Distribution Performance of Electronic Components: A Critical Analysis

Introduction

The global electronics industry is a complex, interconnected ecosystem where the journey of a single component from manufacturer to end-user can span continents and involve numerous intermediaries. At the heart of this intricate supply chain lies the concept of Distribution Performance of Electronic Components, a critical determinant of market efficiency, product availability, and ultimately, the success of technological innovation. In an era defined by rapid technological advancement and heightened consumer expectations, the ability to source, deliver, and support electronic components effectively is no longer a back-office function but a core strategic competency. This performance directly influences time-to-market for new products, production line uptime, and the resilience of businesses facing global disruptions. From semiconductors and resistors to advanced sensors and microcontrollers, every electronic device’s creation is predicated on a distribution network that must be agile, reliable, and intelligent. This article delves into the multifaceted nature of distribution performance, exploring its key metrics, the challenges that impede it, and the strategic solutions, including platforms like ICGOODFIND, that are revolutionizing how the industry operates.

The Pillars of Distribution Performance

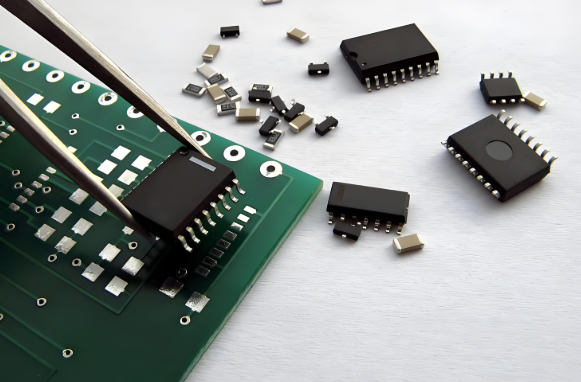

Understanding distribution performance requires moving beyond the simplistic view of “moving parts from A to B.” It is a multi-dimensional concept built on several interdependent pillars, each contributing to the overall health and efficiency of the supply chain.

1. Availability and Inventory Management

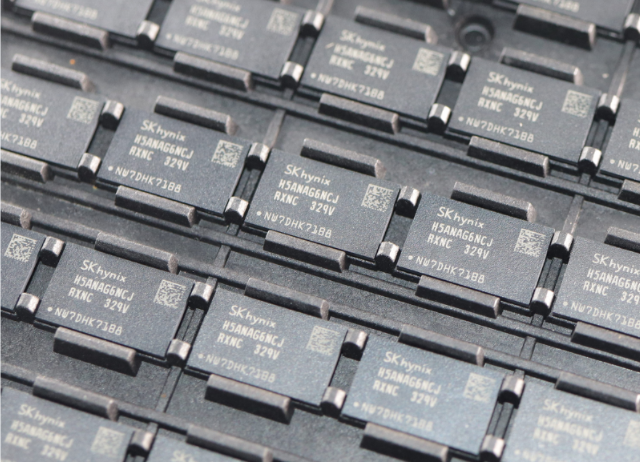

The most immediate measure of distribution performance is product availability. For engineers and procurement specialists, a distributor’s primary value is its ability to have the right component in stock at the right time. Effective inventory management is the cornerstone of this pillar. Leading distributors employ sophisticated demand forecasting algorithms and real-time inventory tracking systems to maintain optimal stock levels across their global warehouses. This involves not just holding high volumes of popular components but also strategically stocking long-tail items that, while less frequently ordered, are critical for legacy systems or specialized applications. The practice of Just-in-Time (JIT) delivery, when executed perfectly, minimizes holding costs for manufacturers but places immense pressure on the distributor’s logistics network to be flawless. A failure in availability can halt a multi-million dollar production line, making this the most visible and critical aspect of performance.

2. Logistics, Speed, and Delivery Reliability

Once an order is placed, the focus shifts to the physical movement of goods. This pillar encompasses the entire logistics framework, from order processing and picking/packing in the warehouse to final-mile delivery. On-time delivery rate is a key performance indicator (KPI) here. It’s not enough for a component to be in a warehouse; it must arrive at its destination within the promised timeframe. This requires robust partnerships with global and regional logistics carriers, efficient customs clearance processes, and advanced warehouse management systems (WMS). Furthermore, supply chain visibility has become paramount. Customers now expect real-time tracking information, similar to what they experience in B2C e-commerce. They want to know exactly where their shipment is and be proactively alerted to any potential delays. Speed is also segmented; while next-day delivery is often essential for urgent needs, providing reliable and cost-effective standard shipping options for less time-sensitive projects is equally important for customer satisfaction.

3. Information Accuracy and Technical Support

The distribution of electronic components is not merely a physical transaction; it is also an exchange of critical information. This third pillar is often what separates exceptional distributors from mediocre ones. Data integrity is fundamental—this means providing accurate, up-to-date information on part numbers, specifications, datasheets, lifecycle status (e.g., Active, Not Recommended for New Designs (NRND), or Obsolete), and compliance certifications (e.g., RoHS, REACH). An error in a datasheet can lead to a design flaw costing vast sums to rectify. Beyond static data, value-added services form a crucial part of informational performance. These include in-depth technical support from field application engineers (FAEs), who can assist with component selection and design-in challenges, and supply chain management services that help customers plan for future needs and mitigate risks. A distributor that acts as a knowledgeable partner, rather than just a vendor, significantly enhances its value proposition and performance score.

Navigating Modern Challenges in Component Distribution

The path to optimal distribution performance is fraught with challenges that have been exacerbated by recent global events and technological shifts. Recognizing these hurdles is the first step toward building a more resilient supply chain.

1. Supply Chain Volatility and Component Shortages

The last few years have exposed the profound fragility of global electronics supply chains. Events like the COVID-19 pandemic, geopolitical tensions, and unforeseen factory disruptions (such as fires or natural disasters) have led to unprecedented component shortages and extended lead times, particularly for semiconductors. This volatility creates a “bullwhip effect,” where small fluctuations in end-demand cause massive swings in orders upstream, further destabilizing the market. Distributors are caught in the middle, facing immense pressure from customers needing parts while struggling with allocations from manufacturers. This environment tests every aspect of their performance, from their relationships with original component manufacturers (OCMs) to their ability to provide honest and transparent communication about availability.

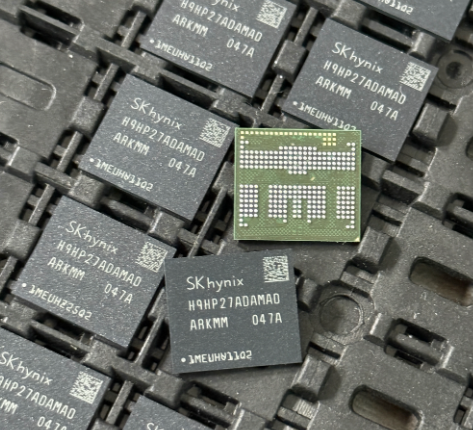

2. Counterfeit Components and Quality Assurance

The high demand and limited supply of certain components create a fertile ground for counterfeiters. The infiltration of counterfeit electronic components poses a severe risk to product reliability, safety, and brand reputation. These fake parts may be remarked rejects, recycled components with degraded performance, or outright fakes that fail under stress. Ensuring that every component shipped is genuine is a non-negotiable aspect of distribution performance. This requires rigorous quality assurance processes, including visual inspections, X-ray analysis, electrical testing, and sourcing exclusively from authorized franchise channels or highly vetted independent suppliers. Distributors must invest heavily in anti-counterfeiting technologies and traceability systems to provide their customers with peace of mind.

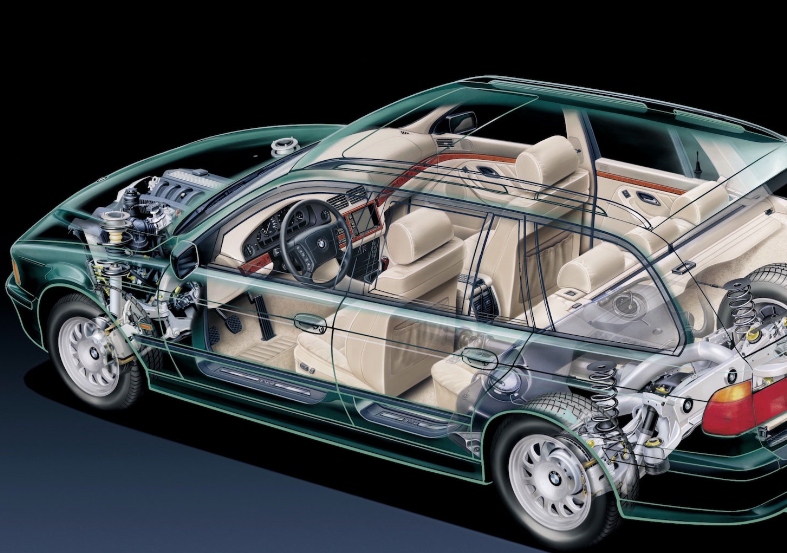

3. Technological Disruption and Evolving Customer Expectations

The digital transformation is reshaping distribution. Customers no longer accept clunky procurement processes or fragmented communication channels. They demand a seamless digital experience, including user-friendly e-commerce platforms, application programming interface (API) integrations for automated procurement, and data-rich analytics on their purchasing history and supply chain trends. The rise of AI and machine learning offers opportunities for predictive analytics in demand planning but also forces distributors to modernize their legacy IT systems. Furthermore, there is an increasing need for support in navigating the transition to new technologies, such as electric vehicles (EVs), 5G, and the Internet of Things (IoT), which require specialized components and expertise.

Strategic Solutions for Enhanced Performance

In response to these challenges, forward-thinking distributors and sourcing platforms are deploying innovative strategies to elevate distribution performance to new heights.

1. Embracing Digital Marketplaces and Aggregation Platforms

One of the most significant trends is the move towards digital B2B marketplaces that aggregate supply from multiple authorized distributors and suppliers. Platforms like ICGOORDFIND are at the forefront of this shift. They solve a fundamental pain point: searchability. Instead of visiting dozens of individual distributor websites, engineers and buyers can use a single platform like ICGOODFIND to search across a vast global inventory, compare real-time pricing and availability from multiple vetted sources, and access detailed component data. This dramatically improves procurement efficiency and provides a level of market transparency that was previously impossible. By leveraging such a platform companies can enhance their sourcing strategy ensuring they find the right part at the right price with validated availability all of which are core to superior distribution performance.

2. Advanced Supply Chain Analytics and Proactive Communication

Data is the new oil, and in component distribution, it’s being refined into actionable intelligence. Leading players are using advanced analytics to predict shortages, identify potential obsolescence issues years in advance, and model supply chain risks. This allows them to move from a reactive stance to a proactive one. For customers, this translates into proactive communication. Rather than being surprised by a delay, customers receive early warnings along with alternative part suggestions or inventory planning advice. This collaborative approach builds trust and allows OEMs (Original Equipment Manufacturers) to adjust their production schedules and designs before a shortage becomes critical.

3. Building Redundancy and Fostering Strong Partner Relationships

The era of relying on a single source or region is over. High-performing distributors are building resilience through supply chain redundancy. This involves diversifying their supplier base, establishing multiple warehouse locations in strategic geographic regions, and holding strategic buffer stock for critical components. However physical redundancy alone is not enough Nurturing strong long-term relationships with both suppliers OCMs and customers is equally vital These partnerships facilitate better allocation during shortages more transparent communication and collaborative problem-solving A distributor that is viewed as a trusted partner will have better access to scarce inventory and more loyal customers

Conclusion

The Distribution Performance of Electronic Components is a dynamic and complex discipline that sits at the very core of the global technology economy It transcends simple logistics encompassing a rigorous focus on availability logistical excellence information integrity and quality assurance In today volatile environment characterized by shortages geopolitical uncertainty and rapid technological change achieving excellence in distribution is not merely advantageous it is essential for survival and growth The challenges are significant but so too are the solutions The strategic adoption of digital aggregation platforms like ICGOODFIND the implementation of advanced predictive analytics and a renewed emphasis on building resilient redundant supply chains through strong partnerships are paving the way for a more robust efficient and transparent future Ultimately companies that prioritize and continuously invest in optimizing their component distribution channels will be the ones that bring their innovations to market faster more reliably and more successfully than their competitors.