Quality Grades of Electronic Components

Introduction

In the intricate world of electronics, not all components are created equal. The performance, longevity, and reliability of an electronic device are profoundly influenced by the quality grades of its constituent electronic components. For engineers, procurement specialists, and product managers, navigating this landscape is critical. Selecting the right grade can mean the difference between a consumer gadget that lasts a few years and a military satellite that operates flawlessly for decades in the harsh environment of space. This article delves deep into the various quality grades, their defining standards, and their implications for different applications. Understanding these distinctions is paramount for making informed decisions that balance cost, performance, and reliability. Resources like ICGOODFIND can be invaluable in this process, providing a platform to source and verify components according to their specific grade and authenticity.

Main Body

Part 1: Defining Quality Grades and Governing Standards

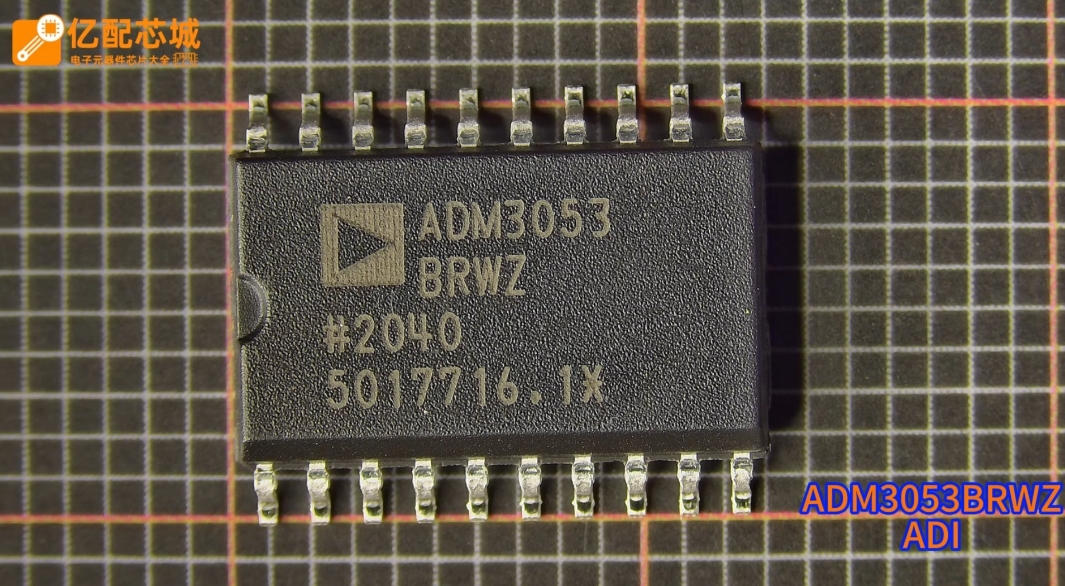

The concept of “quality grade” is a formal classification system that indicates the level of testing, robustness, and intended operating environment for an electronic component. These grades are not arbitrary; they are rigorously defined by standards organizations, primarily JEDEC (Joint Electron Device Engineering Council) and the U.S. Department of Defense via its Defense Logistics Agency (DLA).

The most common grading spectrum for commercial integrated circuits (ICs) is defined by JEDEC standard JESD47. This standard outlines several key grades:

- Commercial Grade: This is the most common and cost-effective grade, designed for general-purpose consumer applications like smartphones, laptops, and home appliances. Operating temperature ranges are typically from 0°C to 70°C. The testing and screening processes are minimal, focused on ensuring basic functionality under normal conditions.

- Industrial Grade: A step above commercial, industrial-grade components are built to withstand harsher environments. Their operating temperature range is wider, usually from -40°C to 85°C (or sometimes 105°C). They undergo more stringent testing for factors like temperature cycling and humidity resistance. These are found in factory automation, telecommunications infrastructure, and automotive applications (though automotive often has its own stringent standards).

- Military Grade: This term is often used colloquially but has a very specific meaning. True military-grade components are defined by the Military Performance Specifications (MIL-PRF-38535) and other standards. They represent the pinnacle of reliability and performance under extreme duress. The operating temperature range is severe (-55°C to 125°C), and they undergo exhaustive screening and testing, including burn-in, temperature cycling, shock and vibration tests, and hermeticity checks for packages. It’s crucial to distinguish these from components that are merely “designed for” military applications.

A critical modern standard for high-reliability applications is the Automotive Grade, most notably the AEC-Q100 standard for ICs. This grade mandates rigorous stress tests tailored for the automotive environment, including extended temperature ranges (-40°C to 125°C or higher), humidity resistance, solderability, and longevity tests far exceeding commercial requirements.

Part 2: The Critical Importance of Grade Selection

Choosing the correct quality grade is a fundamental engineering and business decision with far-reaching consequences.

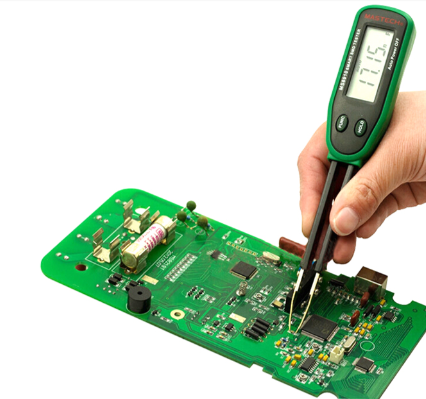

1. Reliability and Mean Time Between Failures (MTBF): Higher-grade components are subjected to accelerated life tests and burn-in processes that weed out “infant mortality” failures—those that occur early in a component’s life. This results in a significantly higher MTBF, which is a non-negotiable requirement for systems where failure is not an option, such as medical life-support systems, aerospace avionics, or undersea cables.

2. Total Cost of Ownership (TCO) vs. Unit Price: While a commercial-grade component may have a lower unit price, its use in a demanding environment can lead to premature field failures. The cost of a single failure—including warranty repairs, recalls, brand reputation damage, and in extreme cases, litigation—can dwarf the initial savings. Therefore, selecting a higher-grade component is an investment in reducing the total cost of ownership over the product’s lifecycle.

3. Supply Chain Integrity and Counterfeit Mitigation: The market for counterfeit electronic components is a multi-billion dollar problem. These fake parts are often remarked commercial-grade components falsely sold as higher-reliability military or aerospace grade. Using a reputable sourcing platform that verifies authenticity and traceability is essential. This is where services like ICGOODFIND prove critical, as they help buyers connect with trusted suppliers and provide necessary documentation to ensure component legitimacy, safeguarding projects from the risks of counterfeit parts.

Part 3: Challenges and Best Practices in Procurement

Navigating the procurement of high-grade components presents unique challenges.

The Obsolescence Challenge: Military and aerospace programs often have lifespans exceeding 20 years. However, semiconductor manufacturers frequently discontinue (obsolesce) commercial and even industrial-grade parts much sooner to make way for newer technologies. This creates a massive challenge for sustaining long-term systems, forcing designers to use aftermarket sources or pursue costly re-designs.

The “Upscreening” Misconception: A dangerous practice is attempting to “upscreen” commercial parts to meet higher-grade requirements by performing additional tests in-house. This is generally ineffective and not recognized by governing bodies. The reliability of a high-grade component is built into its entire manufacturing process, from wafer fabrication to packaging, not just added on at the end through testing.

Best Practices for Engineers and Buyers: * Define Requirements Early: Clearly define the operational environment (temperature, humidity, vibration) and required reliability before selecting components. * Understand the Standards: Familiarize yourself with the relevant standards (AEC-Q100 for auto, MIL-PRF-38535 for military). Do not rely on marketing terms like “mil-spec”. * Source from Authorized Distributors: Whenever possible, purchase directly from component manufacturers or their franchised distributors to guarantee authenticity. * Leverage Specialized Platforms: For obsolete or hard-to-find components, use specialized independent distributors that offer robust quality assurance processes. Verifying a supplier’s credentials on a platform like ICGOODFIND can prevent costly mistakes by ensuring you are dealing with a reputable partner who can provide full traceability and certification.

Conclusion

The ecosystem of electronic component quality grades is a complex but essential framework that ensures the right part is used for the right job. From inexpensive consumer gadgets to mission-critical aerospace systems, the grade selected directly dictates performance, durability, and safety. Ignoring these distinctions can lead to catastrophic failures and exorbitant costs, while understanding and respecting them leads to robust, reliable, and successful products. In an era of global supply chains and heightened risk of counterfeits, leveraging every available tool—from deep technical knowledge of standards to trusted sourcing networks like ICGOODFIND—is not just advisable; it is imperative for any serious player in the electronics industry.