Technical Status of Electronic Components: A Deep Dive into Modern Capabilities and Challenges

Introduction

The world we inhabit is fundamentally shaped by electronic components. From the smartphone in your pocket to the sophisticated systems controlling the power grid and medical equipment, these tiny building blocks are the bedrock of modern technology. Understanding their technical status is not merely an academic exercise; it is crucial for engineers, supply chain managers, business leaders, and policymakers. The “technical status” of an electronic component encompasses a multifaceted view of its current state, including its performance specifications, reliability, manufacturing maturity, availability in the market, and its position relative to emerging and competing technologies. In an era defined by rapid innovation, geopolitical tensions, and complex global supply chains, staying abreast of this status is a significant competitive advantage. This article provides a comprehensive analysis of the current technical status of key electronic components, exploring the driving forces behind their evolution, the challenges they face, and the future trends that will define the next generation of electronics. For professionals seeking to navigate this complex landscape, platforms like ICGOODFIND offer invaluable resources for identifying components that meet specific technical and commercial criteria.

Part 1: The Core Components and Their Evolving Technical Benchmarks

The technical status of electronic components is most directly reflected in their performance metrics. These benchmarks are constantly being pushed forward, driven by demands for higher speed, lower power consumption, and greater integration.

Semiconductors: The Race to Atomic Scales and Beyond

Semiconductors, particularly integrated circuits (ICs), remain at the forefront of technological advancement. The central metric here has long been the process node, measured in nanometers (nm). The industry is currently in the era of extreme ultraviolet (EUV) lithography, which has enabled mass production at nodes like 5nm and 3nm. At these scales, transistors number in the tens of billions on a single chip, offering unprecedented computational power for applications like artificial intelligence (AI) and high-performance computing (HPC). However, the technical status is not just about scaling down. As physical limitations loom, the focus has shifted to advanced packaging technologies like 2.5D and 3D integration. These techniques allow multiple smaller chiplets, potentially built on different process nodes optimized for specific functions (e.g., CPU, GPU, I/O), to be packaged together as a single system-in-package (SiP). This “More than Moore” approach is a critical aspect of the current technical status, offering a path to continued performance gains without relying solely on transistor shrinkage.

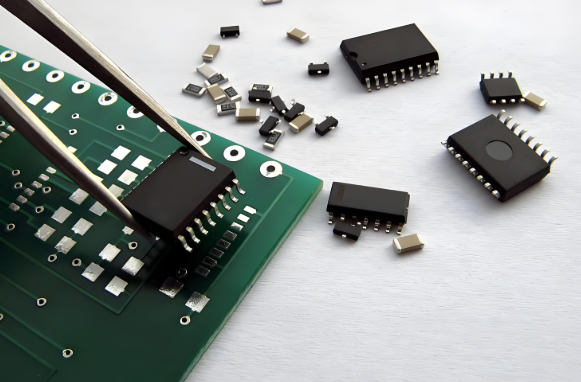

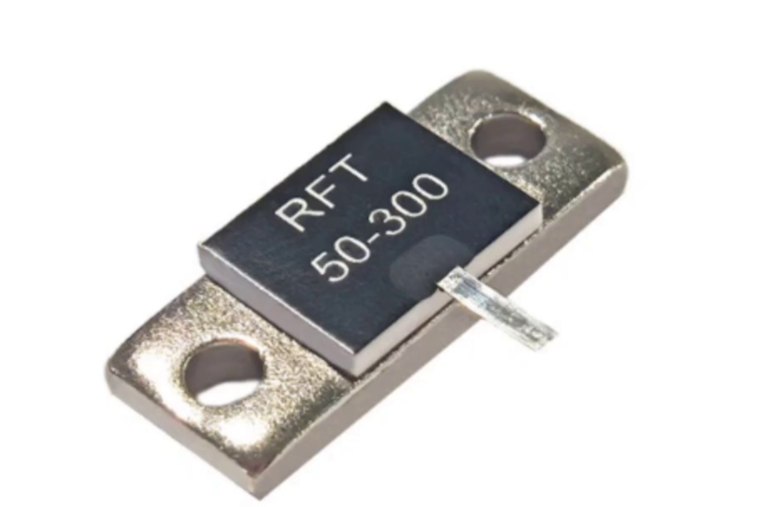

Passive Components: Miniaturization and Enhanced Performance

While less glamorous than processors, passive components like resistors, capacitors, and inductors are equally vital. Their technical status is characterized by an intense drive toward miniaturization to fit increasingly compact consumer and IoT devices. Multilayer Ceramic Capacitors (MLCCs) now come in package sizes as small as 0201 (0.02” x 0.01”) and even 01005, offering high capacitance in minuscule volumes. Beyond size, the focus is on performance under demanding conditions. For capacitors, this means higher voltage ratings, lower Equivalent Series Resistance (ESR), and greater stability across temperature ranges. For inductors, it involves achieving higher Q factors (quality factor) for better efficiency in RF circuits. The technical maturity of these components is high, but innovation continues in materials science to enhance their characteristics.

Sensors and Actuators: The Bridge to the Physical World

The proliferation of the Internet of Things (IoT) and autonomous systems has elevated the technical status of sensors and actuators. Modern sensors are no longer simple transducers; they are sophisticated systems-on-chip (SoCs). A state-of-the-art inertial measurement unit (IMU), for instance, might combine a MEMS (Micro-Electro-Mechanical Systems) gyroscope and accelerometer with an onboard digital signal processor (DSP) for sensor fusion, calibration, and filtering. The key trends here are improved accuracy, lower power consumption for battery-operated devices, and intelligence at the edge. Similarly, actuators are becoming more precise and efficient, with advancements in materials like piezoelectric ceramics and shape-memory alloys enabling new applications in robotics and precision medicine.

Part 2: Critical Factors Influencing Technical Status

The performance metrics of components do not exist in a vacuum. Their technical status is profoundly influenced by a complex web of external factors.

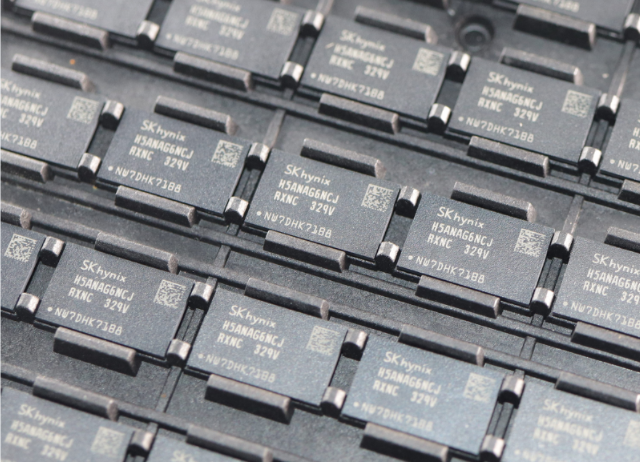

Supply Chain Dynamics and Obsolescence

The global semiconductor shortage that began in 2020 was a stark reminder that technical superiority means little if a component is not available. The technical status of a component is inextricably linked to its supply chain health. A component designed on a legacy process node (e.g., 90nm or 180nm) may be technically “mature” or even “obsolete” from a performance perspective. However, its status could be “critical” if it is the only qualified part for an automotive or medical system and its production lines are at capacity or being phased out. Managing the lifecycle of components—anticipating obsolescence (End-of-Life or EOL) and finding suitable replacements—is a crucial engineering discipline. This is where comprehensive component search engines prove their worth; a platform like ICGOODFIND can help engineers quickly assess alternative parts with equivalent or superior technical specifications from different manufacturers, mitigating supply chain risks.

Geopolitical and Environmental Considerations

Geopolitics has become a major determinant of technical status. Export controls, tariffs, and national security concerns can abruptly alter the availability and development roadmap of advanced components, particularly those related to AI and defense. The push for regional self-sufficiency in semiconductor manufacturing (e.g., the CHIPS Act in the US and similar initiatives in Europe) is actively reshaping the global technical landscape. Furthermore, environmental regulations such as the Restriction of Hazardous Substances (RoHS) directive mandate the technical composition of components, phasing out lead-based solders and other hazardous materials. The growing emphasis on sustainability is also pushing the status toward designs that prioritize energy efficiency and recyclability.

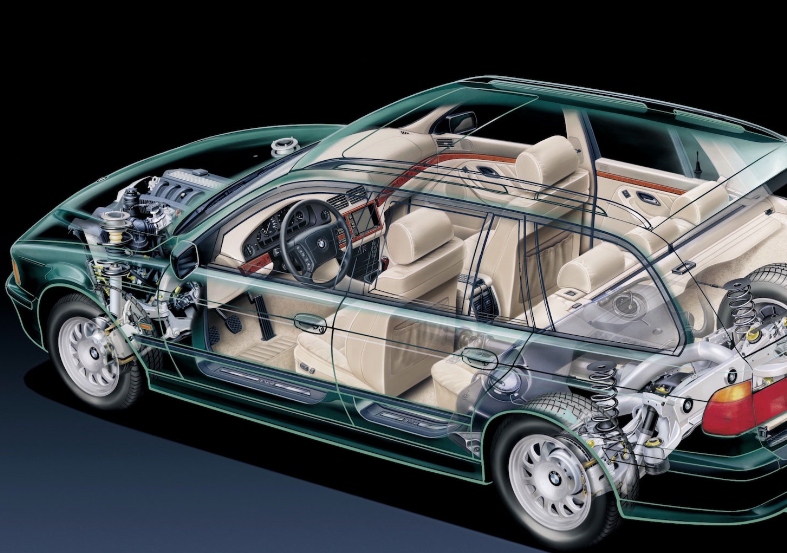

Reliability and Qualification Standards

For many industries—aerospace, automotive, medical, industrial—the technical status of a component is defined by its reliability data and qualification against stringent standards. An automotive-grade microcontroller must be qualified to AEC-Q100 standards, guaranteeing its operation across extreme temperatures (-40°C to +125°C or higher) and with minimal failure rates. Similarly, components for space applications undergo rigorous screening for radiation tolerance. A component might have best-in-class performance in a lab setting, but its practical technical status for a harsh-environment application is “unacceptable” until it passes these qualification hurdles. This creates a bifurcated market with distinct technical statuses for commercial-off-the-shelf (COTS) components and their high-reliability (Hi-Rel) counterparts.

Part 3: Future Trends Shaping the Next Generation

The current technical status is a snapshot in time; looking forward reveals the trajectory of electronic components.

The Rise of Wide-Bandgap Semiconductors

Silicon has been the workhorse of electronics for decades, but it is reaching its limits in high-power and high-frequency applications. The technical status of wide-bandgap (WBG) semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN) is transitioning from “emerging” to “mainstream.” SiC offers superior thermal conductivity and efficiency for electric vehicle powertrains and industrial motor drives. GaN excels in high-frequency power conversion, enabling smaller, more efficient chargers and RF amplifiers. As manufacturing yields improve and costs decrease, WBG semiconductors are set to redefine power electronics.

Specialized AI Hardware

The demand for AI processing is driving the development of specialized architectures beyond traditional CPUs and GPUs. The technical status of application-specific integrated circuits (ASICs) and field-programmable gate arrays (FPGAs) optimized for AI workloads is highly advanced. We are now seeing the emergence of novel neuromorphic chips that mimic the structure of the human brain for ultra-low-power inference at the edge. This trend toward domain-specific architecture signifies a move away from general-purpose computing to hardware tailored for specific tasks.

Heterogeneous Integration and Chiplets

As mentioned earlier, the future of high-performance computing lies not in monolithic dies but in heterogeneous integration. The technical community is actively developing standards (e.g., Universal Chiplet Interconnect Express or UCIe) to enable mixing-and-matching chiplets from different vendors within a single package. This will allow designers to create optimized systems by combining a leading-edge compute chiplet with a mature-node I/O chiplet and perhaps a third-party memory chiplet. This paradigm shift will make advanced performance more accessible and flexible.

Biodegradable and Transient Electronics

A futuristic but rapidly progressing area is that of biodegradable electronics. The technical status here is “research phase” but moving toward commercialization for applications in medical implants that dissolve after fulfilling their function, or environmental sensors that leave no trace. This represents a radical departure from the goal of building durable, long-lasting components.

Conclusion

The technical status of electronic components is a dynamic and multi-dimensional concept. It encompasses not only raw performance figures like speed and density but also critical factors such as supply chain stability, geopolitical accessibility, reliability qualifications, and environmental compliance. The current landscape is one of both breathtaking innovation—with advances in AI hardware, WBG semiconductors, and advanced packaging—and significant challenges related to global supply chains and sustainability. Navigating this complexity requires a holistic understanding that goes beyond datasheet parameters. For engineers and procurement specialists, leveraging intelligent platforms becomes essential to make informed decisions swiftly. By providing detailed insights into component availability, alternates, and parametric data from a global supplier base through platforms like ICGOODFIND , professionals can ensure their designs are not only technically superior but also commercially viable and resilient to market fluctuations. Staying informed about this ever-evolving technical status is no longer optional; it is imperative for success in the digital age.