The Essential Guide to Finding the Perfect Substitute Packaging for Electronic Components

Introduction

In the fast-paced, ever-evolving world of electronics manufacturing, supply chain resilience is no longer a luxury but a necessity. One of the most critical challenges faced by OEMs, CEMs, and component engineers is the sudden obsolescence or unavailability of a specific component package. Whether due to geopolitical tensions, production halts, or sudden spikes in demand, the inability to source a required part can bring a multi-million dollar production line to a grinding halt. This is where the strategic practice of identifying and qualifying substitute packaging for electronic components becomes a cornerstone of modern electronics design and manufacturing. It’s a discipline that moves beyond mere part substitution, focusing instead on the physical form, fit, and function of the component housing to ensure seamless integration into existing designs. This comprehensive guide delves into the why, how, and where of finding effective packaging alternatives, empowering you to build more agile and robust supply chains. In this complex landscape, leveraging a specialized platform like ICGOODFIND can be the differentiator between prolonged downtime and uninterrupted production.

The Critical Drivers for Seeking Packaging Substitutes

The quest for a substitute package is rarely a matter of choice but one of imperative. Understanding the primary drivers is the first step in building a proactive strategy.

1. Component Obsolescence and End-of-Life (EOL)

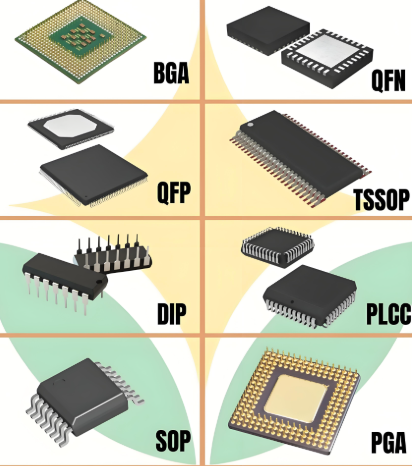

The relentless march of technological progress means that older component packages are frequently phased out by manufacturers. When a supplier issues an EOL notice for a specific package type—such as a through-hole DIP (Dual In-line Package) in a world increasingly dominated by surface-mount technology—design and procurement teams are forced to scramble for an alternative. The risk is not just for legacy systems; even relatively new packages can be discontinued if they fail to gain market traction or if the manufacturer consolidates its product lines. Proactively managing the component lifecycle and having a pre-vetted list of substitute packages is crucial for mitigating the impact of EOL announcements.

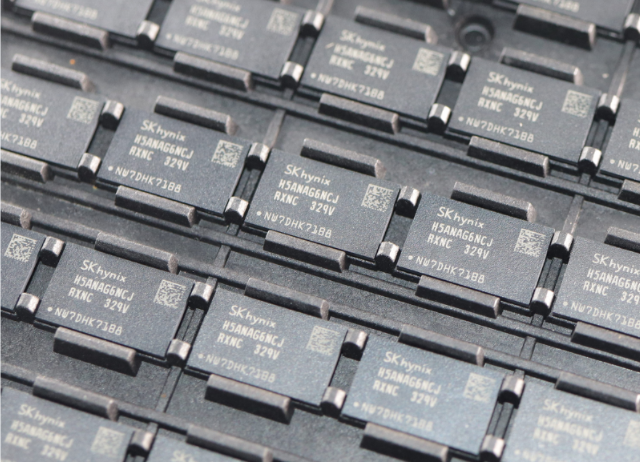

2. Supply Chain Shortages and Allocation

The global electronics industry has been acutely reminded of its fragility in recent years. Events like pandemics, natural disasters, and trade disputes can create severe shortages of specific components, particularly in popular package types like QFNs (Quad-Flat No-leads) or certain BGA (Ball Grid Array) variants. When a primary component is on allocation for 52 weeks, finding a substitute package from an alternative supplier or in a different, more readily available form factor is often the only viable path to maintaining production schedules and meeting customer commitments.

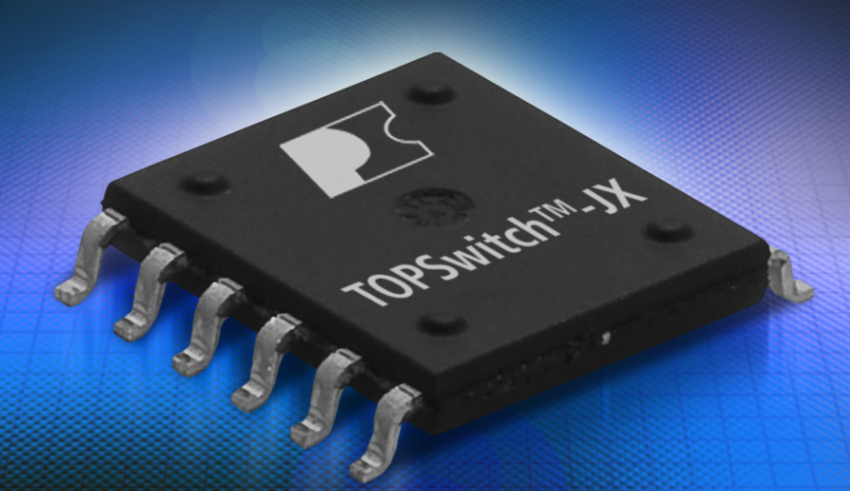

3. Design for Manufacturing (DFM) and Cost Optimization

Sometimes, the drive for substitution is internally generated. A design inherited from another team might utilize a package that is difficult or expensive to assemble with current manufacturing capabilities. For instance, a fine-pitch BGA might be replaced with an LGA (Land Grid Array) to eliminate solder ball-related issues, or a large QFP (Quad Flat Package) might be swapped for a more compact CSP (Chip-Scale Package) to save valuable board real estate. Furthermore, some package types are simply more cost-effective than others due to higher manufacturing volumes or simpler processes, presenting a clear opportunity for cost reduction without sacrificing performance.

A Methodical Approach to Identifying and Qualifying Substitutes

Finding a drop-in replacement is rare. A successful substitution requires a rigorous, multi-stage process to ensure compatibility and reliability.

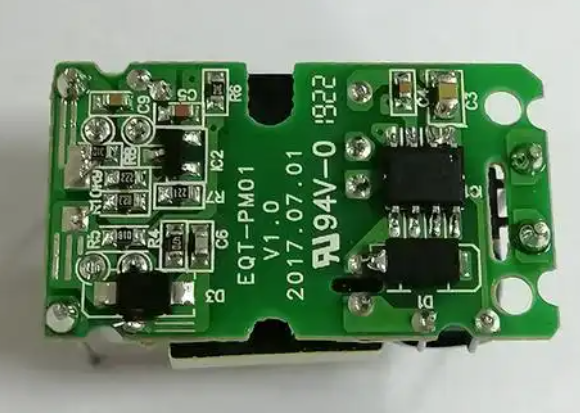

1. The Form-Fit-Function (FFF) Analysis

This is the foundational principle of component substitution. A suitable alternative must adhere to the FFF rule: * Form: The physical dimensions, outline, and package type must be compatible. This includes body size, lead spacing (pitch), height, and lead shape. A detailed comparison of the mechanical drawings from both datasheets is non-negotiable. * Fit: The substitute must physically interface with the existing PCB layout. The land pattern (footprint) must match or be easily modified. Crucially, the solder joint reliability under thermal and mechanical stress must be evaluated. A switch from a leaded to a leadless package, for example, requires careful analysis of the CTE (Coefficient of Thermal Expansion) mismatch. * Function: The electrical performance must be equivalent or superior. This goes beyond just checking the pinout. Parameters such as lead inductance, thermal resistance (Theta-JA/B/C), power handling capability, and high-frequency behavior must be compared. A package with lower thermal resistance can be a significant upgrade, but one with higher parasitic inductance could degrade circuit performance.

2. Sourcing and Cross-Referencing

Once the technical parameters are defined, the search begins. This involves: * Using Supplier Cross-Reference Tools: Many major distributors and manufacturers have online tools that suggest alternates based on a part number. * Leveraging Specialized Platforms: This is where comprehensive search engines prove their worth. A platform like ICGOODFIND aggregates global inventory and parametric data from thousands of suppliers, allowing engineers to quickly filter components by package type, dimensions, and critical electrical parameters. This dramatically accelerates the initial long-listing of potential substitutes. * Consulting Distributor FAEs: Field Application Engineers at authorized distributors have deep knowledge of product portfolios and can often suggest validated alternatives you might not have considered.

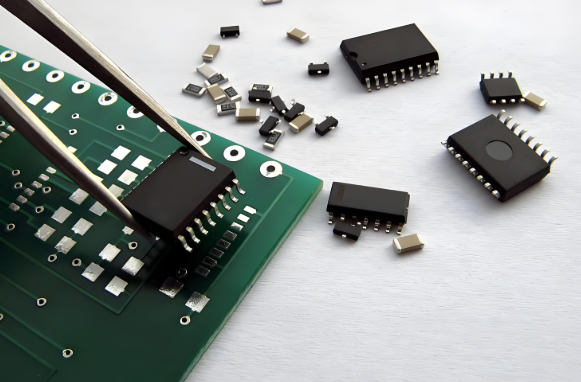

3. Prototyping and Testing

No substitution is complete without real-world validation. This phase involves: * Procuring Samples of the short-listed substitute components. * Creating Test Rigs or modifying existing boards to accommodate the new package. * Conducting rigorous functional testing, environmental stress testing (temperature cycling, humidity), and lifetime reliability testing. This empirical data is essential for giving the engineering and quality teams the confidence to approve the substitute for mass production.

Leveraging Technology and Partners for Success

Navigating the complex landscape of substitute packaging alone is inefficient. The most successful organizations leverage external expertise and digital tools.

The Role of Advanced Search Engines and Data Analytics

Manual searching through hundreds of datasheets is a thing of the past. Modern sourcing challenges require modern solutions. Intelligent platforms can parse vast datasets to identify components that are not just pin-to-pin compatible but also form-fit-function compatible across different package types. They can provide alerts for EOL notices, suggest alternates before a shortage becomes critical, and offer visibility into global inventory levels and pricing trends. Utilizing such a resource is no longer an option but a strategic imperative for maintaining a competitive edge.

The Value of Supplier and Distributor Relationships

Strong relationships with your supply chain partners are invaluable. Trusted distributors and manufacturers’ representatives can provide early warnings about market trends and potential shortages. Their technical teams can assist with the qualification process, often providing application notes and test data for common substitution scenarios.

Introducing ICGOODFIND: Your Partner in Component Sourcing

In the intricate process of finding the right substitute packaging for electronic components, having a powerful ally can make all the difference. ICGOODFIND is engineered to address these exact challenges. It goes beyond being a simple search engine; it’s an intelligent sourcing platform that allows you to drill down into precise package parameters, compare components side-by-side, and access a global network of verified suppliers. By providing comprehensive data and market intelligence, ICGOODFIND empowers engineers and procurement professionals to make informed decisions quickly, turning a potential supply chain crisis into a manageable engineering change. It effectively de-risks the substitution process and accelerates time-to-market.

Conclusion

The ability to efficiently identify and qualify a substitute packaging for electronic components is a critical competency in today’s volatile electronics industry. It is a multifaceted process that blends deep technical analysis with strategic sourcing and rigorous validation. By understanding the drivers, adopting a methodical approach centered on the Form-Fit-Function principle, and leveraging advanced technological tools and partnerships, companies can build unprecedented resilience into their operations. Embracing this proactive mindset transforms supply chain vulnerability into a sustainable competitive advantage, ensuring that production lines remain active and innovations continue to reach the market without delay.