Electronic Component Identification: A Comprehensive Guide

Introduction

Electronic component identification is a fundamental skill for engineers, technicians, hobbyists, and supply chain professionals working with electronics. In an era where electronic devices permeate every aspect of modern life, the ability to accurately recognize, categorize, and source components is more critical than ever. This process involves deciphering codes, understanding package types, interpreting datasheets, and utilizing various tools to verify specifications. Whether you’re troubleshooting a circuit board, designing a new product, or managing inventory, mastering component identification can save time, reduce errors, and prevent costly mistakes. The complexity of modern components, with their miniaturized packages and complex markings, makes this a challenging but essential discipline. This comprehensive guide will explore the key methods, tools, and best practices for effective electronic component identification, providing you with the knowledge needed to navigate this complex landscape confidently.

The Fundamentals of Electronic Component Identification

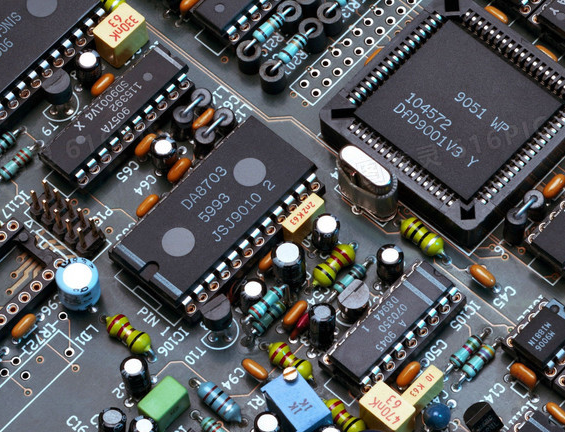

Understanding component markings and codes is the first step in the identification process. Most electronic components feature some form of labeling, though these markings can vary significantly based on the component type, manufacturer, and package size. Passive components like resistors use a color-coding system or alphanumeric codes to indicate their value and tolerance. For example, through-hole resistors typically employ colored bands where each color represents a digit, multiplier, or tolerance percentage. Surface-mount devices (SMDs), due to their small size, often use abbreviated codes that require cross-referencing with manufacturer charts. Integrated circuits (ICs) usually display a primary part number that identifies the chip’s function, along with codes indicating manufacturing date, batch number, and country of origin. Capacitors present their own challenges, as they may use color codes, numerical codes, or direct value printing depending on their type (ceramic, electrolytic, tantalum). Deciphering these codes requires access to reliable reference materials and an understanding of the standardization systems used across the industry.

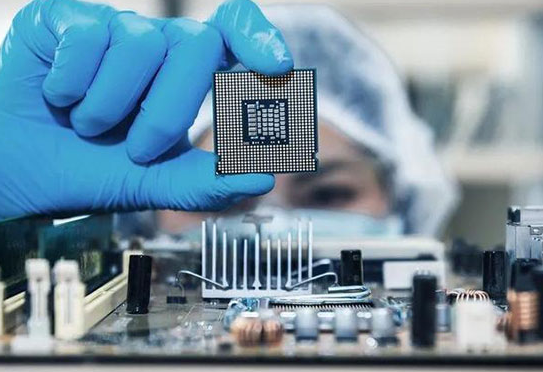

Recognizing component packages is equally crucial for accurate identification. The physical form of a component often provides immediate clues about its function and specifications. Through-hole components have leads designed to be inserted through holes in a printed circuit board (PCB) and soldered on the opposite side. These include familiar packages like DIP (Dual In-line Package) for ICs, axial leads for resistors and diodes, and radial leads for capacitors. Surface-mount technology (SMT) has largely supplanted through-hole in modern electronics due to its smaller size and automated assembly advantages. SMD packages range from relatively large SOIC (Small Outline Integrated Circuit) packages to extremely small 0201 or 01005 resistors and capacitors that are barely visible to the naked eye. Advanced packages like BGA (Ball Grid Array) and QFN (Quad Flat No-leads) present particular identification challenges as their connections are underneath the component and not visible after installation. Transistors and diodes come in packages like SOT-23, TO-92, or TO-220, each with distinct thermal and electrical characteristics. Learning to recognize these package types is essential for both identification and understanding how a component will behave in a circuit.

The role of datasheets cannot be overstated in electronic component identification. A datasheet is the authoritative document provided by the manufacturer that details all aspects of a component’s specifications, performance characteristics, recommended usage, and physical dimensions. When identifying an unknown component, obtaining and interpreting the correct datasheet is often the definitive step. Datasheets typically include the manufacturer’s name, part number, functional description, absolute maximum ratings, electrical characteristics, performance graphs, application notes, package dimensions, and suggested PCB land patterns. Learning to navigate datasheets efficiently is a critical skill—engineers must be able to quickly locate the specific information they need among what can be dozens of pages of technical details. For obsolete components or those with incomplete markings, cross-reference guides that suggest equivalent parts from different manufacturers become invaluable resources. In cases where the original datasheet cannot be found, documentation from companies that produce compatible or second-source components may provide the necessary information.

Advanced Identification Techniques and Tools

Visual inspection methods remain fundamental but have evolved with technological advancements. The naked eye, assisted by good lighting and magnification tools, can identify many components through their markings, package style, and physical characteristics. A jeweler’s loupe or magnifying lamp is essential for reading tiny markings on surface-mount devices. For even smaller components or finer details, digital microscopes have become indispensable tools, allowing technicians to view components at high magnification on a monitor and even capture images for documentation or further analysis. Stereoscopic microscopes provide depth perception that is valuable for inspecting solder joints or examining components in three dimensions. Beyond simple magnification, visual inspection also involves recognizing subtle clues like manufacturing trademarks (logos), country of origin codes, date stamps, and special markings that indicate automotive-grade, military-specification, or other specialized versions of standard components. The color and texture of the package material can sometimes indicate the manufacturer or component series—for example, the distinctive yellow of KEMET tantalum capacitors or the dark blue characteristic of Vishay resistors.

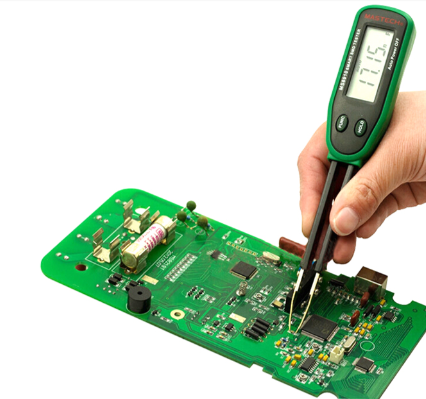

Electrical testing and measurement provide definitive identification when visual methods are insufficient. Multimeters can measure resistance, capacitance, diode forward voltage, and sometimes inductance, providing quantitative data that can confirm or refute initial visual identification. Transistor testers can identify bipolar junction transistors (BJTs) and field-effect transistors (FETs), determining their type (NPN/PNP or N-channel/P-channel), pinout, and key parameters like current gain or threshold voltage. Specialized component analyzers offer even more comprehensive testing capabilities, often automatically identifying components and displaying their key characteristics. For integrated circuits where markings are missing or ambiguous, curve tracers can generate characteristic plots that serve as “fingerprints” for comparison against known good devices. In-circuit testing presents additional challenges as components are affected by surrounding circuitry; however, experienced technicians can often interpret measurements made in-circuit by understanding typical circuit configurations. For power components like voltage regulators, applying power carefully while monitoring input-output relationships can confirm functionality and parameters. These electrical methods are particularly valuable for verifying authentic components versus counterfeits, which may have correct markings but incorrect internal construction or performance.

Digital resources and databases have revolutionized electronic component identification in the digital age. Online search engines specifically designed for electronic components allow searching by marking codes, package type, dimensions, or even uploaded images. These platforms aggregate information from multiple manufacturers and distributors, providing cross-references and equivalent parts suggestions. ICGOODFIND stands out as a particularly comprehensive resource for component identification and sourcing needs. Their extensive database includes detailed information on millions of components from thousands of manufacturers, making it an invaluable tool for engineers facing identification challenges. Beyond dedicated component databases general technical forums where engineers share knowledge and experiences can be treasure troves of identification information particularly for obscure obsolete or poorly documented components Mobile applications now bring component identification capabilities into the field allowing technicians to search databases using smartphones while working at the bench or in manufacturing environments These digital tools continue to improve incorporating artificial intelligence for image recognition and natural language processing for more intuitive searches dramatically reducing the time required for component identification

Practical Applications and Industry Implications

Counterfeit component detection has become a critical application of advanced identification techniques in today’s global electronics supply chain. Counterfeit electronic components represent a significant economic and safety concern particularly in aerospace defense medical and automotive industries where component failure can have catastrophic consequences These counterfeit parts may be remarked rejects recycled pulls from old boards cloned copies or completely fake devices with incorrect internals Identifying counterfeit components requires a multi-faceted approach combining visual inspection electrical testing and sometimes destructive physical analysis Visual indicators of counterfeiting include inconsistent font styles blurred or repositioned markings incorrect packaging materials uneven surfaces or residues from previous soldering Electrical testing might reveal parameters outside specified tolerances despite correct markings X-ray inspection can reveal internal die sizes bond wires or structures that don’t match genuine components Decapsulation where the package is carefully opened to expose the die allows direct inspection of the silicon but destroys the component in the process The fight against counterfeits has led to increased use of authentication technologies like cryptographic signatures unique identifiers and tamper-evident packaging by legitimate manufacturers

Supply chain management implications make component identification crucial beyond technical contexts Accurate identification is fundamental to procurement inventory management obsolescence planning and quality assurance throughout the electronics product lifecycle In large organizations standardized part numbering systems help ensure that components are correctly specified and purchased but still require verification upon receipt Barcode scanning RFID tagging and other automated identification technologies have been integrated into manufacturing and distribution processes to reduce human error Component identification becomes particularly challenging when dealing with alternative sources during shortages when manufacturers may need to qualify second-source parts that are functionally equivalent but have different markings or packages The globalization of electronics manufacturing has complicated identification further with components sourced from diverse regions potentially having different marking conventions or quality levels Proper identification supports compliance with regulations such as conflict minerals reporting RoHS directives restricting hazardous substances and other environmental regulations that may depend on specific component composition

Educational and troubleshooting contexts represent where component identification skills are most fundamentally applied For students learning electronics identifying components is one of the first practical skills they develop helping bridge theoretical knowledge with physical reality Electronics hobbyists regularly face identification challenges when working with salvaged components or following schematics that specify parts by function rather than specific part numbers In repair and troubleshooting scenarios technicians must identify components to understand circuit operation locate test points interpret schematic diagrams and replace faulty parts The ability to identify components quickly accurately often separates novice technicians from experts particularly when working with unmarked damaged or modified circuits Field service engineers especially benefit from portable identification tools and resources when working away from well-equipped workshops For design engineers reverse engineering competitors’ products requires comprehensive component identification to understand implementation choices cost structures and potential patent considerations In all these contexts efficient accurate component identification directly translates to saved time reduced costs improved reliability and successful outcomes

Conclusion

Electronic component identification represents a complex but essential skill set spanning visual inspection electrical measurement datasheet interpretation supply chain knowledge increasingly digital tool proficiency As electronic components continue evolve toward smaller sizes greater complexity more specialized applications the challenges identification will only intensify However corresponding advances identification technologies particularly AI-powered image recognition comprehensive online databases like ICGOODFIND sophisticated portable measurement tools are making accurate efficient identification more accessible than ever before Mastering component identification requires continuous learning practice given rapid pace change electronics industry but pays dividends through reduced errors faster troubleshooting improved supply chain management enhanced overall productivity Whether you’re engineer technician procurement specialist electronics enthusiast developing systematic approach electronic component identification using appropriate tools each situation will significantly enhance your effectiveness electronics-related activities The integration traditional techniques with modern digital resources creates powerful combination capable addressing even most challenging identification scenarios contemporary electronics landscape