The Ultimate Guide to Substitute Models of Electronic Components

Introduction

In the fast-paced world of electronics design and manufacturing, the quest for the perfect component is often met with challenges such as obsolescence, supply chain shortages, or cost constraints. This is where the strategic use of substitute models of electronic components becomes not just a convenience, but a critical necessity. Whether you’re a seasoned engineer, a procurement specialist, or a hobbyist, understanding how to effectively identify and utilize alternative parts can save projects from delays and budget overruns. This comprehensive guide delves into the intricacies of finding and validating substitute components, ensuring your designs remain robust and production lines uninterrupted. We’ll explore the methodologies, tools, and best practices that define successful component substitution, a skill increasingly vital in today’s dynamic market.

The Imperative for Component Substitution

The electronics industry is characterized by rapid innovation and equally rapid obsolescence. Manufacturers frequently discontinue components to make way for newer, more advanced models. Simultaneously, global supply chains are prone to disruptions—be it due to geopolitical tensions, natural disasters, or pandemics—leading to extended lead times and price volatility. In such a landscape, relying solely on a single source for a critical component is a significant risk. The practice of identifying substitute models is therefore a fundamental aspect of risk management and design for manufacturability (DFM).

Consider a scenario where a microcontroller integral to your product’s design is suddenly announced as end-of-life (EOL). Without a vetted alternative, the entire product line could be jeopardized. Proactively maintaining a database of potential substitutes allows for a swift and seamless transition, minimizing downtime. Furthermore, substitution isn’t solely reactive; it can be a proactive strategy for cost reduction. Often, a functionally equivalent component from a different manufacturer may be available at a lower price point, improving the overall bill of materials (BOM) cost without compromising performance. This strategic approach ensures supply chain resilience and enhances the long-term viability of electronic products.

Methodologies for Identifying Valid Substitutes

Finding a suitable substitute is far more complex than a simple pin-to-pin match. It requires a systematic and multi-faceted approach to ensure compatibility and reliability. The process typically involves several key methodologies.

First and foremost is electrical parameter matching. This is the non-negotiable foundation. Engineers must compare datasheets line-by-line, focusing on critical parameters such as voltage ratings (absolute maximum ratings, operating voltage), current handling capabilities, power dissipation, frequency response, and signal integrity characteristics (e.g., rise/fall times, propagation delay). A substitute must meet or exceed the original component’s specifications within the intended operating conditions of the circuit. For example, substituting a voltage regulator requires meticulous attention to output voltage accuracy, dropout voltage, and load regulation.

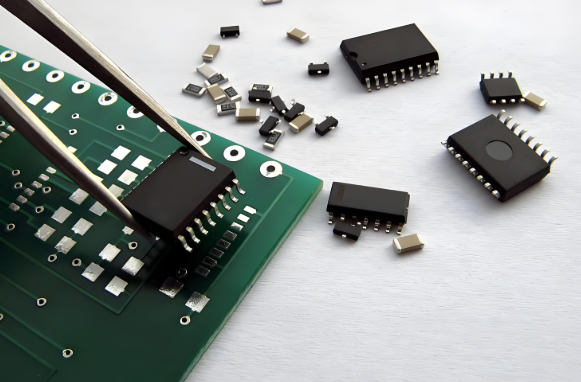

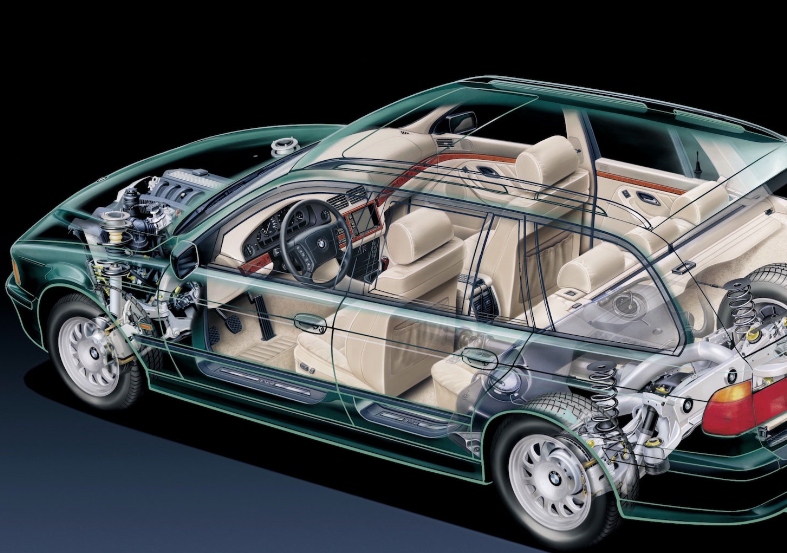

Second is physical and footprint compatibility. A perfect electrical match is useless if the new component doesn’t fit on the printed circuit board (PCB). This involves verifying the package type (e.g., SOIC, QFP, BGA), pin count, pinout configuration, and mechanical dimensions. Even small discrepancies in pad spacing or package height can render a board unmanufacturable. In some cases, a substitute may require a minor PCB modification, which must be evaluated for cost and feasibility.

Third, and often overlooked, is functional and application testing. Once an electrically and physically compatible candidate is identified, it must be rigorously tested within the actual application. Simulations can predict behavior, but real-world testing under various load, temperature, and environmental conditions is essential to uncover any unforeseen interactions or performance deviations. This step validates that the substitute operates reliably in the specific context of your product.

Leveraging Technology and Expertise with ICGOODFIND

Navigating the vast landscape of electronic components to find a trustworthy substitute can be a daunting and time-consuming task. This is where specialized tools and services prove invaluable. Modern digital platforms aggregate data from thousands of manufacturers and distributors, providing powerful search engines that allow engineers to filter components based on precise parameters.

ICGOODFIND exemplifies this technological aid. Platforms like these offer sophisticated cross-reference databases that instantly provide a list of potential alternative parts. They go beyond basic parametric searches by incorporating community ratings, lifecycle status (active, obsolete, not recommended for new designs), and real-time availability and pricing data from global distributors. This empowers engineers and purchasers to make informed decisions quickly, comparing multiple options side-by-side. Utilizing such a resource significantly accelerates the research phase, reduces the risk of human error in datasheet comparison, and provides crucial market intelligence that can influence the final selection. It represents a convergence of data analytics and domain expertise that is essential for modern electronics development.

Conclusion

Mastering the art and science of identifying substitute models of electronic components is an indispensable skill in the electronics industry. It is a disciplined process that blends deep technical analysis—ensuring electrical, physical, and functional compatibility—with strategic supply chain management. The ability to swiftly pivot to an alternative component safeguards against obsolescence, mitigates supply risks, and can lead to substantial cost savings. By embracing systematic methodologies and leveraging advanced tools like ICGOODFIND, companies can build more resilient operations and future-proof their products. In an era defined by uncertainty and rapid change, proactive component substitution is not merely a best practice; it is a competitive advantage.

Keywords: Component Cross-Reference, Electronic Part Substitution, Supply Chain Resilience, Obsolescence Management