The Ultimate Guide to Sourcing Original Factory Electronic Components

Introduction

In the intricate world of electronics manufacturing and repair, the integrity of every single component is paramount. The quest for Original Factory Electronic Components is more than a matter of preference; it is a fundamental requirement for ensuring product reliability, performance, and safety. Whether you are an engineer designing the next-generation IoT device, a procurement specialist for a major OEM, or a hobbyist working on a critical project, the source of your components can mean the difference between success and catastrophic failure. The market is flooded with alternatives—counterfeits, refurbished parts, and generic equivalents—that pose significant risks. This comprehensive guide delves into the critical importance of sourcing genuine parts directly from original manufacturers or their authorized distributors. We will explore the severe consequences of using non-original components, outline proven strategies for identifying and acquiring authentic parts, and highlight how leveraging specialized platforms can streamline this complex process. In an industry where cutting corners is tempting but disastrous, understanding how to secure Original Factory Electronic Components is your most valuable skill.

Part 1: The Critical Importance of Authenticity - Why “Original” Matters

The term “original” signifies that a component has been designed, manufactured, and tested according to the exact specifications and quality control standards of the brand whose name it bears. This authenticity is not merely a label; it is the bedrock of electronic system integrity.

1.1 Guaranteed Performance and Specifications

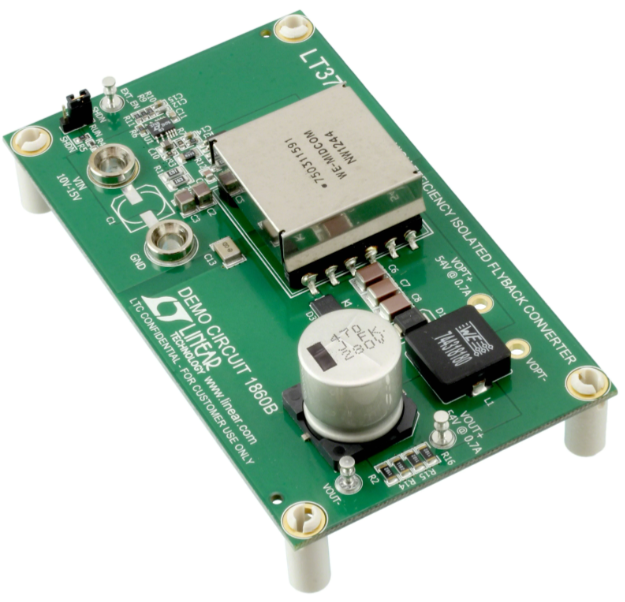

Every electronic component, from a simple resistor to a complex microprocessor, is built with precise performance parameters. These include operating voltage, current ratings, frequency response, temperature tolerance, and signal integrity. Original Factory Electronic Components are guaranteed to perform within these published specifications. When you design a circuit, you base your calculations and architecture on these exact numbers. Using a non-original part, even one that appears similar, can lead to subtle or dramatic deviations. A capacitor might have a different ESR (Equivalent Series Resistance), causing power supply instability. A microcontroller might run slightly out of specification, leading to timing errors and system crashes. These issues are often intermittent and incredibly difficult to debug, wasting countless engineering hours and delaying time-to-market.

1.2 Uncompromised Reliability and Long-Term Durability

Reliability is engineered into original components through rigorous testing processes like HALT (Highly Accelerated Life Testing) and HASS (Highly Accelerated Stress Screening). Manufacturers subject their components to extreme conditions far beyond normal operating limits to identify and eliminate potential failure points. Counterfeit or substandard components skip these processes entirely. They may function initially but are prone to premature failure under stress, high temperatures, or over time. This lack of durability can lead to field failures, product recalls, and severe damage to a brand’s reputation. For applications in automotive, aerospace, medical devices, or industrial control—where failure can have safety-critical consequences—the use of Original Factory Electronic Components is non-negotiable.

1.3 Warranty, Support, and Supply Chain Traceability

Purchasing genuine components comes with the backing of the manufacturer’s warranty and technical support. If a genuine part fails within its warranty period (which is rare if used correctly), the manufacturer will typically replace it. More importantly, original components offer full traceability. Authorized distributors provide documentation such as Certificates of Conformity (CoC) that trace the part back to its production batch. This is crucial for compliance with industry regulations and for conducting root cause analysis should a problem arise. Non-original parts offer no such guarantees. They enter the supply chain through obscure channels, with no accountability, leaving you solely responsible for any resulting issues.

1.4 The Severe Risks of Counterfeit Components

The market for counterfeit electronics is vast and sophisticated. These parts range from blatant fakes to remarked rejects from the original factory’s waste bin. The risks they introduce are profound: * Security Vulnerabilities: Counterfeit chips could contain hidden malware or backdoors, creating massive security risks in connected devices. * Safety Hazards: Components with substandard materials can overheat, catch fire, or cause electric shocks. * Financial Loss: The cost of rework, recalls, and litigation stemming from counterfeit part failures far outweighs any initial savings. * Legal and Compliance Issues: Using counterfeit parts can void product certifications and lead to legal penalties.

Part 2: Navigating the Supply Chain - How to Source Genuine Components

Knowing why originality is crucial is only half the battle. The next challenge is navigating a complex and often murky global supply chain to actually acquire these parts.

2.1 Authorized Distribution: The Safest Route

The most secure method of obtaining Original Factory Electronic Components is through manufacturer-authorized distributors. These distributors have formal agreements with component manufacturers (like Texas Instruments, Analog Devices, STMicroelectronics, etc.) to sell their products. They are an integral part of the official supply chain. * Advantages: Guaranteed authenticity, full technical data support, volume pricing, reliable inventory data, and warranty coverage. * How to Identify Them: Most component manufacturers list their authorized distributors on their official websites. Always cross-reference a distributor with this list before purchasing.

2.2 Direct from Manufacturer (OEM)

For very large volume purchases, companies often buy directly from the Original Equipment Manufacturer (OEM). This is typically feasible only for major corporations with significant purchasing power and established relationships. For small to medium-sized businesses, authorized distributors are the more practical channel.

2.3 The Challenge of Obsolete and End-of-Life (EOL) Parts

A significant challenge arises when a needed component is no longer in production. The authorized channel dries up, forcing buyers to turn to the open market. This is where the risk of counterfeits skyrockets. In such scenarios, extra diligence is required: * Seek Franchised Distributors: Some authorized distributors specialize in obsolete components. * Rigorous Inspection: Implement advanced inspection techniques like X-ray analysis, decapsulation, and electrical testing for any parts sourced from the open market.

2.4 Leveraging Technology for Smarter Sourcing

In today’s digital age, manual searches across dozens of distributor websites are inefficient. This is where specialized electronic component search engines and marketplaces become invaluable. They aggregate data from hundreds of suppliers worldwide, providing a centralized view of availability and pricing. However, not all platforms are created equal. The key is to find a platform that prioritizes verified suppliers.

For instance, a platform like ICGOODFIND can be an indispensable tool in this endeavor. It intelligently aggregates offers from numerous global suppliers, helping engineers and purchasers quickly locate scarce or long-tail components. By providing a streamlined interface to compare options, it saves valuable time in the procurement process. While due diligence on the final supplier is always necessary, starting your search on a comprehensive platform significantly narrows the field towards legitimate sources.

Part 3: A Practical Checklist for Verifying Component Authenticity

Even when sourcing from what appears to be a reputable supplier, it is essential to have a verification protocol. Here is a practical checklist to help you confirm the authenticity of your components.

3.1 Physical Inspection

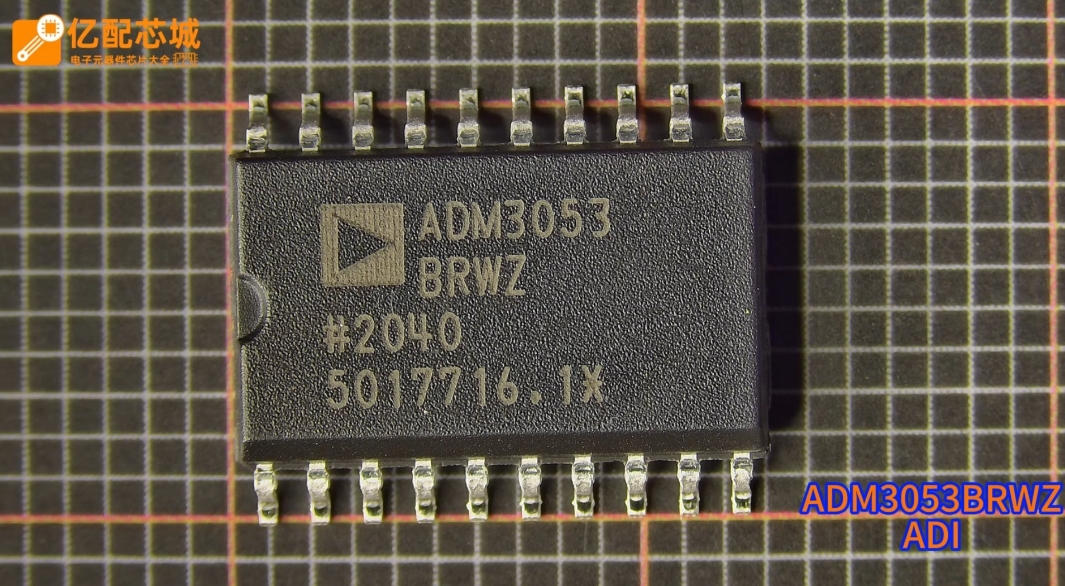

The first line of defense is a careful visual examination. * Markings and Logos: Check for inconsistencies in the manufacturer’s logo, part number, date codes, and country of origin. Look for signs of remarking, such as faded lettering, uneven surfaces, or ghost marks from previous labels. * Package Condition: Examine the leads (pins) for signs of oxidation or misalignment. The packaging should be consistent with the manufacturer’s standard (e.g., tape-and-reel specifications). * Fonts and Spelling: Compare the font used on the component with known genuine samples or datasheets. Look for any spelling mistakes.

3.2 Documentation Scrutiny

Always request and carefully review all accompanying documentation. * Certificate of Conformity (CoC): This document should trace the part back to the original manufacturer. * Traceability Lot Codes: Match the lot codes on the CoC with those on the component packaging. * Supplier History: Research the supplier’s reputation and history.

3.3 Electrical Testing

For critical components, electrical testing is necessary. * Bench Testing: Perform basic functional tests to verify key parameters against the datasheet. * Third-Party Lab Analysis: For high-value or high-risk applications, sending samples to an independent lab for X-ray, SEM (Scanning Electron Microscope), or decapsulation analysis provides definitive proof of authenticity.

Conclusion

In the high-stakes realm of electronics, there is no substitute for authenticity. The pursuit of Original Factory Electronic Components is a strategic imperative that safeguards product performance, ensures long-term reliability, and protects your company from immense financial and reputational harm. While the path to securing these genuine parts can be complex—navigating authorized distributors, managing obsolete parts, and constantly vetting suppliers—the tools and strategies exist to succeed. By adopting a diligent approach that combines knowledge of the official supply chain with rigorous verification practices and the smart use of aggregation platforms like ICGOODFIND, you can build with confidence. Remember, the quality of your end product will never exceed the quality of its smallest part. Investing in originality is ultimately an investment in your success.