MCU Architecture and Core Features

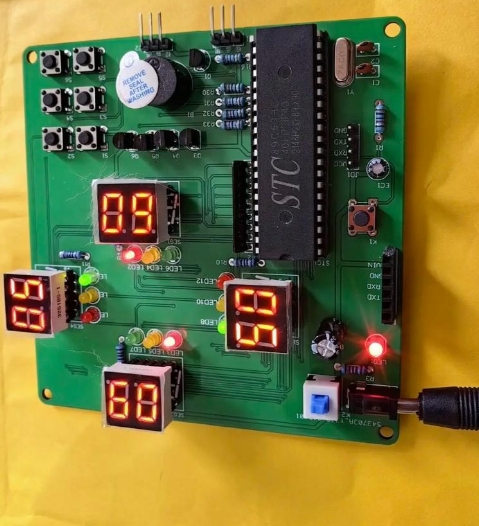

STC Microcontrollers represent a significant achievement in China’s semiconductor industry, developed by STC Microelectronics with a focus on combining performance, reliability, and affordability. At their core, STC MCUs are based on the 8051 microcontroller architecture, but with substantial enhancements that address many of the limitations of the original design while maintaining backward compatibility. This strategic approach allows developers familiar with the 8051 ecosystem to transition smoothly while benefiting from improved performance characteristics.

The architectural foundation of STC MCUs begins with their CPU core, which typically operates at higher clock speeds compared to traditional 8051 microcontrollers. While original 8051 chips executed most instructions in 12 clock cycles, modern STC variants often achieve execution in single clock cycles for many instructions, representing a significant performance boost. This enhanced processing capability enables STC MCUs to handle more complex tasks and algorithms without requiring external processing components, making them suitable for applications ranging from simple control systems to sophisticated IoT devices.

Memory configuration represents another critical aspect of STC microcontroller architecture. These chips typically integrate substantial flash memory for program storage, ranging from a few kilobytes to several hundred kilobytes depending on the specific series and model. This onboard program memory eliminates the need for external ROM chips in most applications, simplifying board design and reducing component count. Additionally, STC MCUs incorporate SRAM for data storage during operation, with sizes varying across the product lineup to accommodate different application requirements. Some advanced models also include EEPROM emulation capabilities using their flash memory, providing non-volatile storage for configuration data and parameters that must persist between power cycles.

The peripheral set integrated into STC MCUs represents one of their strongest advantages. Most variants include multiple universal asynchronous receiver-transmitters (UARTs) for serial communication, enabling connections to various sensors, communication modules, and computer interfaces. The inclusion of Serial Peripheral Interface (SPI) and Inter-Integrated Circuit (I2C) interfaces further expands connectivity options, allowing seamless integration with peripheral chips and sensor arrays. For analog signal acquisition, many STC microcontrollers incorporate Analog-to-Digital Converters (ADCs) with resolutions typically ranging from 8 to 12 bits, enabling direct measurement of analog sensors without external conversion components.

Timer/counter units form another essential component of the STC MCU peripheral suite. These hardware timers serve multiple purposes, from generating precise delays and measuring time intervals to creating pulse-width modulation (PWM) signals for motor control and LED dimming applications. Advanced STC models often include specialized timer configurations capable of capturing input pulses, generating complementary PWM outputs for motor drive applications, and even supporting encoder interfaces for position feedback systems.

The digital I/O capabilities of STC microcontrollers deserve special attention. Most STC MCUs offer numerous general-purpose input/output pins that can be configured through software to serve different functions. These pins typically support multiple operating modes, including quasi-bidirectional, push-pull output, open-drain, and high-impedance input configurations. This flexibility allows designers to interface with a wide range of external components without requiring additional level-shifting or signal conditioning circuitry in many cases.

Power management features have become increasingly sophisticated in recent STC MCU generations. Many models support multiple low-power operating modes, including idle and power-down states that significantly reduce current consumption during periods of inactivity. These power-saving capabilities make STC microcontrollers particularly suitable for battery-powered and energy-harvesting applications where extended operational lifetime is crucial.

Part 2: Advantages of Choosing STC MCUs for Your Projects

The decision to incorporate STC Microcontroller Units into electronic designs offers numerous compelling advantages that extend beyond simple cost considerations. One of the most significant benefits lies in the exceptional cost-to-performance ratio that STC MCUs deliver. Compared to microcontrollers from Western manufacturers with similar specifications, STC variants often provide substantial cost savings without compromising on features or reliability. This economic advantage becomes particularly important in price-sensitive applications or high-volume production scenarios where even marginal component cost reductions can significantly impact overall project economics.

Robust ecosystem support represents another key advantage of the STC microcontroller platform. Despite being manufactured by a Chinese company, STC MCUs enjoy extensive documentation availability in multiple languages, active user communities across various online platforms, and growing manufacturer support resources. The development tools required for programming and debugging STC microcontrollers are generally affordable and accessible, with both official programming devices from STC Microelectronics and third-party alternatives available in the market. This ecosystem maturity reduces barriers to entry for new adopters and accelerates the learning curve for development teams transitioning from other microcontroller platforms.

The enhanced 8051 compatibility of STC MCUs provides a unique advantage for engineers familiar with this longstanding architecture. While incorporating significant performance improvements and additional features, STC microcontrollers maintain a high degree of compatibility with the original 8051 instruction set and programming model. This backward compatibility allows developers to leverage existing code bases, development tools, and technical knowledge while benefiting from modern performance characteristics. For educational institutions teaching embedded systems fundamentals, this combination of traditional architecture understanding with contemporary performance capabilities creates an ideal learning platform.

When it comes to electrical characteristics and reliability, STC microcontrollers demonstrate impressive specifications that meet or exceed industry standards. Many STC MCU variants feature wide operating voltage ranges, typically from 2.4V to 5.5V, providing flexibility in power supply design and enabling operation from various battery configurations. The operating temperature ranges offered by standard STC components suit most commercial and industrial applications, with extended temperature options available for more demanding environments. Additionally, STC Microelectronics has implemented robust electrostatic discharge (ESD) protection and latch-up immunity in their designs, enhancing field reliability in electrically noisy environments.

The integration level achieved in STC microcontroller designs contributes significantly to their application advantages. By incorporating numerous peripheral functions directly onto the chip silicon, STC MCUs reduce system component count and simplify printed circuit board layouts. This integration extends beyond standard communication interfaces and timers to include specialized functions such as real-time clocks, watchdog timers, power monitoring circuits, and in some advanced models, dedicated cryptographic accelerators for security-sensitive applications. This comprehensive integration approach results in more compact final products with improved reliability due to reduced interconnection complexity.

For developers working on rapid prototyping projects or facing tight development schedules, STC microcontrollers offer distinct advantages through their straightforward programming model and minimal external component requirements. Many basic STC MCU applications can be implemented with just the microcontroller chip, a crystal oscillator or ceramic resonator (though many models include internal oscillators), bypass capacitors, and a power supply. This simplicity accelerates initial proof-of-concept development and facilitates design iterations during the prototyping phase.

The security features implemented in STC microcontrollers deserve mention as another significant advantage. Understanding the importance of intellectual property protection in commercial products, STC Microelectronics has incorporated multiple security mechanisms into their chips. These typically include code read protection features that prevent unauthorized extraction of firmware from programmed devices—an essential consideration for products facing potential reverse engineering threats. Some advanced STC models offer additional security enhancements such as unique device identifiers and hardware encryption support.

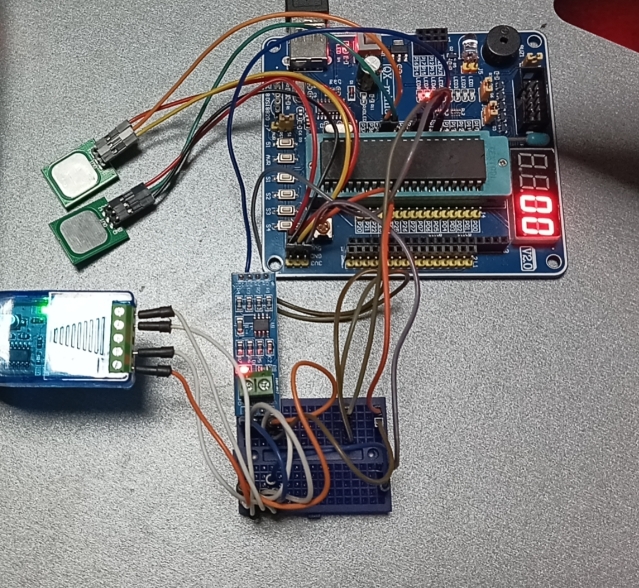

Part 3: Programming Methodologies and Real-World Applications

Successfully implementing projects with STC Microcontroller Units requires understanding their programming methodologies and development ecosystem. The primary programming approach for STC MCUs involves using the ISP (In-System Programming) capability that these chips incorporate. Unlike many microcontrollers that require external programming hardware, most STC variants can be programmed directly through a serial interface (typically UART) using a simple level-shifting circuit or dedicated programming adapter. This ISP functionality significantly simplifies the development process by allowing firmware updates without removing the microcontroller from its circuit board—a particular advantage during debugging cycles and field updates.

The software development environment for STC microcontrollers primarily revolves around the Keil C51 development tools, which provide comprehensive support for the enhanced 8051 architecture used in STC chips. While commercial versions of Keil MDK offer advanced debugging capabilities, freely available evaluation versions provide sufficient functionality for many development projects. Alternative development environments including IAR Embedded Workbench and SDCC (Small Device C Compiler) also support STC microcontrollers, offering developers flexibility in toolchain selection based on preferences and project requirements.

When it comes to programming languages, most STC MCU development occurs using C language due to its optimal balance between hardware control capabilities and programming efficiency. The availability of mature C compilers specifically optimized for the 8051 architecture ensures efficient code generation that leverages the enhanced features of STC microcontrollers while maintaining compatibility with existing code bases. For maximum performance in critical sections or direct hardware manipulation, developers can incorporate assembly language routines within primarily C-based projects—an approach that combines development efficiency with precise hardware control when necessary.

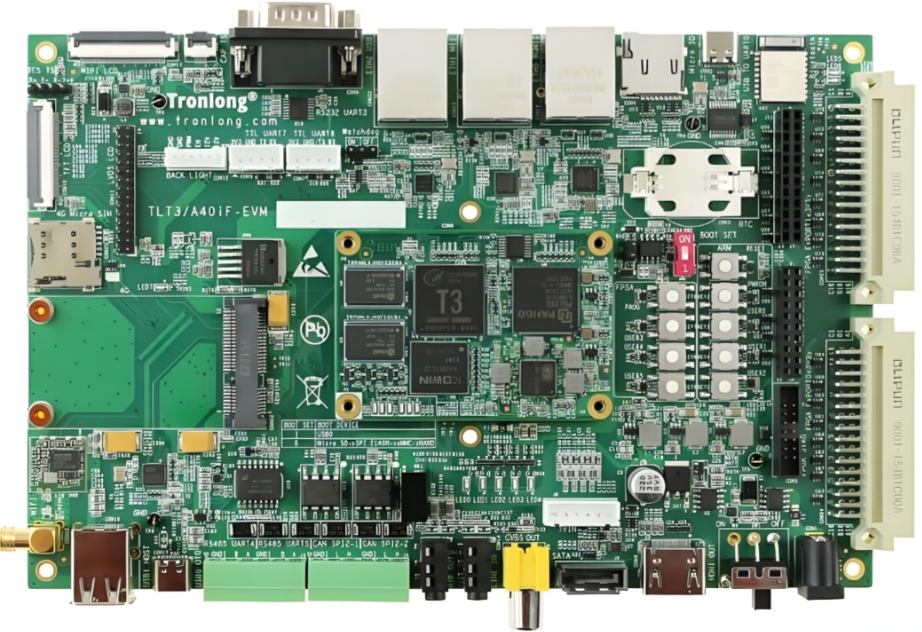

The practical applications of STC Microcontroller Units span an impressively diverse range of industries and product categories. In the consumer electronics sector, STC MCUs frequently appear in appliances, power tools, lighting control systems, and various household gadgets where their combination of performance features and cost-effectiveness delivers compelling value propositions. Their robust I/O capabilities suit them particularly well for control-oriented applications requiring multiple sensor inputs and actuator outputs.

The industrial automation domain represents another significant application area for STC microcontroller technology. Here, features such as reliable operation in electrically noisy environments, extended temperature range support (in specific variants), and precise timing capabilities make STC MCUs suitable for motor control systems, sensor interfaces, programmable logic controllers (PLCs), and industrial monitoring equipment. The availability of enhanced communication peripherals in many STC models facilitates integration into industrial networks using protocols such as Modbus.

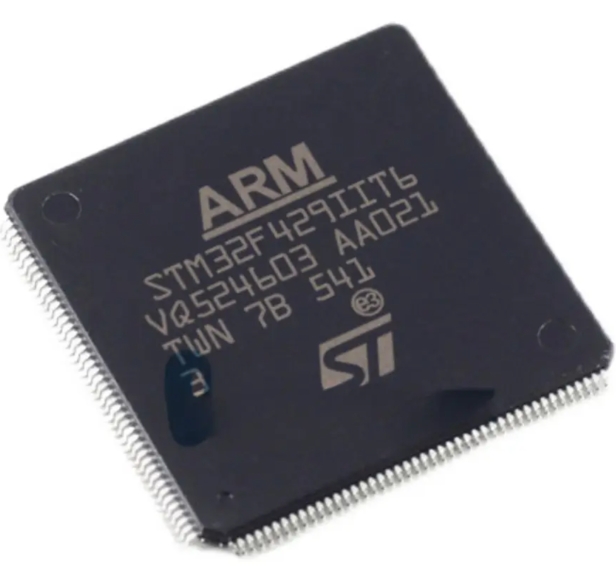

In the rapidly expanding Internet of Things (IoT) landscape, select STC MCU variants with appropriate power management characteristics find application in connected sensor nodes, edge computing devices, and smart infrastructure components. While not all STM microcontrollers include built-in wireless connectivity, their serial communication interfaces readily interface with external Wi-Fi, Bluetooth, LoRaWAN®, or cellular modules to create comprehensive IoT solutions. The low-power operating modes available in many STM chips extend battery life in portable or remotely deployed IoT devices.

The automotive electronics sector represents an increasingly important application domain for STC microcontroller technology—particularly in aftermarket accessories and non-safety-critical systems within vehicles. Examples include automotive lighting control modules; entertainment system interfaces; basic sensor monitoring systems; and comfort/convenience features where cost sensitivity exists alongside reliability requirements.

For developers seeking components or technical resources for their STC MCU projects platforms like ICGOODFIND offer valuable services by connecting engineers with appropriate suppliers documentation and community knowledge related to these microcontrollers streamlining the component sourcing process particularly during prototype development phases when small quantity availability becomes crucial

Educational institutions worldwide have embraced STMCU technology for teaching embedded systems concepts due to their approachable architecture comprehensive documentation availability affordable development tools making them ideal platforms for introducing students to microcontroller fundamentals while preparing them for industrial environments where these components see increasing adoption

Conclusion

STC Microcontroller Units have firmly established themselves as viable competitive options in the global microcontroller landscape offering compelling combinations of performance features reliability and cost-effectiveness that suit diverse application requirements From their enhanced 8051-compatible architecture through their extensive peripheral integration to their straightforward development methodology these Chinese-developed microcontrollers deliver substantial value across numerous market segments

The continuing evolution of STCMCU technology demonstrates commitment fromSTCMicroelectronics toward addressing developer needs while incorporating contemporary features demanded by modern electronic designs With growing international recognition improving documentation availability expanding third-party tool support these components present increasingly attractive alternatives particularly for cost-sensitive applications without compromising capability requirements

As embedded systems continue proliferating across consumer industrial automotive IoT domains understanding capabilities offered bySTCMCU technology becomes increasingly valuable forengineers developers decision-makers involved electronic product development The comprehensive ecosystem surrounding these components including resources available through platforms like ICGOODFIND further enhances accessibility implementation potential ensuringSTCMicrocontroller Units remain relevant consideration future embedded designs across multiple industries.