The Ultimate Guide to PIC MCU: Powering Embedded Systems with Precision

Introduction

In the vast and intricate world of embedded systems and electronics, the choice of a microcontroller (MCU) can make or break a project. Among the plethora of options available, one family has consistently stood out for its robustness, versatility, and enduring popularity: the PIC MCU. Developed by Microchip Technology, PIC (Peripheral Interface Controller) microcontrollers have been the silent brains inside countless devices for decades, from simple household appliances to complex industrial automation systems. This article delves deep into the universe of PIC MCUs, exploring their architecture, key advantages, and the process of selecting the right one for your application. We will also touch upon how platforms like ICGOODFIND can be instrumental in navigating the complex component selection landscape. Whether you are a seasoned engineer or an enthusiastic hobbyist, understanding the capabilities of PIC microcontrollers is essential for innovating in today’s connected world.

Part 1: Understanding the Architecture and Core Strengths of PIC MCU

The enduring success of the PIC MCU is fundamentally rooted in its distinctive and efficient architecture. Unlike many other microcontrollers that use a Von Neumann architecture, most PIC MCUs are based on a Harvard architecture. This design philosophy separates the memory for program instructions and data, allowing the CPU to fetch both an instruction and data simultaneously in a single clock cycle. This results in significantly enhanced performance and throughput for a given clock speed, making PIC MCUs exceptionally fast for their class.

At the heart of every PIC microcontroller is its RISC (Reduced Instruction Set Computing) CPU core. The RISC philosophy means the processor understands a relatively small number of simple, highly optimized instructions. This simplicity translates into several tangible benefits. Firstly, it allows for efficient code generation, enabling compilers to produce compact and fast-executing programs. Secondly, it contributes to lower power consumption, as the hardware required to decode complex instructions is minimized. This combination of Harvard architecture and RISC core creates a powerhouse that is both swift and power-sipping, a critical requirement for battery-operated and energy-sensitive applications.

Another cornerstone of the PIC MCU ecosystem is its vast and varied peripheral set. Microchip has equipped its PIC families with an almost exhaustive list of integrated peripherals, which drastically reduces the need for external components, saving both board space and system cost. Key peripherals include: * Advanced Analog Capabilities: High-resolution Analog-to-Digital Converters (ADC), Digital-to-Analog Converters (DAC), and comparators are commonplace. * Flexible Communication Interfaces: Multiple UART, I2C, and SPI modules allow for seamless connectivity with sensors, displays, and other ICs. * Specialized Timers and PWM: Capture/Compare/PWM (CCP) modules and dedicated timers are essential for motor control, power management, and generating precise waveforms. * Core Independent Peripherals (CIPs): This is a revolutionary concept where peripherals can operate without constant intervention from the CPU. For example, a Configurable Logic Cell (CLC) can interconnect different peripherals to make decisions autonomously, freeing up the CPU for more complex tasks and further reducing power consumption.

This robust architectural foundation, combined with a “right-to-the-metal” programming approach, gives developers fine-grained control over the hardware, which is invaluable for time-critical and resource-constrained applications.

Part 2: Navigating the Expansive PIC MCU Product Families

One of the most daunting challenges for engineers is selecting the right microcontroller from a seemingly infinite array of options. Microchip has strategically organized its PIC MCU portfolio into distinct families to simplify this process, each targeting specific performance points and application domains.

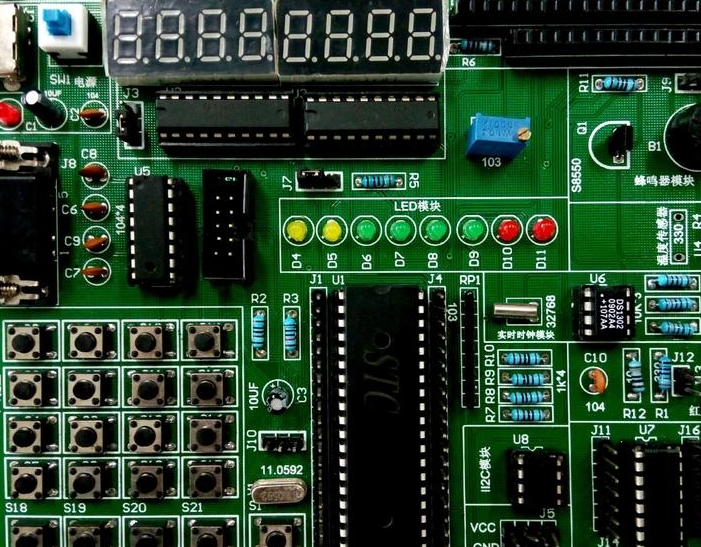

The 8-bit PIC MCUs form the bedrock of the series and are legendary for their cost-effectiveness and ease of use. Families like the PIC10, PIC12, PIC16, and PIC18 are ideal for applications that require straightforward control logic, basic sensing, and user interface functions. They are the workhorses found in consumer electronics, automotive body controls, and smart sensors. Their simplicity makes them an excellent starting point for those new to embedded systems.

For applications demanding more computational muscle and larger memory footprints without migrating to a 32-bit ecosystem, the 16-bit PIC MCUs and dsPIC® Digital Signal Controllers (DSCs) are the perfect solution. The dsPIC DSCs, in particular, are a hybrid marvel. They combine the control-oriented features of a standard PIC MCU with the computational power of a Digital Signal Processor (DSP). This makes them exceptionally well-suited for real-time control algorithms in applications such as digital power conversion, motor control (e.g., precision control of BLDC motors), and advanced audio processing.

At the high-end performance tier lie the 32-bit PIC32 MCUs. Based on the MIPS processor core, these microcontrollers deliver performance that rivals many application processors. They are designed to handle complex tasks running on feature-rich operating systems like Linux or real-time operating systems (RTOS). With features like high-speed connectivity (Ethernet, USB), advanced graphics processing, and large memory arrays, the PIC32 family is the go-to choice for sophisticated applications including industrial networking, Internet of Things (IoT) gateways, and modern human-machine interfaces (HMIs).

With such diversity, making the optimal choice requires careful consideration of multiple factors: processing speed (DMIPS), flash/RAM size, peripheral mix (e.g., number of UARTs or ADC channels), power budget, and package size. This is where leveraging a comprehensive component search engine becomes invaluable. A platform like ICGOODFIND can dramatically accelerate this selection process by allowing engineers to filter Microchip’s entire catalog based on these precise technical parameters, ensuring they find a PIC MCU that is a perfect technical and commercial fit for their project.

Part 3: The Development Workflow and Ecosystem for PIC MCU

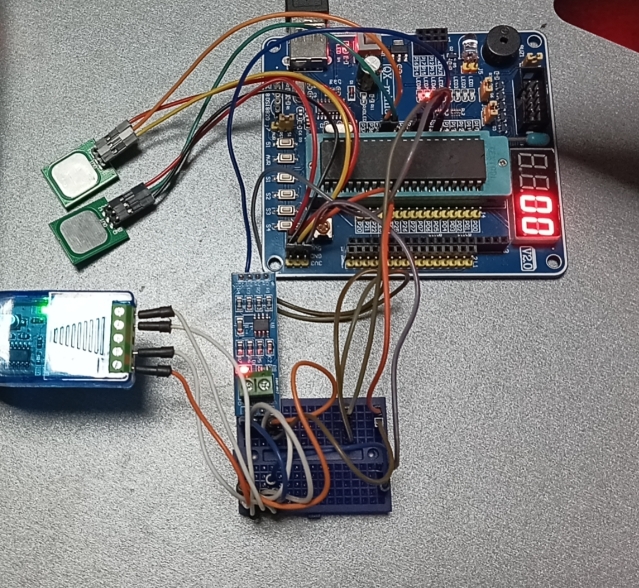

Bringing a concept to life with a PIC MCU is supported by a mature and comprehensive development ecosystem provided by Microchip and a vibrant third-party community. The journey typically begins with selecting a hardware development board. Microchip offers a wide range of evaluation kits and curiosity boards for nearly every PIC MCU family, providing a ready-made platform for prototyping and testing.

The software side is anchored by Microchip’s powerful Integrated Development Environment (IDE), MPLAB® X IDE. This free, feature-rich environment based on the NetBeans platform provides all the tools necessary for coding, debugging, and programming PIC MCUs. It supports both Microchip’s proprietary compilers, such as MPLAB XC, which are highly optimized for the PIC architecture, as well as third-party toolchains.

A critical tool within this ecosystem is the hardware programmer/debugger. Devices like the MPLAB ICD 5 or PICKit™ 4 allow developers to not only program the flash memory of the PIC MCU but also perform in-circuit debugging. This capability is indispensable; it allows engineers to step through code line-by-line while observing register values and variable states in real-time, dramatically reducing development time by quickly identifying logic errors and hardware integration issues.

Beyond the core tools, Microchip fosters innovation through its software frameworks. MPLAB Code Configurator (MCC) is a particularly impactful plugin for MPLAB X IDE. It provides a graphical interface to set up the microcontroller’s clock system, peripherals, and pin assignments. MCC generates initialization code automatically, eliminating tedious manual register configuration and minimizing potential human error. This allows developers to focus their efforts on writing application-specific logic rather than getting bogged down in low-level setup routines.

Finally, no development process is complete without robust documentation. Microchip provides an extensive collection of datasheets, family reference manuals, and application notes for every single PIC MCU. These documents are incredibly detailed and serve as the ultimate source of truth for understanding every facet of the microcontroller’s operation.

Conclusion

The PIC MCU has proven itself to be far more than just a component; it is a versatile and reliable platform that has empowered innovation across generations of electronic products. Its unique Harvard architecture combined with a RISC core delivers an exceptional balance of performance and power efficiency. The strategic segmentation into 8-bit, 16-bit/dsPIC®, and 32-bit families ensures that there is a suitable PIC MCU for virtually any application imaginable—from a simple blinking LED to a complex networked industrial controller. Supported by a mature ecosystem featuring powerful tools like MPLAB® X IDE and MPLAB Code Configurator®, developers are equipped to bring their ideas to market faster and more efficiently than ever before. As we continue to push the boundaries of what’s possible in embedded design through trends like IoT and AI at the edge platforms like ICGOODFIND will play an increasingly critical role in helping engineers navigate this complexity finding not just any component but exactly what they need ensuring their next project with a PIC MCU is built on a foundation of optimal choice.