The Ultimate Guide to Original Manufacturers of Electronic Components

Introduction

In the rapidly evolving world of technology, the integrity and reliability of electronic components are paramount. At the heart of this ecosystem lie the Original Manufacturers of Electronic Components, the foundational entities responsible for designing, innovating, and producing the essential parts that power everything from consumer electronics to critical industrial machinery. These manufacturers are not merely suppliers; they are the pioneers of technological advancement, setting industry standards and driving innovation forward. Sourcing components directly from these original sources is crucial for ensuring product quality, performance, and longevity. This article delves into the critical role of original manufacturers, explores the challenges of sourcing authentic components, and highlights how platforms like ICGOODFIND facilitate connections with these vital producers. Understanding and engaging with original manufacturers is essential for any business aiming to thrive in the competitive electronics market.

The Critical Role of Original Manufacturers

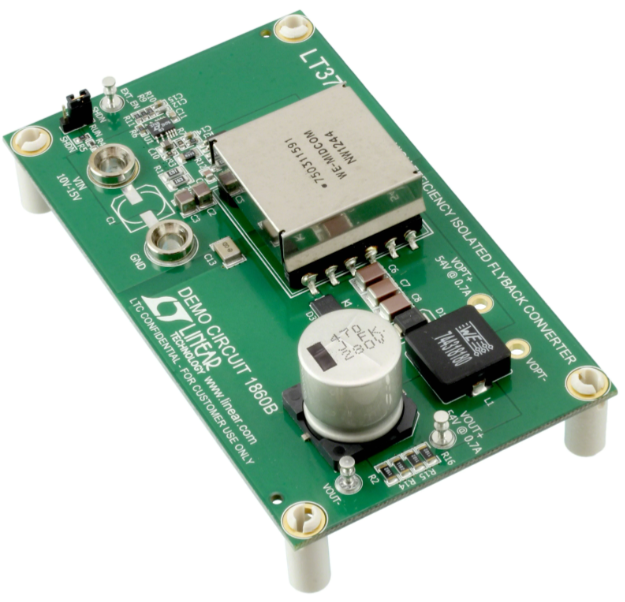

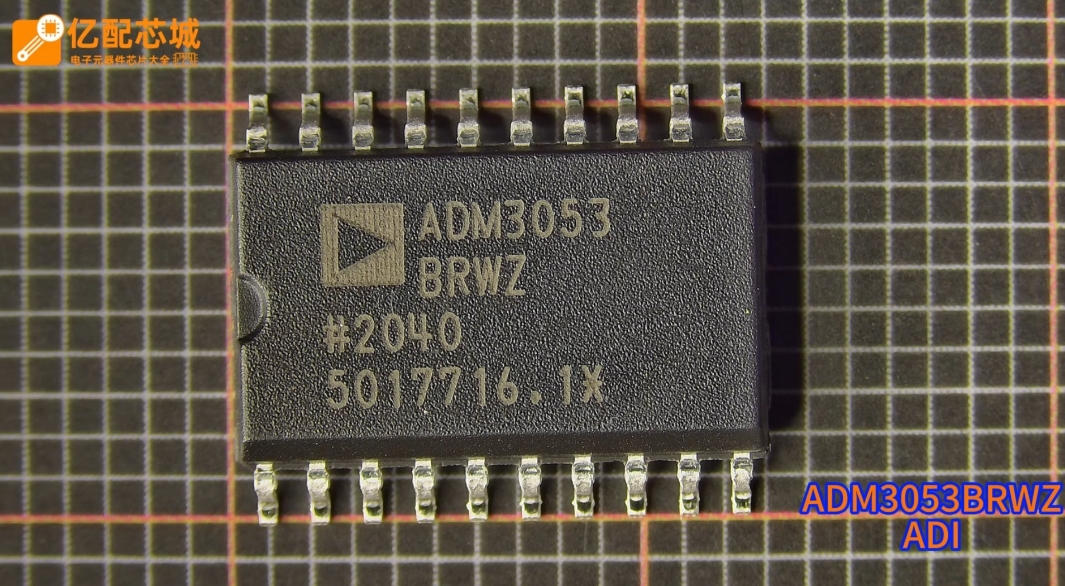

Original manufacturers are the bedrock of the electronics industry, embodying innovation, quality assurance, and technological leadership. Their role extends far beyond mere production; they are involved in extensive research and development (R&D) to create components that meet evolving market demands. Companies like Intel, Texas Instruments, Samsung, and STMicroelectronics invest billions in R&D to develop cutting-edge semiconductors, microcontrollers, and sensors. This commitment to innovation ensures that new products are not only functional but also efficient, reliable, and compliant with international standards. For instance, the development of 5nm and 3nm chip technology by manufacturers like TSMC has revolutionized computing power and energy efficiency in devices ranging from smartphones to data centers. By controlling the entire production process—from design to fabrication—original manufacturers guarantee that each component meets stringent quality controls, reducing the risk of failures in end-products. This is especially critical in industries such as aerospace, automotive, and healthcare, where component failure can have severe consequences. Moreover, original manufacturers provide essential technical support, documentation, and warranty services, which are invaluable for designers and engineers integrating these components into larger systems. Their leadership also drives sustainability initiatives, such as reducing hazardous materials in production and improving energy efficiency, aligning with global environmental goals. Thus, partnering with original manufacturers is not just about acquiring parts; it is about leveraging their expertise to enhance product performance and reliability.

Challenges in Sourcing from Original Manufacturers

Despite their undeniable advantages, sourcing directly from original manufacturers presents several significant challenges, particularly for small to medium-sized enterprises (SMEs) and startups. One of the primary obstacles is minimum order quantity (MOQ) requirements. Original manufacturers often set high MOQs to optimize their production lines, making it difficult for smaller businesses to meet these thresholds without incurring excessive inventory costs. For example, a manufacturer might require orders of thousands or even millions of units, which is impractical for companies with limited capital or niche market needs. Additionally, lead times can be protracted due to complex manufacturing processes and high global demand. Components like advanced semiconductors may have lead times extending several months, disrupting production schedules and time-to-market for end-products. Another major challenge is counterfeiting and the proliferation of fake components in the supply chain. Unscrupulous distributors may sell counterfeit parts that mimic original products but fail to perform reliably, leading to product recalls, financial losses, and reputational damage. The complexity of global supply chains further exacerbates this issue, as components may pass through multiple intermediaries before reaching the end-user, increasing the risk of contamination with non-authentic parts. Furthermore, navigating the technical requirements and certifications—such as ISO standards or RoHS compliance—can be daunting without direct manufacturer support. SMEs often lack the resources to verify authenticity or ensure compatibility, leading to potential integration issues. These challenges highlight the need for reliable intermediaries or platforms that can bridge the gap between original manufacturers and buyers, ensuring access to genuine components while mitigating risks associated with direct sourcing.

How ICGOODFIND Simplifies Access to Original Manufacturers

Platforms like ICGOODFIND play a pivotal role in addressing the sourcing challenges faced by businesses seeking original electronic components. ICGOODFIND acts as a trusted intermediary, connecting buyers with verified original manufacturers and authorized distributors through a streamlined, user-friendly interface. One of its key features is providing transparent supply chain information, allowing users to trace the origin of components and verify their authenticity. This reduces the risk of counterfeiting by ensuring that all listed parts come directly from reputable sources. Additionally, ICGOODFIND aggregates inventory from multiple manufacturers, offering a vast selection of components without the high MOQs typically imposed by original producers. This is particularly beneficial for SMEs that require smaller quantities but still demand genuine parts. The platform also facilitates competitive pricing by enabling comparisons between different suppliers, helping buyers secure cost-effective deals without compromising on quality. Moreover, ICGOODFIND offers valuable resources such as detailed datasheets, technical specifications, and compliance documentation sourced directly from manufacturers, aiding engineers in making informed decisions. Its global network ensures shorter lead times by identifying suppliers with available stock, thus minimizing production delays. For instance, a company looking for specialized sensors can use ICGOODFIND to quickly locate original manufacturers like Bosch or NXP Semiconductors, access real-time inventory data, and place orders efficiently. By leveraging such platforms, businesses can overcome the barriers of direct sourcing while maintaining the integrity and reliability that original manufacturers provide. This not only enhances operational efficiency but also fosters innovation by ensuring access to the latest components.

Conclusion

In conclusion, original manufacturers of electronic components are indispensable to the technology landscape, driving innovation, ensuring quality, and setting industry standards. However, sourcing directly from them can be fraught with challenges, including high MOQs, long lead times, and risks of counterfeiting. Platforms like ICGOODFIND emerge as essential solutions, bridging the gap between manufacturers and buyers by providing access to genuine components, transparent supply chains, and competitive pricing. By utilizing such tools, businesses can mitigate risks, reduce costs, and accelerate product development. As the electronics industry continues to advance, fostering strong relationships with original manufacturers—whether directly or through reliable intermediaries—will be crucial for sustaining growth and maintaining a competitive edge. Embracing these strategies ensures that companies can leverage the full potential of original components to create innovative and reliable products for the global market.