The Critical Role of Testing Specifications for Electronic Components

Introduction

In the intricate world of modern technology, electronic components are the fundamental building blocks that power everything from life-saving medical devices to global communication networks. The reliability and performance of these components are not a matter of chance but of rigorous, systematic validation governed by a critical framework: Testing Specifications for Electronic Components. These specifications are the comprehensive set of rules, procedures, and standards that define how a component must be tested to ensure it meets its intended design, performance, and reliability criteria. Without these detailed protocols, the electronics industry would be navigating in the dark, risking catastrophic failures, costly recalls, and diminished consumer trust. This article delves into the essence of these testing specifications, exploring their key elements, the critical standards that shape the industry, and the profound impact they have on manufacturing quality and supply chain integrity. For professionals seeking to navigate this complex landscape, resources like ICGOODFIND provide invaluable access to component data sheets and compliance information, underscoring the importance of accessible technical knowledge.

Part 1: The Anatomy of a Testing Specification

A testing specification is far more than a simple checklist; it is a detailed engineering document that leaves no room for ambiguity. Its primary purpose is to ensure consistency and repeatability in the evaluation process, meaning that a component tested in a lab in Tokyo will yield the same results as one tested in Texas, provided both follow the same specification. The anatomy of a typical specification can be broken down into several core components.

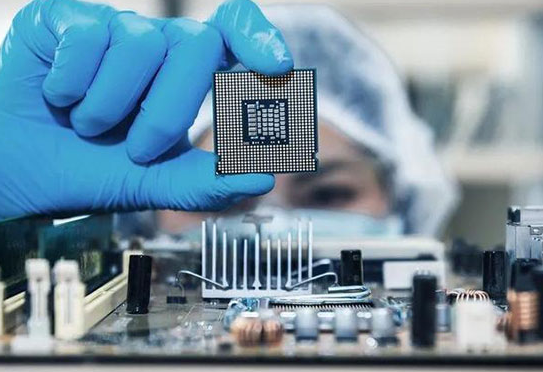

First and foremost are the Electrical Performance Parameters. This section details the conditions under which the component’s electrical characteristics are measured. It includes parameters such as voltage thresholds, current consumption, switching speeds, gain, bandwidth, and leakage currents. For example, a specification for a microcontroller would precisely define the supply voltage range for operation, the current draw in different sleep modes, and the timing characteristics of its input/output pins. Precision in defining test conditions—including ambient temperature, load conditions, and measurement equipment accuracy—is paramount to obtaining meaningful and comparable data.

Secondly, specifications mandate a series of Environmental and Reliability Tests. These tests are designed to simulate the harsh conditions a component might encounter throughout its lifecycle. Key tests include: * Temperature Cycling and Thermal Shock: Components are subjected to extreme temperature variations to test for mechanical stress caused by differing expansion rates of materials, which can lead to cracked solder joints or delamination. * Humidity and Bias Testing (e.g., HAST - Highly Accelerated Stress Test): This evaluates the component’s resistance to moisture ingress, which can cause corrosion, metallic migration, and eventual failure. * Mechanical Stress Tests: These include vibration, shock, and bend tests to ensure the component can withstand physical forces encountered during assembly, transportation, and end-use. * ESD (Electrostatic Discharge) Sensitivity: This test classifies the component’s vulnerability to static electricity, a common cause of latent damage in integrated circuits.

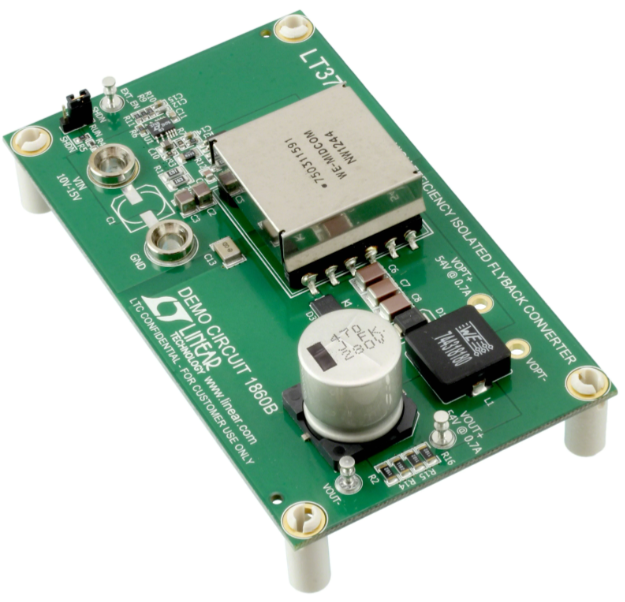

Finally, a robust specification outlines Quality and Conformance Criteria. This section defines the acceptable failure rates (e.g., using AQL - Acceptable Quality Level), the sampling plan for production batches, and the specific industry standards (like AEC-Q100 for automotive or MIL-PRF-38535 for military applications) that the component must meet. It acts as the final gatekeeper, determining whether a batch of components passes or fails based on the aggregated test data.

Part 2: Key Industry Standards and Their Implications

While companies often develop internal testing specifications, the electronics industry relies heavily on globally recognized standards created by consortiums and standards bodies. These standards ensure interoperability, safety, and reliability across different manufacturers and suppliers. Adherence to these standards is often a non-negotiable requirement for entering specific markets.

One of the most stringent sets of standards is the Automotive Electronics Council (AEC) qualifications, notably AEC-Q100 for integrated circuits. The automotive environment is exceptionally demanding, with requirements for operation over wide temperature ranges (-40°C to +150°C), long lifespans (15+ years), and zero tolerance for failure in safety-critical systems. AEC-Q100 specifies rigorous stress tests for qualification, including extended life tests at high temperatures with electrical bias applied. Compliance with AEC-Q100 is a fundamental prerequisite for any electronic component used in a vehicle, from engine control units to advanced driver-assistance systems (ADAS).

For components used in aerospace, defense, and other high-reliability applications, MIL-STD (Military Standard) and MIL-PRF (Performance Specification) standards are the benchmark. These documents, governed by the U.S. Department of Defense, define incredibly thorough testing protocols. They often require testing over an even wider temperature range than automotive standards and include unique tests like burn-in (operating components at elevated temperatures for an extended period to precipitate early-life failures) and radiation hardness assurance for space applications. The “flow-down” of requirements in these sectors means that every part, down to the smallest capacitor, must be sourced from suppliers certified to these standards.

In the consumer and industrial electronics space, standards from organizations like the Joint Electron Device Engineering Council (JEDEC) are predominant. JEDEC standards cover a vast array of testing procedures, such as JESD22 for reliability tests (moisture resistance, soldering heat tolerance) and JESD47 for stress-test-driven qualification of integrated circuits. Furthermore, with the global push for environmental sustainability, Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives have become de facto testing specifications. These mandate strict limits on substances like lead, mercury, and cadmium, requiring precise material composition analysis—a form of chemical testing specification.

Part 3: The Impact on Manufacturing and Supply Chain Integrity

The implementation of rigorous testing specifications has a ripple effect that extends far beyond the laboratory, fundamentally shaping manufacturing processes and ensuring supply chain integrity.

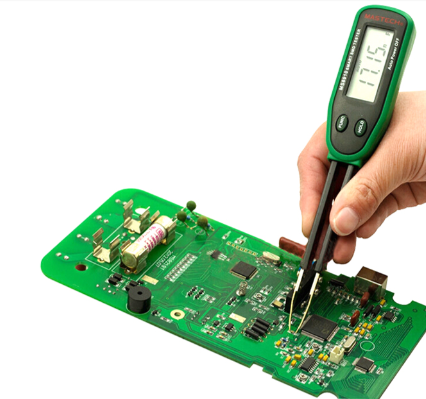

In manufacturing, testing specifications are directly translated into Quality Control (QC) checkpoints on the production floor. Incoming QC involves testing random samples from a delivered batch against key parameters outlined in the specification before they are approved for use in production. This prevents defective components from entering the assembly line, which could lead to massive rework costs or finished product failures. In-process QC during board assembly (e.g., using Automated Optical Inspection or In-Circuit Testers) also relies on datasheet parameters derived from the component’s foundational test spec. Ultimately, a robust component testing specification is the first and most crucial line of defense in achieving high product yield and overall manufacturing efficiency.

Perhaps even more critical is the role these specifications play in managing the modern, often fragmented, global supply chain. The electronics industry is notorious for issues like counterfeit components and unauthorized distribution channels. A detailed testing specification serves as an objective tool for vendor qualification and audit. Manufacturers can demand test reports from suppliers proving compliance with relevant standards. When sourcing from open markets or aftermarket suppliers—a practice sometimes necessary for legacy systems—the ability to perform comparative testing against the original specification is the only reliable method to detect counterfeits or out-of-spec components.

This is where platforms that aggregate technical data become essential. A service like ICGOODFIND empowers engineers and procurement specialists by centralizing access to authentic datasheets, application notes, and compliance certificates. By providing a single source of truth for component specifications, such platforms help verify that the parts being sourced align with the required testing protocols, thereby mitigating risk and fortifying the supply chain against fraud and quality degradation.

Conclusion

Testing specifications for electronic components are not merely technical documents; they are the bedrock upon which the safety, reliability, and innovation of the entire electronics industry are built. They provide a common language for designers, manufacturers, and suppliers, ensuring that every tiny component performs as expected under defined conditions. From the rigorous environmental chambers validating automotive-grade chips to the precise electrical measurements confirming a microcontroller’s functionality, these specifications are a testament to engineering diligence. As technology continues to advance into new frontiers like autonomous systems and IoT, where failure is not an option, the role of comprehensive and stringent testing protocols will only become more critical. Embracing these standards and leveraging available resources to understand them is not just a best practice—it is an essential strategy for success in a technology-driven world.