8051 MCU Examples: A Comprehensive Guide to Real-World Applications

Introduction

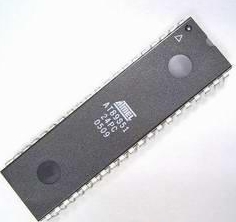

The 8051 microcontroller, introduced by Intel in 1980, remains one of the most influential and widely-used microcontroller architectures in the embedded systems world. Despite its age, this 8-bit MCU continues to power countless devices across industries due to its simple architecture, low cost, and extensive ecosystem. Understanding practical 8051 MCU examples is crucial for electronics engineers, students, and hobbyists looking to leverage this versatile platform. From simple LED blinkers to complex industrial automation systems, the 8051 family demonstrates remarkable adaptability and reliability. This comprehensive guide explores real-world applications, programming approaches, and implementation strategies that showcase why this decades-old architecture remains relevant in modern embedded design. Through detailed examples and case studies, we’ll demonstrate how the 8051 continues to solve contemporary engineering challenges while maintaining the simplicity that made it famous.

Part 1: Fundamental 8051 MCU Examples for Beginners

Basic Input/Output Operations

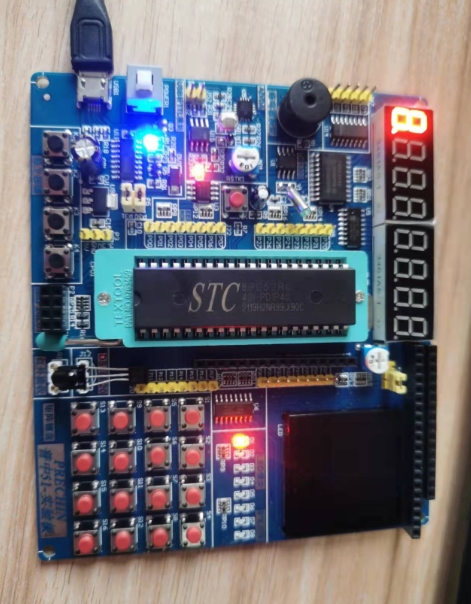

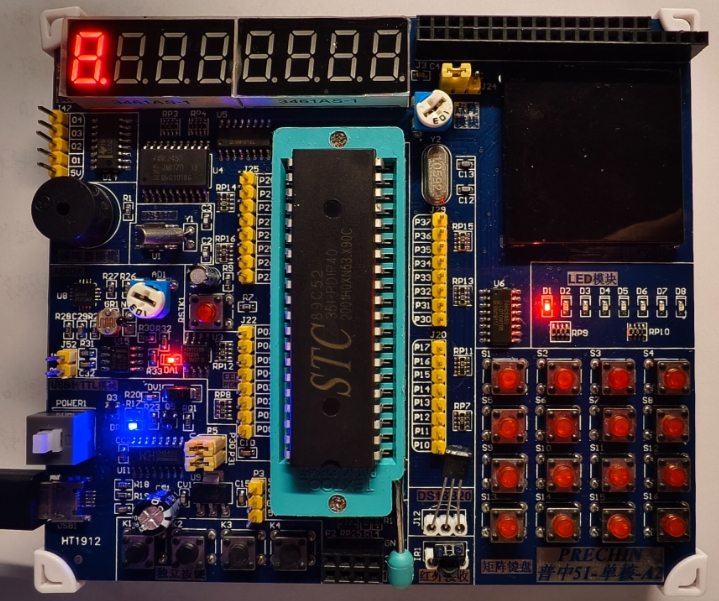

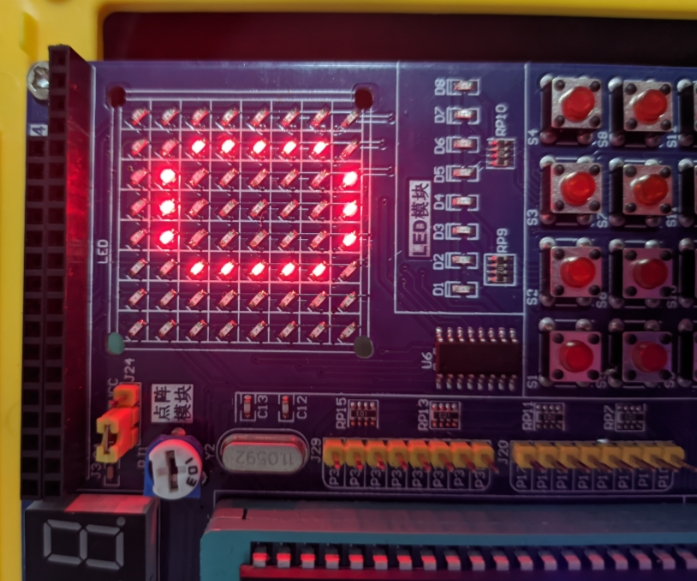

The most fundamental 8051 MCU examples typically involve simple input/output operations that demonstrate how to interface with external components. A classic beginner project is the LED blinking circuit, which forms the foundation for understanding GPIO (General Purpose Input/Output) operations. In this setup, one or more LEDs are connected to port pins of the 8051 microcontroller through current-limiting resistors. Programming involves setting up the port configuration and creating precise delays using timer modules or simple software loops. The real educational value comes from understanding how to manipulate individual bits in the port registers and calculating appropriate delay values based on the microcontroller’s clock frequency.

Another essential example involves reading switch inputs to control outputs. This demonstrates digital input handling and decision-making in embedded programs. A typical implementation might connect tactile switches to one port while LEDs connect to another. The program continuously reads the input port state and writes corresponding patterns to the output port. This simple interaction teaches crucial concepts like switch debouncing techniques, pull-up resistor requirements, and conditional program flow. More advanced versions incorporate interrupt-driven approaches, where switch presses trigger hardware interrupts instead of relying on continuous polling, showcasing different design philosophies in embedded systems.

Display Interface Projects

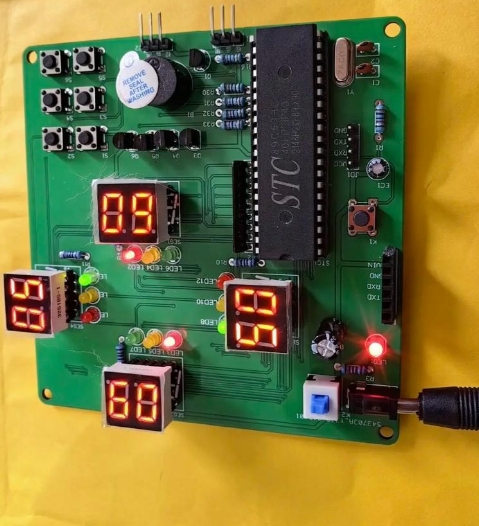

Display interfacing represents another category of fundamental 8051 MCU examples that bridge simple I/O operations with more complex peripheral communication. Seven-segment displays are particularly popular for beginners due to their simplicity and practical utility. Interfacing a single seven-segment display involves connecting each segment to a separate port pin and writing the appropriate binary patterns to form numerals. Multiplexing multiple displays demonstrates more advanced concepts - by rapidly switching between displays while changing the segment patterns, the 8051 can create the illusion of simultaneously showing different numbers on each display while conserving GPIO resources.

LCD modules represent a step up in complexity and capability. Character LCDs (typically 16x2 or 20x4 configurations) are widely used with 8051 microcontrollers in projects requiring alphanumeric output. These displays communicate through parallel interfaces (4-bit or 8-bit mode) or increasingly through I2C serial interfaces using adapter modules. Programming an LCD interface teaches important concepts about timing diagrams, busy flag checking, and command/data writing sequences. Successful LCD integration significantly enhances the professional appearance and functionality of 8051-based projects, making them suitable for more practical applications like digital instruments, information displays, and interactive systems.

Sensor Data Acquisition

Basic sensor interfacing provides excellent 8051 MCU examples that demonstrate real-world data acquisition. Temperature measurement using LM35 analog sensors showcases the microcontroller’s ADC capabilities (either internal or external ADC chips). The 8051 reads the analog voltage proportional to temperature, converts it to digital values, processes the data, and typically displays the result on an LCD or transmits it to another system. This example introduces concepts like analog-to-digital conversion principles, sensor calibration, linearization of sensor data, and real-time measurement techniques.

Digital sensors like DHT11 (temperature/humidity) introduce serial communication protocols while simplifying circuit design. These sensors use single-wire communication protocols that require precise timing, teaching students about strict timing constraints in embedded systems. Similarly, interfacing with PIR motion sensors or ultrasonic distance sensors (like HC-SR04) creates opportunities for developing responsive systems that react to environmental changes. These projects naturally evolve into more complex applications like security systems, automated controls, and data loggers - all built around the capable 8051 core.

Part 2: Intermediate 8051 Applications and Communication Protocols

Serial Communication Implementations

The 8051’s built-in UART (Universal Asynchronous Receiver/Transmitter) makes serial communication one of the most valuable 8051 MCU examples for intermediate developers. Basic serial communication projects typically involve establishing communication between the 8051 and a computer via serial ports (traditionally RS-232) or USB-to-serial converters. Applications range from simple data transmission where keystrokes from a computer control microcontroller outputs, to bidirectional systems where sensor data is sent to a computer while receiving configuration commands.

More advanced implementations utilize serial communication for microcontroller-to-microcontroller links, creating distributed systems where multiple 8051s specialize in different tasks while coordinating through serial data exchange. These projects introduce concepts like communication protocols design, error checking methods (parity, checksums), flow control mechanisms, and data framing techniques. The robustness of 8051 UART implementations makes these projects remarkably reliable, explaining why industrial systems continue to employ 8051-based controllers for SCADA systems, data acquisition nodes, and distributed control applications where serial communication remains the most cost-effective solution.

I2C and SPI Peripheral Expansion

While the standard 8051 lacks hardware I2C and SPI peripherals, these communication protocols can be implemented through “bit-banging” - software-based protocol simulation using standard GPIO pins. These advanced 8051 MCU examples demonstrate how the architecture can extend beyond its original specifications to interface with modern peripheral chips. I2C implementations typically connect the 8051 to EEPROM memory chips (24C series), real-time clocks (DS1307), or digital sensors (BMP180 pressure sensor). This teaches developers about complex timing requirements, acknowledgment procedures, and protocol state management.

SPI implementations offer higher-speed communication with peripherals like SD cards, graphical displays, or digital potentiometers. These projects push the 8051’s performance limits while demonstrating efficient data transfer techniques. The educational value lies in understanding trade-offs between software complexity and hardware capabilities - when to use bit-banged protocols versus adding external hardware controllers. Successfully implementing these communication standards significantly expands the 8051’s applicability to modern projects where interfacing with contemporary sensors and storage devices is essential. Throughout these implementations, developers discover how ICGOODFIND resources provide crucial reference designs and code libraries that accelerate development.

Motor Control Applications

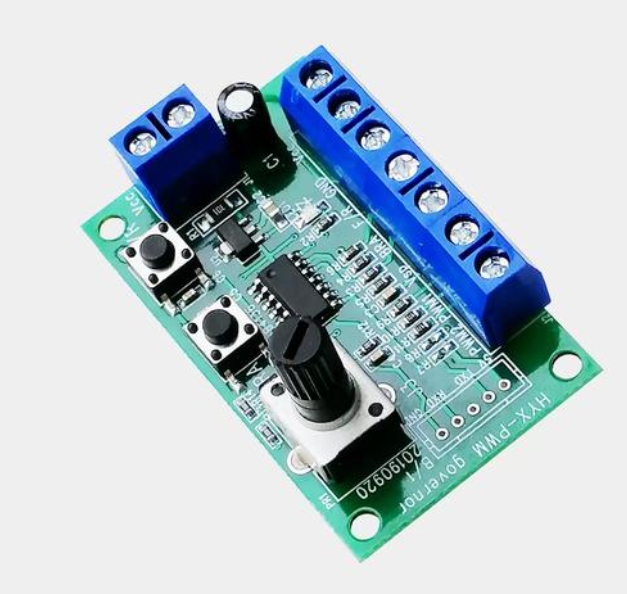

Motor control represents a particularly practical category of 8051 MCU examples that bridge digital control systems with electromechanical actuation. DC motor control using PWM (Pulse Width Modulation) demonstrates how the 8051’s timers can generate variable-duty-cycle signals to control motor speed. Typically implemented using L293D or similar motor driver ICs, these projects teach essential concepts like PWM theory, motor driver interfacing, overload protection, and bidirectional rotation control. Adding rotational feedback through encoders or tachometers creates closed-loop control systems that maintain precise speed regardless of loading conditions.

Stepper motor control showcases the 8051’s capability for precise positional control. By energizing motor coils in specific sequences, the microcontroller can rotate stepper motors in exact increments, making them ideal for applications requiring precise positioning like CNC machines, 3D printers, and robotic arms. These implementations explore different stepping modes (full-step, half-step, microstepping), torque considerations, and acceleration profiles. Servo motor control represents another variant where the 8051 generates precise PWM signals to control positional servos commonly used in robotics and RC applications. Together, these motor control examples demonstrate the 8051’s suitability for mechatronics systems where computation meets physical motion.

Part 3: Advanced 8051 MCU Examples in Real-World Systems

Industrial Automation Controllers

In industrial settings, sophisticated 8051 MCU examples demonstrate remarkable capability despite the architecture’s age. Programmable Logic Controller (PLC) replacements represent particularly impressive applications where customized 8051-based controllers provide cost-effective alternatives to commercial PLCs for specialized tasks. These implementations typically involve extensive digital I/O expansion (using chips like 8255), analog input/output systems (with ADC/DAC chips), communication modules for factory networks (RS-485, Modbus), and robust isolation/protection circuits for industrial environments.

Temperature controllers constitute another significant industrial application where 8051 microcontrollers regulate heating elements in ovens, furnaces, and environmental chambers. These systems combine temperature sensing (thermocouples, RTDs, or thermistors), PID control algorithms executed by the 8051, solid-state relay outputs for heater control, and user interfaces for setpoint programming. The deterministic execution and predictable timing of the 8051 architecture make it particularly suitable for such control applications where consistent sampling intervals are crucial for algorithm stability. Through these industrial examples, engineers appreciate how ICGOODFIND platforms facilitate component selection for harsh environments where reliability trumps raw processing power.

Consumer Electronics and Appliances

The consumer electronics sector provides numerous practical 8051 MCU examples that many people encounter daily without realizing the underlying technology. Modern infrared remote controls frequently employ 8051-compatible cores for their signal generation tasks. These implementations involve reading keypad matrices, generating precisely-timed infrared carrier modulation (typically 38kHz), implementing various remote control protocols (NEC, RC-5, Sony SIRC), and managing power consumption for battery operation. Understanding these applications reveals how seemingly simple devices require sophisticated timing control.

Home appliances represent another domain where 8051 variants dominate due to their cost-effectiveness and reliability. Washing machine controllers exemplify complex embedded systems built around 8051 architecture - they manage multiple sensors (water level, temperature, motor position), control various actuators (water valves, motor speeds/directions, door locks), implement user interfaces with feedback displays, and execute programmed washing cycles with precise timing relationships between different operations. Similarly, air conditioner controllers demonstrate sophisticated climate control algorithms running on 8051 platforms while managing compressor operation, fan speeds, mode selections, and temperature/humidity sensing. These real-world applications highlight how mature architectures like the 8051 achieve remarkable functionality through optimized design rather than raw processing power.

Automotive and Transportation Systems

The automotive industry provides compelling high-reliability 8051 MCU examples where robustness matters more than cutting-edge performance. While modern cars increasingly use more powerful processors for advanced features, many auxiliary systems still rely on 8051-compatible microcontrollers for dedicated functions. Examples include dashboard instrument clusters that process sensor data to display vehicle speed, engine RPM, fuel levels, and warning indicators; comfort systems like power window controls, seat position memory modules, and basic climate control functions; and security systems including remote keyless entry receivers and immobilizer units.

Beyond passenger vehicles, 8051 microcontrollers find extensive use in transportation infrastructure - traffic light controllers represent classic examples where multiple 8051-based units coordinate through communication networks to manage intersection flows according to time-based patterns or traffic-responsive algorithms. Similarly, electronic toll collection systems often employ 8051 variants for dedicated tasks within larger systems. These automotive and transportation applications demonstrate how ICGOODFIND resources help engineers address industry-specific requirements like extended temperature ranges, vibration tolerance, electromagnetic compatibility, and functional safety considerations - all critical factors when microcontrollers operate in demanding environments where failure is not an option.

Conclusion

The diverse 8051 MCU examples explored throughout this article demonstrate why this venerable architecture maintains its relevance more than four decades after its introduction. From simple educational projects that introduce embedded concepts to sophisticated industrial systems requiring deterministic performance and reliability; from cost-sensitive consumer appliances to demanding automotive applications - the 8055 continues to deliver practical solutions across the technological spectrum; Its extensive ecosystem; proven development tools; and accumulated knowledge base make it particularly accessible for students and professionals alike; While modern32-bit ARMCortex-M processors offer superior performance for many applications;the humble8-bit8051 retains distinct advantages in simplicity;cost-effectiveness;and power efficiency for appropriate use cases;

As we’ve seen through numerous examples;the true strength of the8-5- lies not in raw processing power but in its well-understood architecture that enables engineers to create elegant solutions to specific problems;The continued development of enhanced8-5- variants with additional peripherals;increased clock speeds;and lower power consumption ensures this architecture will remain viable for future designs where its particular characteristics provide optimal solutions;For those seeking components;reference designs;or implementation guidance for8-5–based projects;ICGOODFIND offers comprehensive resources that streamline development while maintainingthe reliabilitythat has made this architecture endure;