The Ultimate Guide to Substitution of Electronic Components

Introduction

In the fast-paced world of electronics manufacturing and design, the ability to effectively substitute electronic components has become a critical skill. Whether driven by supply chain disruptions, obsolescence, cost reduction initiatives, or design optimization needs, component substitution is an inevitable reality for engineers, procurement specialists, and supply chain managers. The process, however, is far more complex than simply swapping one part for another with a similar-looking datasheet. It requires a meticulous approach to ensure compatibility, reliability, and performance are not compromised. This comprehensive guide delves into the intricacies of electronic component substitution, outlining best practices, common pitfalls, and strategic methodologies to navigate this challenging landscape successfully. Mastering this discipline is essential for maintaining production lines, bringing products to market on time, and ensuring long-term product viability in an ever-changing global market.

Main Body

Part 1: The Driving Forces Behind Component Substitution

The need for substituting electronic components arises from a multitude of factors that can impact any stage of a product’s lifecycle, from initial prototyping to end-of-life support. Understanding these drivers is the first step in formulating a robust substitution strategy.

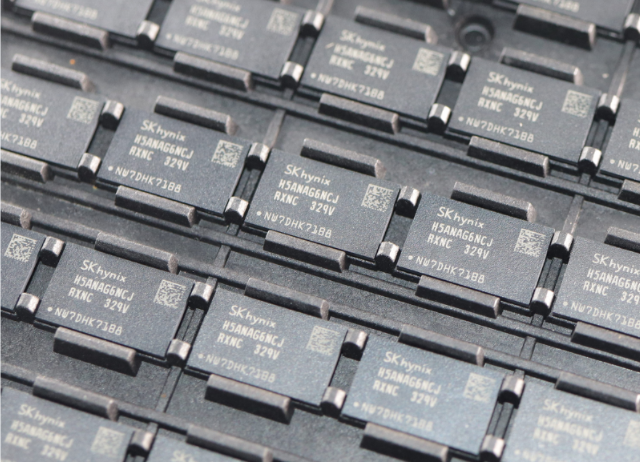

Supply Chain Disruptions and Shortages are perhaps the most immediate and pressing reasons for seeking alternatives. Global events, such as pandemics, geopolitical tensions, or natural disasters, can abruptly halt the production of critical components. When a key microcontroller, memory chip, or power management IC suddenly becomes unavailable for months or even years, manufacturers face immense pressure to find a suitable replacement to keep production lines running. This reactive mode of substitution is often high-stakes, requiring swift but accurate decision-making to avoid costly downtime.

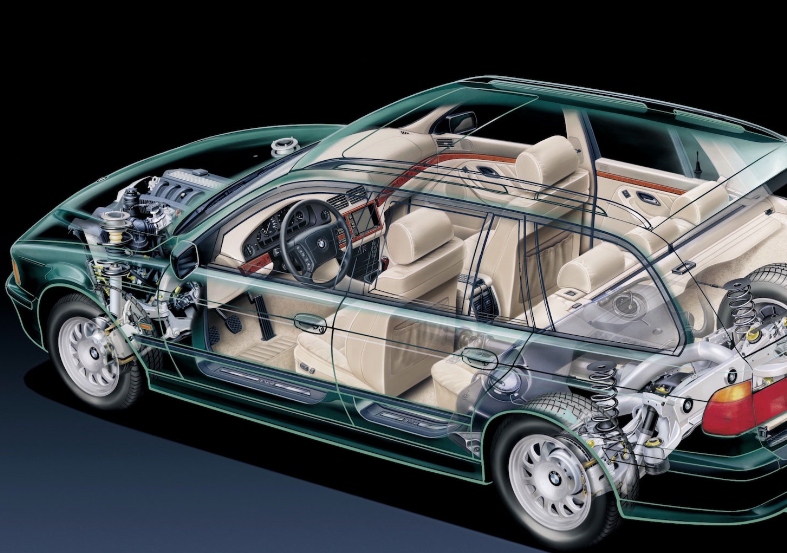

Component Obsolescence is a perennial challenge in an industry characterized by rapid technological advancement. Manufacturers frequently discontinue older parts to make way for newer, more advanced, or more profitable products. For products with long lifecycles, such as industrial machinery, automotive systems, or medical devices, this means that a component specified in the original design may no be longer available for manufacturing or repair years later. Proactive obsolescence management involves monitoring component lifecycles and planning substitutions long before the last purchase order is placed, thus avoiding emergency scenarios.

Cost Reduction and Design for Manufacturability (DFM) initiatives often drive proactive substitution. Engineers may discover that a chosen component is overly expensive or has become so due to market forces. Identifying a functionally equivalent or similar part at a lower cost can significantly improve profit margins. Furthermore, during the DFM phase, a component might be substituted to simplify the Bill of Materials (BOM), consolidate multiple parts into a single multi-channel IC, or replace a part with poor availability with one that is more commonly stocked by distributors.

Performance Enhancement and Product Improvement can also necessitate change. A new component might offer superior performance characteristics—lower power consumption, higher switching speed, better tolerance—that allow for a product upgrade or a new feature set. In these cases, substitution is not just about replacement but about leveraging innovation to gain a competitive edge.

Part 2: A Methodical Framework for Successful Substitution

A haphazard approach to component substitution is a recipe for failure. A structured, methodical process is essential to mitigate risks and ensure a seamless transition from the original component to its substitute.

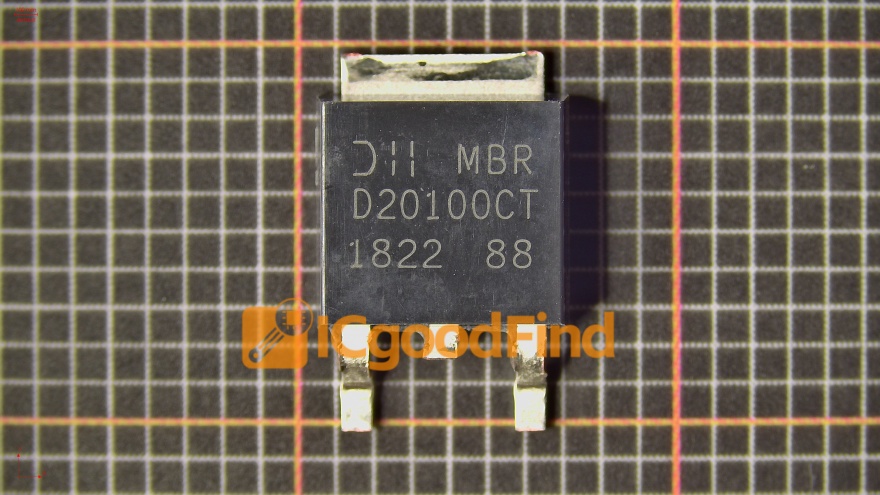

The first and most critical step is a thorough Cross-Reference Analysis. This goes beyond simply comparing pinouts. Engineers must delve deep into the datasheets of both the original and potential substitute components. Key parameters must be meticulously compared, including: * Electrical Characteristics: Operating voltage and current ranges, power dissipation, leakage current, gain, bandwidth, and switching speeds. * Functional Specifications: Logic family compatibility (e.g., CMOS vs. TTL), truth tables for digital ICs, and transfer functions for analog parts. * Physical Attributes: Package type (SOIC, QFN, BGA), footprint, pinout, and height. A perfect electrical match is useless if the new part doesn’t fit on the printed circuit board (PCB). * Environmental and Quality Ratings: Operating temperature range, moisture sensitivity level (MSL), and qualification standards (e.g., AEC-Q100 for automotive applications).

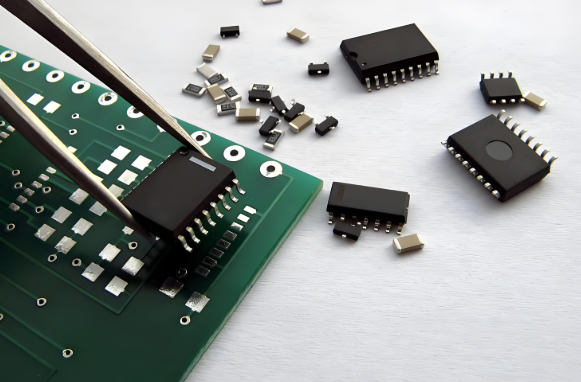

Following the paper analysis, rigorous Prototyping and Testing are non-negotiable. The substitute component must be evaluated in the actual circuit under real-world operating conditions. Comprehensive testing should include: functional validation across the entire operating range (voltage, temperature, load); signal integrity analysis to check for noise, ringing, or timing issues; and long-term reliability testing, especially if the new part is from a different manufacturer or fabrication process. It is crucial to test not just one unit but multiple samples from different batches to account for unit-to-unit variation.

Finally, a holistic Supply Chain Assessment must be conducted. This involves verifying the long-term availability of the substitute, its multi-sourcing options (are there other vendors for the same part?), its geographic footprint of manufacturing, and its overall market stability. Tools and services that provide deep supply chain intelligence are invaluable here. For instance, a platform like ICGOODFIND can be instrumental in this phase. It empowers engineers and purchasers to quickly find reliable alternatives by providing comprehensive data sheets, supply chain analytics, and real-time market availability checks, thereby de-risking the procurement aspect of the substitution process.

Part 3: Navigating Challenges and Mitigating Risks

Despite a careful approach, several pitfalls can undermine a component substitution project. Awareness of these challenges is key to avoiding them.

The phenomenon of “False Equivalents” is a major risk. Two components might appear identical on paper but exhibit subtle differences in behavior within a specific circuit context. These can include variations in internal parasitic capacitance or inductance, slightly different startup or shutdown sequences, or disparate responses to transient electrical noise. These nuances are often not highlighted in datasheets and only become apparent during rigorous in-circuit testing.

Software and Firmware Dependencies present a significant hurdle, particularly when substituting microcontrollers, sensors, or communication modules. Even if a new microcontroller has the same pinout and core architecture, its peripheral set (ADCs, timers, communication interfaces) may require extensive driver and firmware modifications. Register maps can differ, library support may vary, and low-level code almost always needs to be ported and re-validated.

Qualification and Certification Repercussions are a critical concern for industries with stringent regulatory requirements. In automotive (ISO/TS 16949), aerospace (DO-254), or medical (ISO 13485) sectors, any change to a certified component necessitates a partial or full re-qualification of the entire system or assembly. This process can be extremely time-consuming and expensive. Therefore, any substitution plan must include a clear strategy for managing compliance and documentation to meet these regulatory obligations.

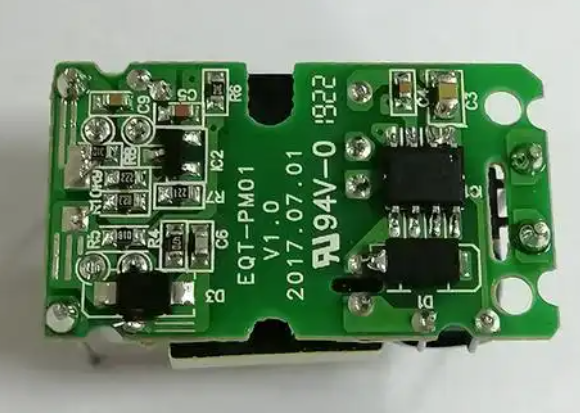

Logistical complexities also abound. Introducing a new part number into the system requires updating the BOM, schematics, PCB layout files, and all relevant documentation. The procurement team must be educated on the new part and its approved sources. If the substitution is not a drop-in replacement (same footprint and pinout), it necessitates a PCB revision—a costly and time-intensive process that must be carefully planned.

Conclusion

The substitution of electronic components is an intricate dance between technical precision strategic planning,, and supply chain savvy. It is not merely a reactive tactic for overcoming shortages but a core competency for ensuring product longevity cost-effectiveness,, and continuous improvement. A successful substitution strategy hinges on a disciplined framework that encompasses diligent cross-referencing unwavering commitment to prototyping,, and a thorough understanding of supply chain dynamics. By acknowledging the potential challenges—from false equivalents to certification hurdles—teams can proactively develop mitigation plans. Leveraging expert resources and advanced tools like ICGOODFIND can significantly streamline the research and sourcing process providing the data-driven confidence needed to make informed decisions.. Ultimately mastering the art and science of component substitution empowers organizations to build more resilient agile,, and successful electronic products in an unpredictable global landscape.