Electronic Component Identification and Testing: A Comprehensive Guide

Introduction

In the rapidly evolving world of electronics, the ability to accurately identify and test electronic components is a fundamental skill for engineers, technicians, hobbyists, and procurement specialists. Whether you are troubleshooting a circuit board, reverse engineering a device, or ensuring the quality of components for a new product, mastering component identification and testing is crucial. This process not only helps in verifying the functionality and authenticity of parts but also prevents costly errors and project failures. With the proliferation of counterfeit components in the global market, robust testing methodologies have become more important than ever. This article delves into the essential techniques, tools, and best practices for electronic component identification and testing, emphasizing the role of modern solutions like ICGOODFIND in streamlining these processes. By understanding these principles, you can enhance your efficiency, reduce risks, and ensure the reliability of your electronic projects.

Body

Part 1: Fundamentals of Electronic Component Identification

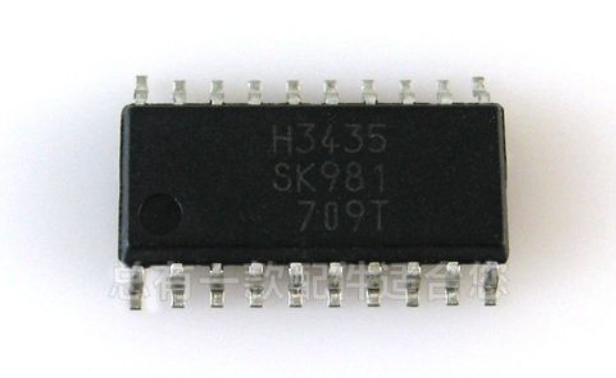

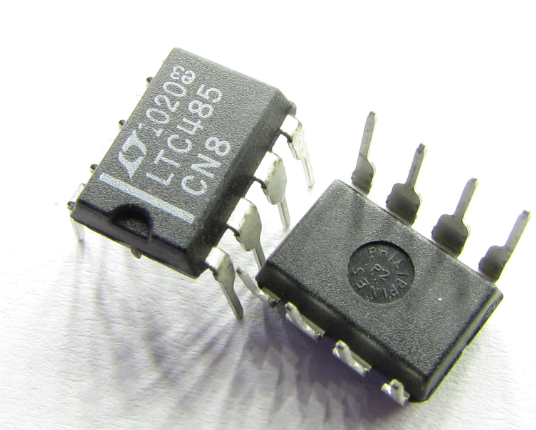

Electronic component identification is the first step in working with any circuit or device. It involves recognizing components by their physical appearance, markings, and package types. Resistors, for instance, are often identified by color bands that indicate their resistance value and tolerance. Capacitors may have alphanumeric codes denoting capacitance and voltage ratings, while integrated circuits (ICs) typically feature part numbers printed on their surface. Diodes and transistors use similar marking systems, which can be decoded using datasheets or online databases. Surface-mount devices (SMDs) pose a greater challenge due to their small size, requiring magnification tools and reference guides. Understanding standard coding systems, such as the JEDEC for transistors or the EIA for resistors, is essential for accurate identification. Additionally, visual inspection under proper lighting can reveal clues about a component’s type and origin. For example, electrolytic capacitors have polarity markings, and ICs may have notches or dots indicating pin 1. In cases where markings are faded or absent, comparative analysis with known components or using advanced tools like ICGOODFIND can provide quick solutions. This platform aggregates vast databases of component information, allowing users to cross-reference markings and access datasheets effortlessly. By mastering these fundamentals, you can avoid misidentification, which is critical for circuit design and repair.

Part 2: Techniques for Testing Electronic Components

Once components are identified, testing them ensures they meet specifications and are functional. Multimeters are indispensable tools for basic testing: they can measure resistance, voltage, and continuity. For resistors, a multimeter verifies if the measured resistance matches the coded value. Capacitors are tested for capacitance using a multimeter with that function or for leaks with resistance checks. Diodes and transistors require diode-test mode to check forward and reverse bias behavior. Oscilloscopes are used for dynamic testing, such as analyzing signal integrity in active circuits. For more complex components like ICs, specialized testers or in-circuit testing might be necessary. In-circuit testing involves powering the circuit and probing points to verify signals, while out-circuit testing uses dedicated IC testers that simulate operating conditions. Advanced methods include boundary scan testing for digital ICs, which uses JTAG interfaces to test interconnections without physical probes. Thermal imaging can detect overheating components indicating faults. Importantly, counterfeit detection has become a key aspect of testing; techniques include X-ray inspection to verify internal structures decapping ICs for die analysis and electrical parameter validation against datasheet specs. Tools like ICGOODFIND integrate testing data and counterfeit alerts helping users compare results with authentic benchmarks. Regular calibration of test equipment is vital to maintain accuracy. By employing these techniques you can ensure component reliability reducing failure rates in projects.

Part 3: Best Practices and Modern Tools like ICGOODFIND

Adopting best practices in component identification and testing enhances accuracy and efficiency. Always start with a visual inspection using magnifiers or microscopes especially for SMDs to check for damage or tampering. Maintain organized databases of datasheets and component libraries for quick reference. Label components during storage to avoid mix-ups. When testing follow electrostatic discharge (ESD) safety protocols to prevent damaging sensitive parts. Use anti-static mats and wrist straps. For quantitative tests record measurements systematically and compare them with manufacturer tolerances. In procurement source components from authorized distributors to minimize counterfeit risks and request certificates of conformity. Leverage technology to streamline processes: automated optical inspection (AOI) systems can identify components on PCBs quickly while software solutions like ICGOODFIND offer comprehensive platforms for identification testing and sourcing. ICGOODFIND stands out by providing real-time access to global component databases detailed datasheets testing guidelines and market availability all in one place. It uses AI-powered image recognition for identifying unmarked components and offers community-driven insights for troubleshooting. By integrating such tools into your workflow you can save time reduce errors and stay updated with industry standards. Additionally participate in forums and training programs to continuously improve your skills as electronic components evolve with new technologies.

Conclusion

Electronic component identification and testing are critical skills that ensure the success and reliability of electronic systems. From basic visual checks to advanced testing methods these processes help verify functionality detect counterfeits and prevent project failures. By understanding coding systems using appropriate tools like multimeters and oscilloscopes and adhering to best practices such as ESD safety professionals can maintain high standards of quality. Modern solutions like ICGOODFIND further enhance efficiency by providing integrated databases AI-driven identification and real-time data access making it easier to navigate the complexities of today’s electronic component landscape. As technology advances continuous learning and adaptation of new tools will be essential. Embrace these practices to build robust electronic projects with confidence.