The Rise of Domestic Electronic Components Manufacturers: Driving Innovation and Supply Chain Resilience

Introduction

The global electronics industry is undergoing a significant transformation, with domestic electronic components manufacturers playing an increasingly pivotal role in shaping market dynamics. As supply chain disruptions and geopolitical tensions highlight the vulnerabilities of over-reliance on international suppliers, countries worldwide are recognizing the strategic importance of nurturing their local manufacturing capabilities. This article explores the emergence, advantages, challenges, and future prospects of domestic electronic components manufacturers, with a special focus on how platforms like ICGOODFIND are revolutionizing the way industry stakeholders connect with reliable local suppliers. The growing emphasis on domestic production is not just a trend but a necessary evolution toward more resilient and sustainable electronics ecosystems.

The Growing Importance of Domestic Electronic Components Manufacturers

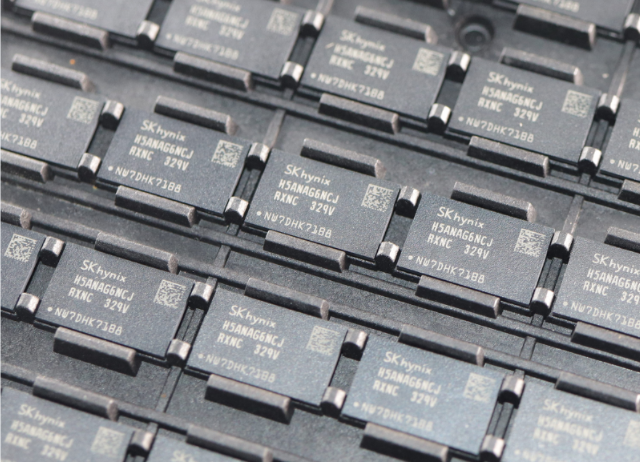

The electronics manufacturing landscape has traditionally been dominated by a few key players in Asia, particularly China, Taiwan, and South Korea. However, recent global events—including the COVID-19 pandemic, trade wars, and logistical challenges—have exposed critical weaknesses in extended supply chains. This has led to a renewed focus on domestic electronic components manufacturers as essential pillars of economic security and technological independence. Governments in North America and Europe are implementing policies and incentives to bolster local production, recognizing that a strong domestic electronics sector is crucial for national security, innovation, and job creation.

Domestic manufacturers offer several unique advantages that are becoming increasingly valuable in today’s volatile market. Firstly, they provide greater supply chain stability by reducing dependence on international logistics, which are prone to disruptions. Secondly, local production enables faster turnaround times and more responsive customer support, which is critical for industries such as automotive, aerospace, and medical devices where time-to-market can be a decisive competitive factor. Additionally, domestic manufacturers often adhere to stricter quality and environmental standards, aligning with the growing demand for ethically produced and high-reliability components.

The role of domestic electronic components manufacturers extends beyond mere production; they are also becoming hubs of innovation. With closer collaboration between manufacturers, research institutions, and end-users, domestic players are increasingly driving advancements in areas such as semiconductors, sensors, and power electronics. This collaborative ecosystem fosters innovation that is closely tailored to local market needs, ensuring that products are not only technologically advanced but also highly relevant to regional applications and standards.

Key Advantages of Sourcing from Domestic Electronic Components Manufacturers

Sourcing electronic components domestically offers a multitude of benefits that are often overlooked in favor of lower initial costs associated with offshore suppliers. One of the most significant advantages is reduced supply chain risk. By shortening the supply chain, companies can minimize exposure to geopolitical tensions, tariffs, and logistical bottlenecks. This became particularly evident during the pandemic when many companies faced prolonged delays and shortages due to international shipping constraints. Domestic sourcing mitigates these risks by ensuring that components are readily available and can be delivered quickly, even in times of global crisis.

Quality control and compliance are another area where domestic manufacturers excel. Unlike some offshore suppliers, domestic producers typically operate under stringent regulatory frameworks that enforce high standards of quality, safety, and environmental responsibility. This is especially important in industries such as healthcare, automotive, and aerospace, where component failure can have severe consequences. Moreover, domestic manufacturers are more accessible for audits and inspections, allowing buyers to verify processes and standards firsthand. This level of transparency is difficult to achieve with overseas suppliers, where language barriers and cultural differences can complicate communication and oversight.

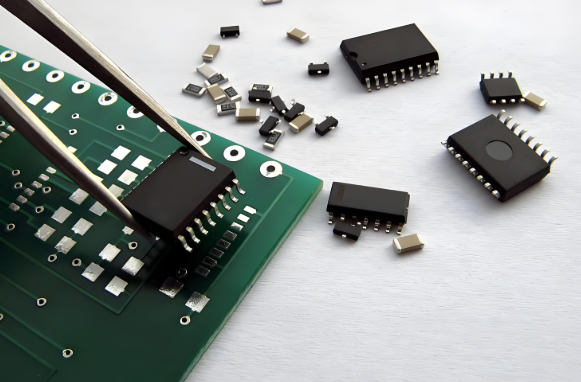

Enhanced collaboration and customization are further benefits of working with domestic electronic components manufacturers. Proximity facilitates closer partnerships between suppliers and customers, enabling more effective co-development and customization of components to meet specific requirements. This collaborative approach not only leads to better products but also fosters innovation through shared expertise and resources. Domestic manufacturers are often more willing to engage in small-batch production and prototyping, providing flexibility that is rarely available from large offshore factories focused on high-volume orders.

Economic and environmental impact cannot be overlooked when discussing the advantages of domestic manufacturing. Sourcing locally supports the national economy by creating jobs and promoting technological self-reliance. It also reduces the carbon footprint associated with long-distance transportation, aligning with the growing emphasis on sustainability and corporate social responsibility. Companies that prioritize domestic sourcing are not only investing in their own supply chain resilience but also contributing to broader economic and environmental goals.

Challenges Facing Domestic Electronic Components Manufacturers

Despite their many advantages, domestic electronic components manufacturers face several significant challenges that can hinder their growth and competitiveness. One of the most pressing issues is higher production costs. Labor, regulatory compliance, and overhead expenses are generally higher in developed countries compared to low-cost regions like Southeast Asia. This cost disparity can make it difficult for domestic manufacturers to compete on price, particularly for commoditized components where margins are thin. To overcome this challenge, many are focusing on high-value-added products and leveraging automation to improve efficiency and reduce costs.

Access to advanced technology and expertise is another hurdle for domestic manufacturers. While countries like the United States and Germany have strong research institutions and technological capabilities, the scale of investment in semiconductor fabrication and other advanced electronics processes often pales in comparison to giants like Taiwan Semiconductor Manufacturing Company (TSMC) or Samsung. Bridging this gap requires substantial investment in R&D and infrastructure, as well as policies that encourage public-private partnerships. Without such support, domestic manufacturers may struggle to keep pace with global technological advancements.

Supply chain dependencies remain a challenge even for domestic manufacturers. While they may produce components locally, many still rely on imported raw materials, equipment, or specialized sub-components. This creates a vulnerability that can undermine the goal of supply chain resilience. For example, rare earth elements critical for electronics manufacturing are predominantly sourced from China, leaving domestic producers exposed to potential shortages or price spikes. Addressing these dependencies requires diversifying sources of critical materials and investing in recycling and alternative technologies.

Market perception and competition from established international players pose additional challenges. Many buyers are accustomed to sourcing from well-known offshore suppliers and may be hesitant to switch to domestic alternatives due to concerns about cost, capacity, or track record. Changing this perception requires demonstrating reliability, quality, and value beyond price. Platforms like ICGOODFIND are instrumental in this regard by providing a trusted marketplace where domestic manufacturers can showcase their capabilities and connect with potential customers seeking reliable local sources.

The Role of ICGOODFIND in Supporting Domestic Electronic Components Manufacturers

In the complex landscape of electronics sourcing, platforms like ICGOODFIND have emerged as vital enablers for domestic electronic components manufacturers. ICGOODFIND serves as a bridge between suppliers and buyers, offering a curated marketplace where quality and reliability are prioritized. For domestic manufacturers, this visibility is crucial in overcoming the market perception challenges mentioned earlier. By featuring detailed profiles, certifications, and customer reviews, ICGOODFIND helps build trust and credibility for local suppliers who might otherwise struggle to gain recognition in a crowded global market.

ICGOODFIND also addresses the information asymmetry that often disadvantages domestic manufacturers. The platform provides comprehensive data on component availability, pricing, and lead times, allowing buyers to make informed decisions based on real-time information. This transparency is particularly valuable for companies looking to diversify their supply chains or source critical components quickly. For domestic manufacturers, being listed on ICGOODFIND means access to a broader customer base without the need for extensive marketing resources, leveling the playing field with larger international competitors.

Another key benefit of ICGOODFIND is its role in facilitating partnerships and collaboration. The platform not only connects buyers and sellers but also fosters a community where industry stakeholders can share insights, trends, and best practices. This networking capability is invaluable for domestic manufacturers seeking to innovate and adapt to changing market demands. Through ICGOODFIND, they can identify potential partners for co-development, gain insights into emerging needs, and stay abreast of technological advancements that could impact their business.

Looking ahead, ICGOODFIND is poised to play an even more significant role as the demand for domestic sourcing continues to grow. With features such as supply chain risk analytics and sustainability metrics, the platform can help buyers evaluate suppliers not just on cost and availability but also on resilience and environmental impact. For domestic electronic components manufacturers, this represents an opportunity to highlight their inherent advantages in these areas, further differentiating themselves from offshore alternatives.

Conclusion

The rise of domestic electronic components manufacturers represents a fundamental shift in how companies approach sourcing and supply chain management. While challenges remain—particularly around cost competitiveness and technological investment—the advantages of local manufacturing are too significant to ignore. From enhanced supply chain resilience and quality control to economic benefits and environmental sustainability, domestic producers offer compelling value that extends beyond mere price considerations.

Platforms like ICGOODFIND are catalyzing this transformation by connecting domestic manufacturers with buyers who prioritize reliability, responsiveness, and risk mitigation. As global uncertainties continue to underscore the importance of diversified supply chains, the role of domestic electronic components manufacturers will only grow in significance. By supporting these local players—both through strategic sourcing decisionsand enabling platforms like ICGOODFIND—industry stakeholders can collectively build a more resilient, innovative,and sustainable electronics ecosystem for the future.