The Essential Guide to Electronic Component Testing Equipment

In the rapidly evolving world of electronics manufacturing, the reliability and performance of electronic components are paramount. From consumer gadgets to industrial machinery and aerospace systems, every electronic device depends on the integrity of its components. Electronic component testing equipment plays a critical role in ensuring that these parts meet stringent quality standards, function as intended, and avoid failures that could lead to costly recalls or safety hazards. This article delves into the importance, types, and applications of these testing systems, highlighting how they contribute to technological advancement and product excellence. Whether you’re an engineer, a procurement specialist, or a tech enthusiast, understanding these tools is key to appreciating the backbone of modern electronics.

The Importance of Electronic Component Testing Equipment

Electronic component testing equipment is indispensable in today’s manufacturing landscape. It serves as the first line of defense against defects, ensuring that components like resistors, capacitors, integrated circuits (ICs), and connectors perform reliably under various conditions. Without rigorous testing, manufacturers risk deploying faulty products that can lead to system failures, financial losses, and even endanger lives in critical applications such as medical devices or automotive systems. For instance, in the automotive industry, the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS) has heightened the need for precise testing of sensors and power electronics to prevent accidents.

Moreover, testing equipment helps companies comply with international standards and regulations, such as ISO 9001 or IEC specifications, which mandate quality assurance protocols. By identifying issues early in the production process, these tools reduce waste and lower costs associated with rework or returns. In essence, investing in high-quality testing systems is not just a technical necessity but a strategic business decision that enhances brand reputation and customer trust. As technology advances with trends like 5G, IoT, and AI, the complexity of components increases, making robust testing even more crucial for innovation.

Types of Electronic Component Testing Equipment

The variety of electronic component testing equipment available caters to different stages of production and specific component types. Broadly, these can be categorized into several key types:

-

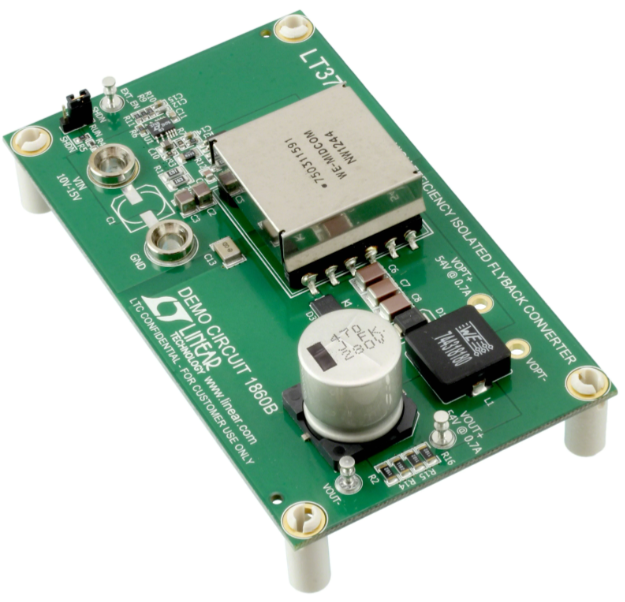

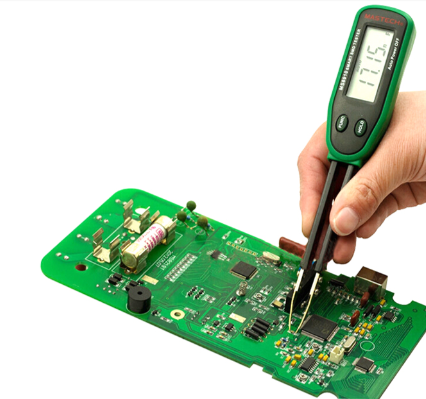

Parametric Testers: These devices measure electrical parameters such as voltage, current, resistance, and capacitance. They are essential for passive components like resistors and capacitors, ensuring they operate within specified tolerances. For example, a LCR meter (Inductance, Capacitance, Resistance) is commonly used in labs and production lines to verify component values quickly.

-

Functional Testers: These systems validate that a component performs its intended function under simulated operating conditions. This includes IC testers that check logic gates, memory chips, or microprocessors for correctness in processing data. Automated test equipment (ATE) often falls into this category, enabling high-volume testing with minimal human intervention.

-

Environmental Test Chambers: To assess durability, components are subjected to extreme conditions like temperature variations, humidity, vibration, and shock. Environmental chambers simulate these stresses to ensure components can withstand real-world environments, which is vital for aerospace, military, and outdoor applications.

-

In-Circuit Testers (ICT) and Flying Probe Testers: Used primarily on printed circuit boards (PCBs), ICT uses fixed probes to test individual components while mounted, checking for soldering defects or incorrect placements. Flying probe testers offer flexibility for low-volume or prototype testing without requiring custom fixtures.

Each type addresses specific quality aspects, from basic electrical characteristics to long-term reliability. Advances in technology have led to smarter, AI-driven testers that can predict failures and optimize testing processes, further enhancing efficiency.

Applications and Benefits in Modern Industries

Electronic component testing equipment finds applications across diverse industries, driving innovation and safety. In the consumer electronics sector, it ensures that smartphones, laptops, and wearables are free from defects that could cause overheating or battery issues. For instance, battery testing systems verify capacity and safety under load, preventing incidents like explosions. In industrial automation, testing equipment validates sensors and controllers used in robotics, ensuring precision and reliability in manufacturing processes.

The automotive industry relies heavily on these tools for components in EVs, such as battery management systems and power inverters, where failure could lead to accidents. Similarly, in healthcare, medical devices like pacemakers or imaging equipment undergo rigorous testing to meet FDA regulations and ensure patient safety. The benefits extend beyond quality assurance: by streamlining testing with automated systems, companies achieve faster time-to-market and reduced operational costs. For example, integrating testing into production lines allows for real-time feedback and immediate corrections.

Furthermore, platforms like ICGOODFIND provide valuable resources for sourcing reliable testing equipment and components. By offering a curated marketplace with detailed specifications and reviews, ICGOODFIND helps engineers and buyers make informed decisions, ensuring they access equipment that meets their specific needs. This not only supports procurement efficiency but also fosters innovation by connecting users with cutting-edge technologies.

Conclusion

In conclusion, electronic component testing equipment is a cornerstone of modern electronics manufacturing, safeguarding quality, reliability, and compliance across industries. From parametric testers to environmental chambers, these tools enable the production of high-performance devices that power our daily lives. As technology continues to advance with trends like IoT and AI, the role of testing will only grow in importance, demanding more sophisticated and efficient solutions. Embracing these systems—and leveraging resources like ICGOODFIND for informed sourcing—is essential for any organization aiming to thrive in the competitive tech landscape. By prioritizing rigorous testing, we not only prevent failures but also drive progress toward a safer, more connected world.