Difference Between PLC and MCU

Introduction

In the world of industrial automation and embedded systems, two types of controllers reign supreme: the Programmable Logic Controller (PLC) and the Microcontroller Unit (MCU). While both are fundamental components that process inputs and control outputs, they are designed for vastly different environments and applications. For engineers, developers, and procurement specialists, understanding the distinction is not just academic—it’s critical for selecting the right tool for the job, ensuring system reliability, cost-effectiveness, and long-term maintainability. This confusion often arises because, at their core, both devices contain a microprocessor. However, the devil is in the details: the surrounding architecture, the operating environment, and the design philosophy. This article will dissect the key differences between PLCs and MCUs, providing a clear guide to help you make an informed decision for your next project. For those seeking specialized components in this domain, platforms like ICGOODFIND can be invaluable resources for sourcing reliable parts.

Main Body

Part 1: Core Architecture and Hardware Design

The most fundamental difference between a PLC and an MCU lies in their physical and architectural construction.

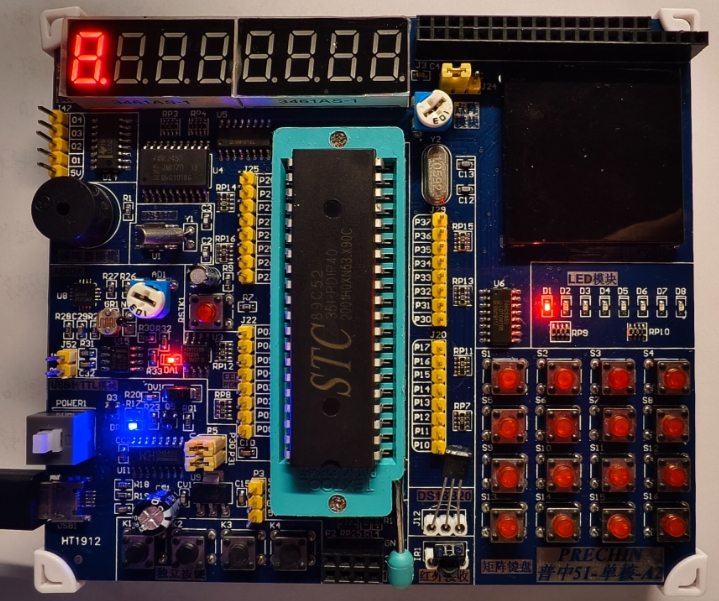

A Programmable Logic Controller (PLC) is a complete, self-contained industrial computer system. Its architecture is built around robustness and modularity. A typical PLC consists of several key modules: * Central Processing Unit (CPU): This is the brain, which executes the control program. While it may be based on a commercial microcontroller or microprocessor, it is heavily fortified. * Input/Output (I/O) Modules: These are separate, plug-in modules that handle the interface with the real world. They include digital I/O (for on/off signals like buttons and relays) and analog I/O (for continuous signals like temperature or pressure). A critical feature of these I/O modules is their built-in isolation and protection circuits. They are designed to withstand voltage spikes, electrical noise, and other harsh conditions common in industrial settings. * Power Supply Module: Provides clean, regulated power to the entire system, often with protection against power fluctuations. * Communication Modules: Allow the PLC to network with other PLCs, Human-Machine Interfaces (HMIs), and supervisory systems via protocols like EtherNet/IP, Profinet, or Modbus.

In essence, a PLC is a system-on-a-board (or rack), designed for easy integration and expansion.

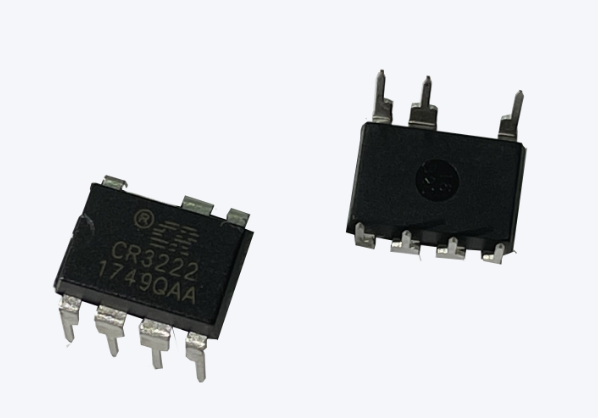

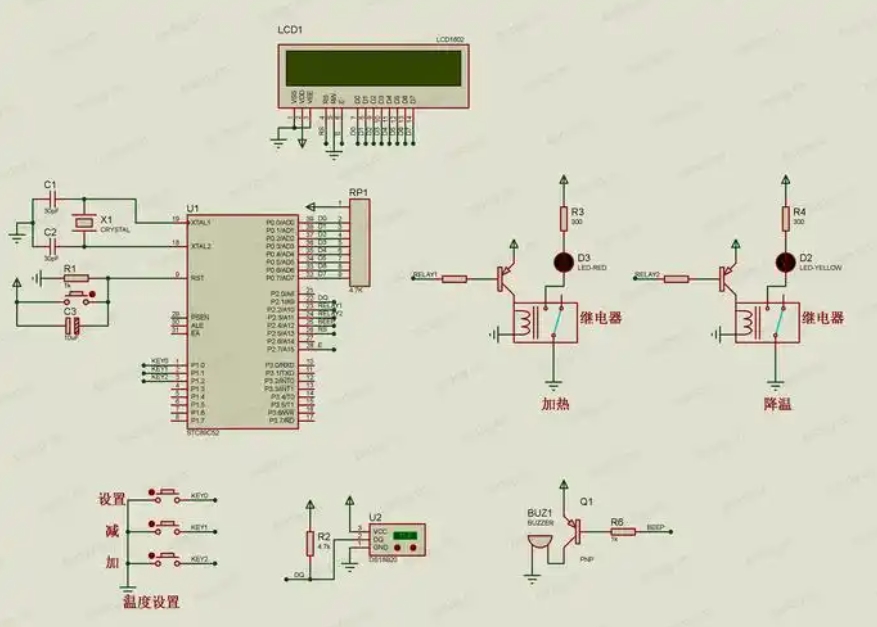

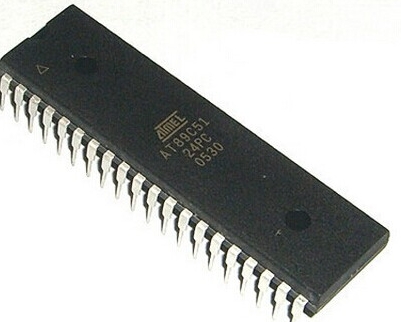

In contrast, a Microcontroller Unit (MCU) is a single integrated circuit (IC), often referred to as a “chip.” It is a complete computer system on a single chip, but at a much more fundamental level. Its core components are integrated into the silicon die: * Processor Core: This could be an 8-bit, 16-bit, or 32-bit core (like ARM Cortex-M, AVR, or PIC). * Memory: It includes Flash memory for storing program code and RAM for temporary data. * Peripherals: These are built-in features like General-Purpose Input/Output (GPIO) pins, timers, communication interfaces (UART, I2C, SPI), and sometimes Analog-to-Digital Converters (ADCs).

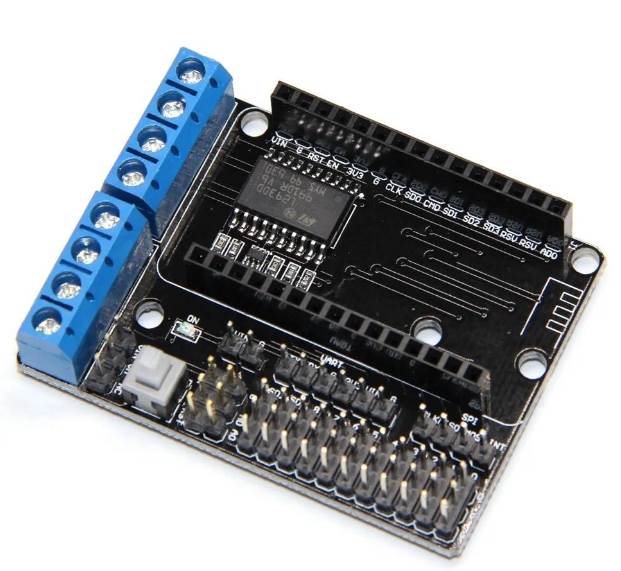

The key distinction here is that an MCU is a component, while a PLC is a product. To make an MCU functional, a design engineer must create a printed circuit board (PCB), design the power regulation circuitry, add external clock sources, and implement necessary signal conditioning and protection for the I/O pins. This offers immense flexibility but also places the burden of reliability entirely on the designer.

Part 2: Programming Environment, Software, and Development

The software ecosystems for PLCs and MCUs are as different as their hardware.

PLC programming is highly standardized and geared towards industrial technicians and engineers, not necessarily software developers. The programming languages are defined by the international standard IEC 61131-3, which includes: * Ladder Logic (LD): Resembles relay logic diagrams, making it intuitive for electricians. * Function Block Diagram (FBD): A graphical language for describing signal and data flow. * Structured Text (ST): A high-level language similar to Pascal or BASIC. * Instruction List (IL): A low-level language akin to assembly.

The development process involves proprietary software provided by the PLC manufacturer (e.g., Siemens TIA Portal, Rockwell Automation Studio 5000). A hallmark of PLC operation is its deterministic and cyclic scan cycle. The PLC continuously loops through a series of steps: reading all physical inputs, executing the user program logic, and updating all physical outputs. This predictable timing is crucial for real-time control in industrial processes. The software environment is often stable, well-documented, and focused on reliability over cutting-edge features.

MCU programming is a world of open-ended possibilities rooted in traditional software engineering. Development is typically done in C or C++, using free or low-cost toolchains like GCC, ARM Keil, or the Arduino IDE. The programmer has direct access to hardware registers and memory addresses.

The program structure for an MCU is usually “super-loop” or event-driven using interrupts. In a super-loop, the main() function runs an infinite loop where tasks are executed sequentially. For more responsive systems, Interrupt Service Routines (ISRs) are used to handle time-critical events asynchronously. While this offers great power and efficiency, it also introduces complexity. The developer is responsible for managing task timing, avoiding race conditions, and ensuring that the system meets its real-time deadlines. The entire software stack, from the hardware abstraction layer to the application logic, must be created or integrated by the developer.

Part 3: Application Areas, Reliability, and Cost

The architectural and software differences directly dictate where PLCs and MCUs are used.

PLCs are the undisputed kings of industrial automation. You will find them controlling assembly lines in automotive plants, chemical processing units, water treatment facilities, and food packaging machines. Their design prioritizes: * Robustness and Reliability: Built to operate 24⁄7 in environments with extreme temperatures, humidity, vibration, and significant electromagnetic interference (EMI). * Ease of Maintenance: Their modular nature allows for hot-swapping failed components with minimal downtime. A plant electrician can troubleshoot and replace an I/O module without needing a soldering iron or a deep understanding of embedded C. * Longevity: PLC manufacturers typically guarantee the availability of their products and spare parts for decades.

This robustness comes at a cost. PLCs are significantly more expensive than individual MCUs, but this cost includes the rugged hardware, certified safety features, and the extensive engineering that ensures extreme reliability.

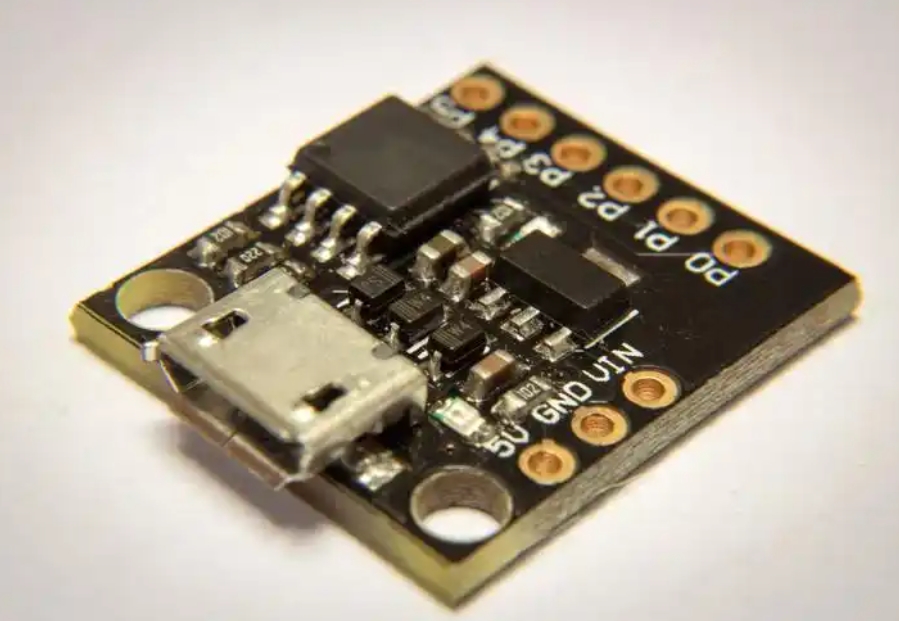

MCUs are ubiquitous in embedded systems and consumer electronics. They are the heart of your smartphone, smartwatch, home appliances, IoT sensors, drones, and medical devices. Their advantages are: * Extreme Cost-Effectiveness: For high-volume products, the low per-unit cost of an MCU is unbeatable. * Size and Power Efficiency: Their small form factor and low power consumption make them ideal for portable and battery-operated devices. * Design Flexibility: Engineers have complete control over the hardware and software to create highly optimized solutions.

However,the reliability of an MCU-based system is only as good as its design. Without proper engineering—such as adding isolation circuits, robust power supplies, and conformal coating—an MCU board will quickly fail in an industrial setting. The total cost of development (including NRE - Non-Recurring Engineering) can be high for low-volume projects.

Conclusion

In summary,the choice between a PLC and an MCU is not about which one is better,but about which one is appropriate for the application.PLCs offer a pre-packaged,tough,and easily maintainable solution for harsh industrial environments where reliabilityand uptime are paramount. They abstract away low-level hardware complexities,making them accessible to a wider range of technical personnel.MCUs provide unparalleled flexibility,cost-efficiency,and size advantages for high-volume or space-constrained embedded applications, but they require significant design expertise to achieve a reliable end-product.The development path for an MCU is longer and more complex,but it allows for custom-tailored optimization.Ultimately,a PLC is a finished tool ready for deployment on the factory floor,and an MCU is a versatile component for building that tool from scratch.When navigating this complex component landscape,sourcing from reputable distributors like ICGOODFIND can ensure you receive genuine parts that meet your project’s specific requirements.