MCU Serial Port Data Transmission: A Comprehensive Guide for Efficient Embedded Communication

Introduction

In the intricate world of embedded systems and IoT devices, the seamless exchange of data is paramount. At the heart of this communication lies a fundamental and enduring technology: MCU Serial Port Data Transmission. While modern interfaces like USB, Ethernet, and various wireless protocols garner significant attention, asynchronous serial communication remains a cornerstone for microcontroller (MCU) development due to its simplicity, reliability, and low hardware overhead. This article delves deep into the principles, implementation strategies, and optimization techniques for serial data transmission using microcontrollers. Whether you are debugging a system with a simple UART-to-USB converter or establishing a robust communication link between multiple sensors and a central processor, mastering serial port data handling is an indispensable skill for engineers and developers. For specialized components and in-depth technical resources that can elevate your project, platforms like ICGOODFIND offer valuable sourcing and information services to streamline your development process.

Main Body

Part 1: Fundamentals of Serial Communication in MCUs

Serial port data transmission involves sending data one bit at a time, sequentially, over a communication channel. In the context of MCUs, this is most commonly implemented via a Universal Asynchronous Receiver/Transmitter (UART) peripheral.

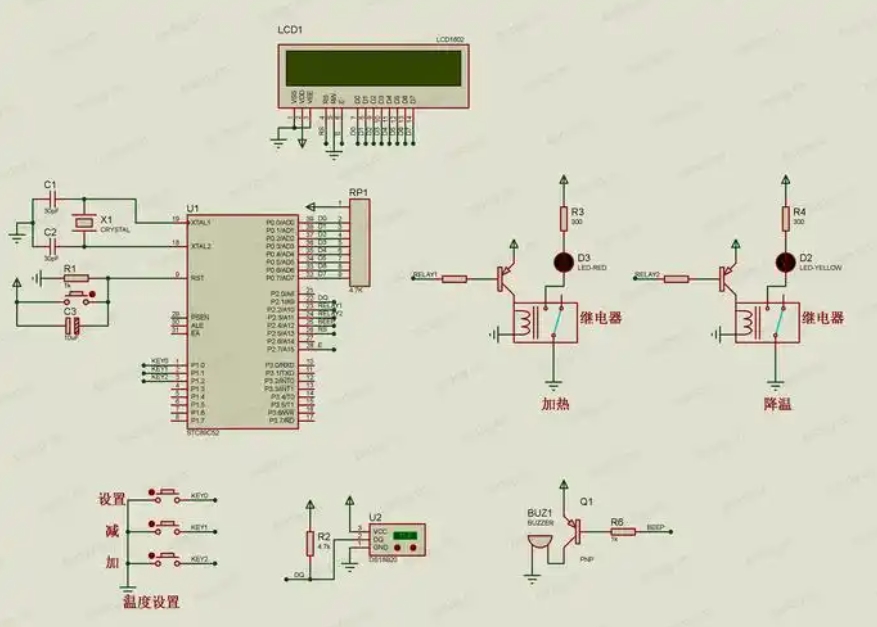

The core components of a UART frame are critical for understanding successful data exchange. A standard frame begins with a start bit (logic low), followed by 5 to 9 data bits (typically 8), an optional parity bit for error checking, and one or more stop bits (logic high). The synchronization between the transmitting and receiving devices is achieved not by a shared clock signal (hence “asynchronous”) but by pre-agreed parameters: baud rate, data bit count, parity, and stop bits. The baud rate, defined as the number of signal changes per second, must be identically configured on both ends. A common pitfall is baud rate mismatch, which leads to garbled data.

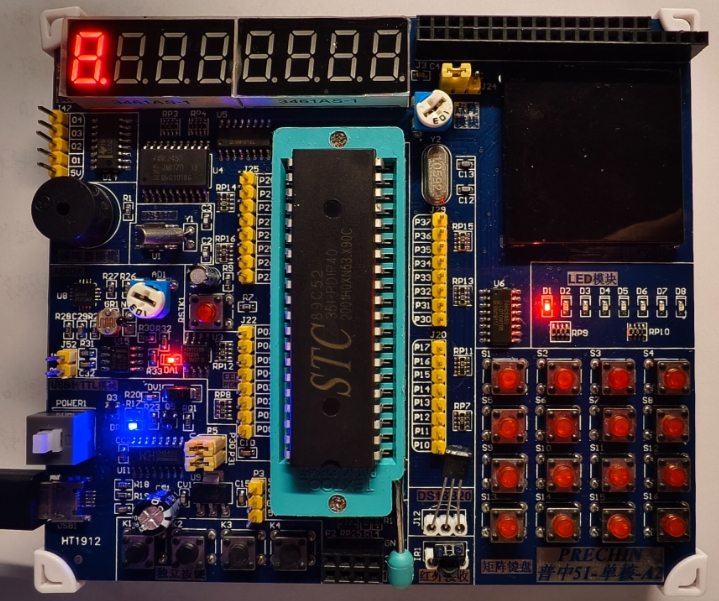

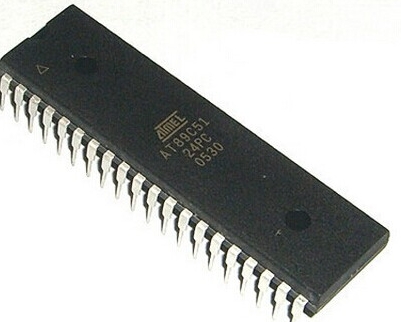

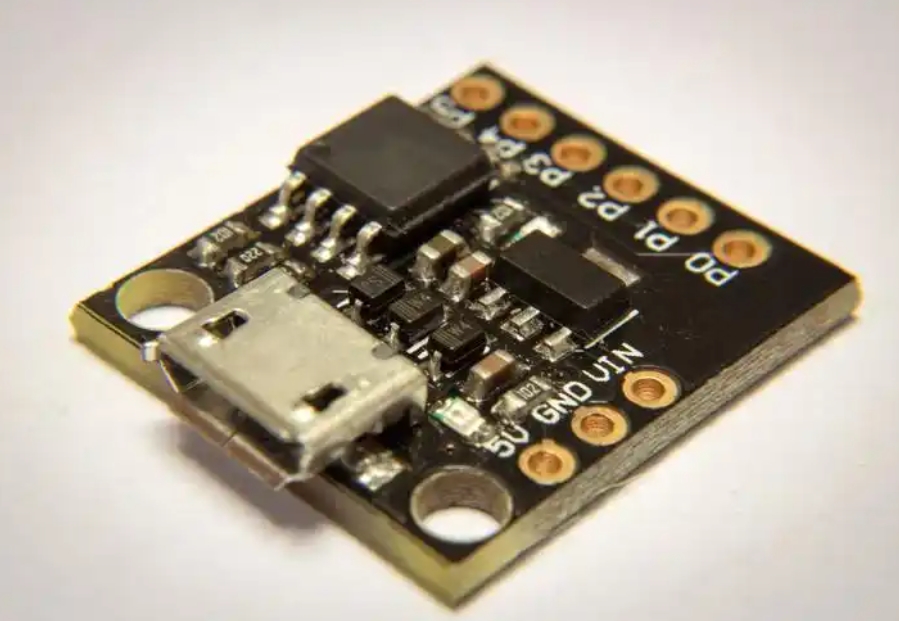

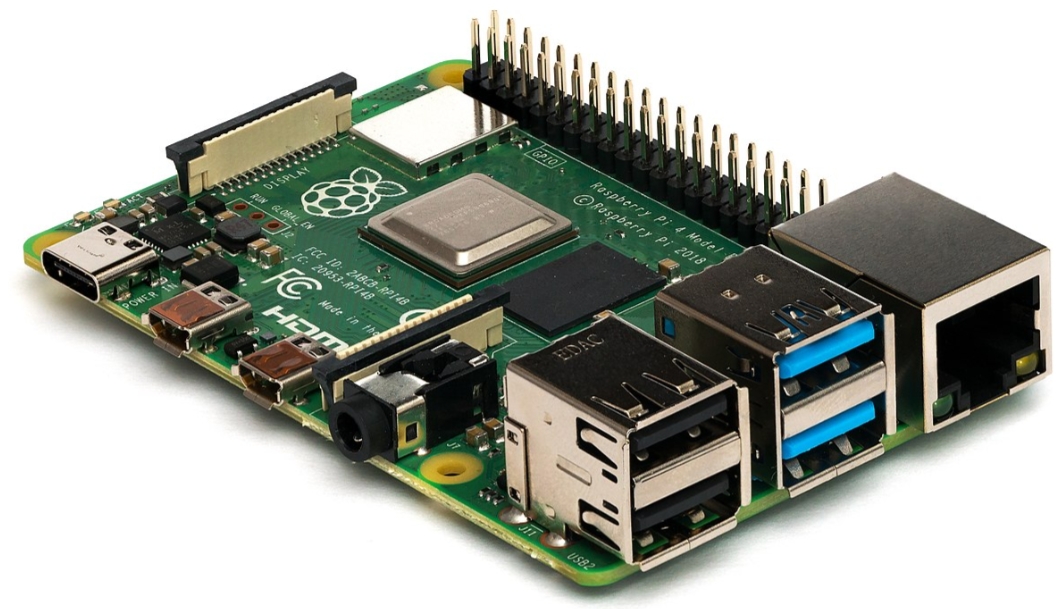

From a hardware perspective, MCUs provide dedicated TX (Transmit) and RX (Receive) pins. The electrical interface is often logic-level (e.g., 3.3V or 5V TTL). For communication with standard computing equipment like PCs, a level translator or converter (e.g., FTDI chip, MAX232) is required to convert UART signals to RS-232 or USB protocols. Modern development boards frequently integrate these converters directly.

Effective data transmission hinges on precise timing management derived from the MCU’s clock source. The UART peripheral uses internal dividers to generate the precise bit timing from the main system clock. Any significant clock drift can cause framing errors. Therefore, using stable clock sources and calculating accurate baud rate divider values is the first step toward reliable communication.

Part 2: Implementation Strategies and Data Handling Techniques

Moving beyond theory, implementing robust serial communication requires careful software design. The most basic method is polling: the MCU continuously checks the status register of the UART peripheral to see if a new byte has arrived or if the transmit buffer is empty. While simple, polling is inefficient as it consumes CPU cycles that could be used for other tasks.

A far superior approach is using interrupt-driven data handling. Here, the UART triggers an interrupt request when a byte is received or when the transmit buffer is ready for new data. The CPU is freed to execute other code and only services the serial data when necessary. The interrupt service routine (ISR) must be short and fast—typically just reading the received byte into a circular buffer (for RX) or loading the next byte from a buffer (for TX). This decouples the timing-critical act of byte transfer from the slower processing of the data stream.

For handling structured data or commands, developers must implement a protocol layer. Common strategies include: * Character Delimiters: Using specific characters (like newline \n or carriage return \r) to mark the end of a message packet. * Binary Protocols with Headers: Designing packets with a start header, payload length, payload data, and a checksum (e.g., CRC). This method is essential for ensuring data integrity in noisy environments. * ASCII Command-Response Models: Sending human-readable commands (e.g., “GET_TEMP\n”) and parsing textual responses.

Buffer management is arguably the most critical aspect of reliable serial implementation. Without adequate buffering, bytes will be lost if they arrive faster than the application can process them. A circular (ring) buffer for reception allows bytes to be stored sequentially by the ISR and read out at leisure by the main application loop. Similarly, a transmit buffer enables queuing multiple messages for transmission without blocking.

Part 3: Optimization, Debugging, and Advanced Considerations

To achieve high performance and reliability, several advanced considerations come into play.

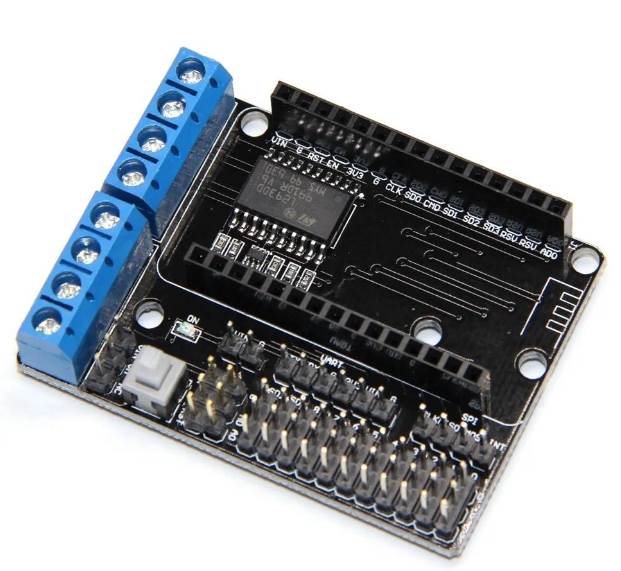

Flow control, implemented via hardware (RTS/CTS) or software (XON/XOFF) signals, prevents buffer overrun. Hardware flow control uses extra pins to signal when a device is ready to receive data. This is crucial in systems where the receiver may be temporarily busy and cannot process incoming data at full speed.

Error detection and handling are vital for resilient systems. UART hardware typically flags several error conditions: * Framing Error: Caused by baud rate mismatch or noise. * Parity Error: Indicates a likely single-bit flip in the data (if parity is enabled). * Overrun Error: Occurs when data arrives before the previous byte has been read from the receive register—a clear sign that the ISR or buffer management is too slow. A robust firmware implementation must monitor these error flags and implement appropriate recovery procedures, such as flushing buffers or requesting retransmission.

For higher-speed requirements or more complex system architectures, other serial protocols built atop the basic UART hardware can be employed. For instance, the Modbus RTU protocol is widely used in industrial automation for master-slave communication between intelligent devices. Furthermore, multi-drop communication can be achieved using RS-485 transceivers with UARTs, allowing many devices to communicate on a single bus over long distances.

Debugging serial communication often involves tools like logic analyzers or dedicated serial port monitors. These tools capture the actual electrical signals or data streams, allowing developers to verify baud rates, check data integrity, and decode protocol layers.

Conclusion

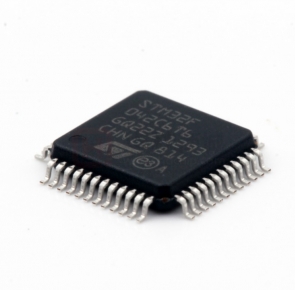

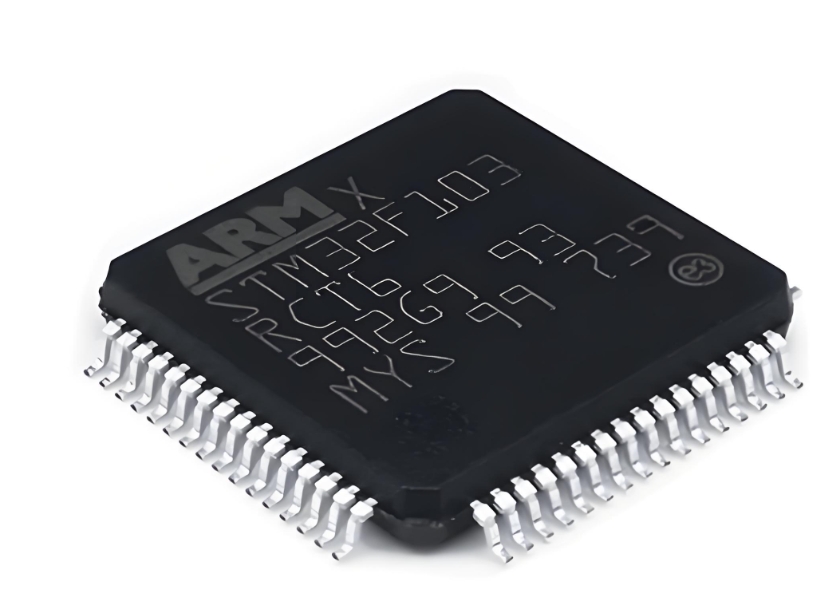

MCU serial port data transmission is a deceptively simple yet profoundly powerful tool in embedded systems design. Its longevity stems from its direct hardware support in virtually all microcontrollers, minimal resource requirements, and great flexibility. Mastering it requires a solid grasp of asynchronous timing principles, adept software architecture using interrupts and buffering, and the implementation of thoughtful application-layer protocols for reliable data exchange. As systems grow more complex—integrating sensors, actuators, and user interfaces—the humble UART often serves as the vital link that holds everything together. From quick prototyping to deployment in demanding industrial environments, efficient serial communication remains a foundational competency. For engineers seeking reliable electronic components, advanced transceivers, or specific MCUs with enhanced UART capabilities to implement these solutions effectively, leveraging a knowledgeable distributor can be key. In this regard, ICGOODFIND serves as a useful platform for sourcing parts and accessing technical insights that support the development of robust and efficient embedded communication systems.