The Ultimate Guide to ATmega16 MCU: Features, Applications, and Development

Introduction

The ATmega16 MCU stands as a pivotal component in the landscape of embedded systems and microcontroller technology. As an 8-bit microcontroller based on the AVR enhanced RISC architecture, the ATmega16 has established itself as a workhorse in numerous electronic applications, from industrial automation to educational projects. Manufactured by Microchip Technology (formerly Atmel Corporation), this microcontroller combines high performance with low power consumption, making it an ideal choice for both beginners and experienced engineers. The ATmega16’s enduring popularity stems from its robust feature set, ease of programming, and extensive community support. In this comprehensive guide, we will explore the technical specifications, practical applications, and development ecosystem of this versatile microcontroller, demonstrating why it remains relevant in today’s rapidly evolving technological landscape. Whether you’re a student embarking on your first embedded project or a professional seeking reliable control solutions, understanding the ATmega16 MCU provides a solid foundation for electronic design and innovation.

Part 1: Technical Specifications and Architecture

The ATmega16 MCU boasts an impressive array of technical features that contribute to its widespread adoption across various industries. At its core, the microcontroller operates at up to 16MHz clock frequency, delivering approximately 16 MIPS (Million Instructions Per Second) throughput, which provides ample processing power for most embedded applications. The heart of the ATmega16 is its advanced AVR RISC architecture, which executes powerful instructions in a single clock cycle, resulting in impressive computational efficiency compared to other 8-bit microcontrollers in its class.

One of the most significant features of the ATmega16 is its 16KB of in-system programmable Flash memory for program storage. This non-volatile memory can be rewritten up to 10,000 times, allowing for extensive program development and updates throughout the product lifecycle. Complementing this is 1KB of SRAM for data storage during program execution and 512 bytes of EEPROM for critical data that must be retained even when power is removed. This memory configuration strikes an excellent balance for moderate complexity applications while maintaining cost-effectiveness.

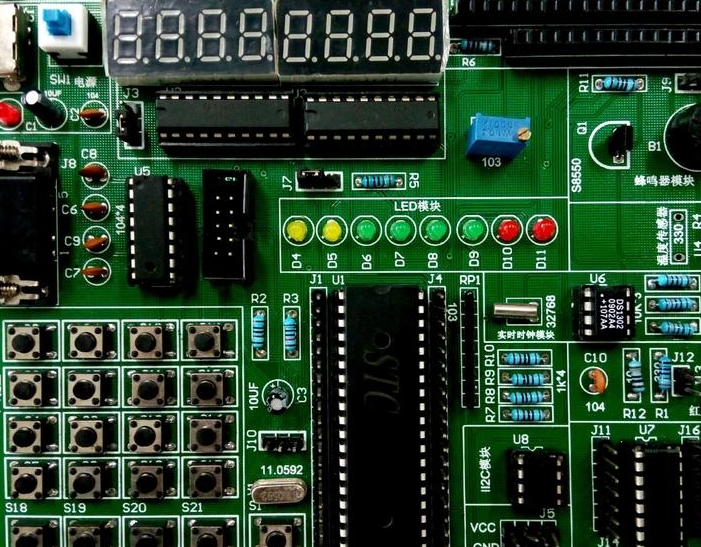

The input/output capabilities of the ATmega16 are particularly noteworthy. The microcontroller features 32 programmable I/O lines distributed across four ports (A, B, C, and D), each serving multiple functions. Port A primarily functions as an 8-channel ADC input, while Port B, C, and D offer versatile digital I/O capabilities with alternate functions for various peripherals. These include PWM channels, external interrupts, communication interfaces, and more. The flexible I/O structure allows designers to maximize functionality without requiring external components.

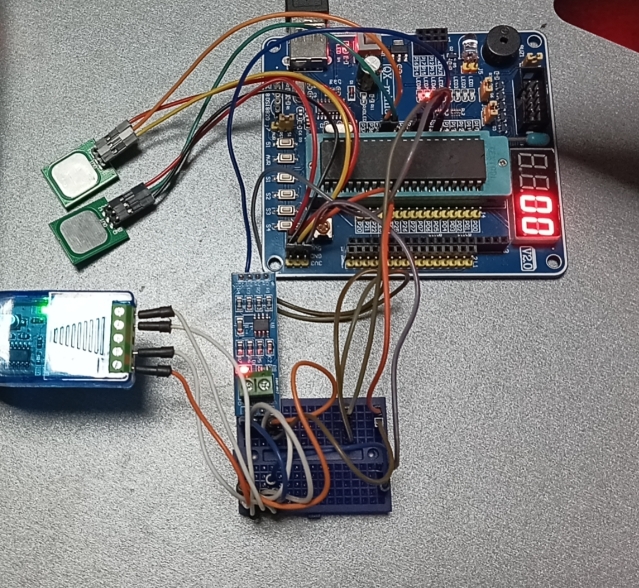

Peripheral integration is another area where the ATmega16 excels. It incorporates multiple communication interfaces including USART (Universal Synchronous/Asynchronous Receiver/Transmitter) for serial communication, SPI (Serial Peripheral Interface) for high-speed communication with peripherals, and a TWI (Two-Wire Interface) compatible with I²C protocol for connecting multiple devices on a bus. Additionally, the microcontroller includes four PWM channels, an 8-channel 10-bit ADC (Analog-to-Digital Converter), analog comparator, watchdog timer with independent oscillator, and multiple timer/counters with compare modes.

The power management features of the ATmega16 contribute significantly to its versatility in power-constrained applications. It operates within a voltage range of 4.5V to 5.5V (at full speed) but can function at lower voltages with reduced performance. The device incorporates multiple sleep modes including Idle, ADC Noise Reduction, Power-save, Power-down, and Standby modes, allowing developers to minimize power consumption during inactive periods. These features make the ATmega16 suitable for battery-powered devices and energy-efficient applications where power conservation is critical.

Part 2: Practical Applications and Implementation

The versatility of the ATmega16 MCU has led to its implementation across a diverse range of applications spanning multiple industries. In the industrial automation sector, the microcontroller serves as the brain behind numerous control systems, including PLCs (Programmable Logic Controllers), motor control units, sensor interfaces, and process monitoring equipment. Its robust I/O capabilities and communication interfaces enable seamless integration with industrial networks and peripheral devices. The real-time control capabilities, facilitated by multiple timer/counters and interrupt sources, allow for precise timing operations essential in industrial environments.

In consumer electronics, the ATmega16 finds application in various devices due to its cost-effectiveness and adequate processing power. It commonly appears in home automation systems, security systems, smart appliances, and entertainment devices. For instance, the microcontroller can manage climate control systems by processing inputs from temperature and humidity sensors while controlling actuators like relays and motors. The integrated ADC enables direct interface with analog sensors without requiring external conversion components, simplifying design and reducing bill-of-materials costs.

The educational sector represents another significant application area for the ATmega16 MCU. Its straightforward architecture and extensive documentation make it an excellent platform for teaching embedded systems concepts. Many universities and technical institutes incorporate the ATmega16 into their curricula through development boards and experimentation kits. Students learn fundamental concepts such as digital I/O control, analog-to-digital conversion, interrupt handling, and communication protocols using this microcontroller as their primary platform.

When implementing projects with the ATmega16 MCU, several best practices ensure optimal performance and reliability. Proper power supply decoupling is crucial, typically achieved by placing 100nF ceramic capacitors close to each power pin pair and additional bulk capacitance near the main power entry point. For applications using the internal or external crystal oscillator, keeping the crystal close to the microcontroller with appropriate load capacitors minimizes noise and ensures stable operation. Additionally, implementing watchdog timer routines protects against software hangs in critical applications.

For developers seeking resources and components for ATmega16 projects, specialized platforms like ICGOODFIND offer comprehensive solutions. This platform provides access to authentic components, development tools, and technical documentation essential for successful project implementation. Through such specialized distributors, engineers can source genuine ATmega16 microcontrollers along with compatible development boards, programmers, and peripheral modules that accelerate development cycles.

Real-world case studies demonstrate the effectiveness of ATmega16 implementations across various domains. In one industrial application, the microcontroller was deployed in an automated packaging system where it coordinated multiple stepper motors, read barcode scanners via USART interfaces, monitored safety sensors through digital inputs, and communicated with a central supervisory system using MODBUS protocol over RS-485. The project leveraged the ATmega16’s multiple hardware PWM outputs for precise motor control while utilizing its USART in multi-processor communication mode to manage peripheral nodes.

Part 3: Development Ecosystem and Programming

The development ecosystem surrounding the ATmega16 MCU is mature and well-supported, offering developers multiple pathways for programming and debugging their applications. At the core of this ecosystem is the AVR toolchain, which includes compilers, assemblers, linkers, and debuggers compatible with various development environments. The most common programming language for ATmega16 development is C/C++, utilizing compilers such as AVR-GCC which provides optimized code generation specifically for the AVR architecture.

Several integrated development environments (IDEs) support ATmega16 programming effectively. Atmel Studio (now Microchip Studio) serves as the official IDE from the manufacturer, offering comprehensive features including project management, code editing, compiling, debugging, and simulation capabilities. For developers preferring lightweight or cross-platform solutions, alternatives like PlatformIO or programming directly with AVR-GCC combined with text editors provide flexible options. Additionally, Arduino IDE with appropriate cores can be configured to program ATmega16 boards with some adaptations.

Programming the ATmega16 typically occurs through ISP (In-System Programming) using interfaces like SPI combined with specific reset control signals. This approach allows programming of the microcontroller after it has been soldered onto the target PCB using simple programmer hardware such as USBasp, AVRISP mkII, or Atmel-ICE. Alternatively, parallel programming offers another method for mass production environments where high-speed programming is essential. Bootloader implementation represents another popular approach that enables programming through standard communication interfaces like UART without requiring specialized programmer hardware.

The debugging capabilities available for ATmega16 development enhance productivity during project implementation. While the standard ATmega16 doesn’t include on-chip debug circuitry higher-end models in the series offer debugWIRE or JTAG interfaces for sophisticated debugging sessions. However,simulation tools like Proteus provide virtual execution environments where developers can test their code against simulated hardware before deploying to physical devices reducing development risks significantly.

A rich collection of libraries and code examples accelerates ATmega16 project development substantially.The AVR community has produced numerous open-source libraries for peripheral control communication protocol implementation mathematical functions and driver support for common external components.Platforms like GitHub host extensive code repositories while manufacturer websites provide datasheets application notes reference designs all contributing comprehensive resource collection developers.

For component sourcing development tools specialized distributors like ICGOODFIND offer reliable access genuine microcontrollers programmers evaluation boards essential successful project completion These platforms often provide additional value through technical support community forums design resources helping developers overcome implementation challenges efficiently The availability such specialized distribution channels ensures continued viability ATmega16 new existing projects despite emergence newer microcontroller families market

Conclusion

The ATmega16 MCU continues to demonstrate remarkable resilience in the rapidly evolving landscape of microcontroller technology.Despite being introduced decades ago its balanced combination performance peripherals cost-effectiveness maintains relevance wide spectrum applications From industrial controls educational platforms consumer products this versatile microcontroller proves capable handling diverse requirements embedded systems development

The comprehensive feature set including generous memory allocation multiple communication interfaces sophisticated timer counters flexible I/O structure positions ATmega16 compelling choice projects requiring robust control capabilities without excessive computational demands The extensive development ecosystem mature toolchain abundant learning resources further lower barriers entry both newcomers experienced engineers alike

As we’ve explored throughout this guide successful implementation ATmega16 projects requires understanding architectural capabilities practical application considerations available development tools By leveraging specialized resources available through platforms like ICGOODFIND developers can efficiently source components access technical support accelerate their development cycles Ultimately ATmega16 represents proven reliable solution embedded challenges standing test time continuing serve foundation innovation across industries skill levels.