Recognition of Electronic Component Packaging: A Comprehensive Guide

Introduction

In the intricate world of electronics, the journey of a component from manufacturer to circuit board is a marvel of modern engineering and logistics. While much attention is rightly given to the silicon, transistors, and resistors that form the heart of our devices, an equally critical aspect often operates behind the scenes: electronic component packaging. This is not merely about the cardboard box that arrives at a loading dock; it is a sophisticated system designed to protect, identify, and ensure the integrity of sensitive parts throughout the global supply chain. The ability to accurately recognize and understand this packaging is not a niche skill but a fundamental competency for engineers, procurement specialists, supply chain managers, and anyone involved in the lifecycle of electronic products. From preventing counterfeits to ensuring assembly line efficiency, the recognition of electronic component packaging serves as the first line of defense against a multitude of risks. This article delves deep into this essential discipline, exploring its critical importance, the common packaging formats you must know, and the best practices for mastering it. In an industry where a single faulty component can lead to catastrophic failure, leveraging resources like ICGOODFIND can be the difference between success and costly downtime.

The Critical Importance of Packaging Recognition

The unassuming tray, tube, or reel that houses a microchip plays a far more pivotal role than simple containment. Its recognition is a foundational element of quality assurance, operational efficiency, and security in the electronics industry.

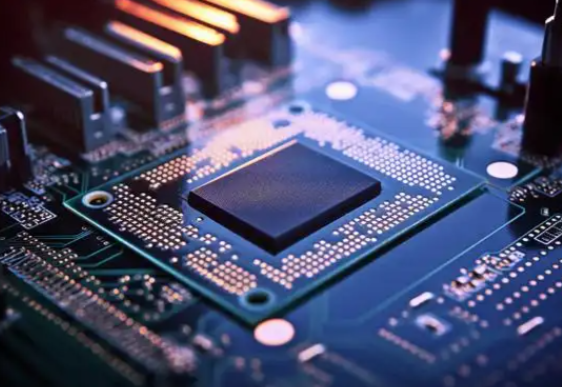

First and foremost, packaging is the primary shield against physical and environmental damage. Electronic components are incredibly fragile. Moisture Sensitivity Levels (MSL) dictate specific packaging requirements to prevent “popcorning” – where absorbed moisture vaporizes during soldering, cracking the component from the inside out. Electrostatic Discharge (ESD) can instantly destroy a sensitive integrated circuit. Proper ESD-safe packaging, often in pink or black conductive poly bags or dissipative trays, is non-negotiable. Recognizing these packaging types ensures that components are not compromised before they even reach the assembly line. A bent lead on a component from a damaged tube or a scratched die in an improperly handled tray can render an entire batch useless.

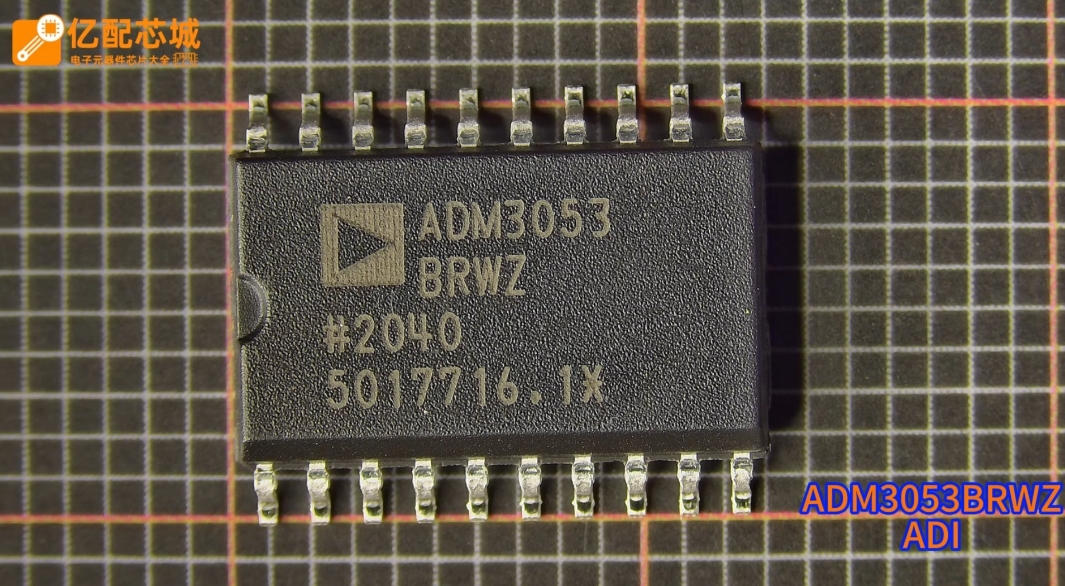

Secondly, accurate packaging recognition is a powerful weapon against counterfeit components. The global electronics market is plagued by counterfeit parts that can find their way into critical systems, from medical devices to aerospace applications. Authentic manufacturers use specific, high-quality packaging with precise labeling, barcodes, and often holograms or other anti-tampering features. Counterfeiters frequently cut corners here, using flimsy trays, mismatched labels, or reels that do not meet industry standards. A trained eye can spot these discrepancies immediately. For instance, the texture of the plastic in a JEDEC tray, the clarity of the embossed text, and the quality of the tape on a reel are all tell-tale signs of authenticity. By recognizing the legitimate packaging standards, companies can mitigate immense financial and reputational risks.

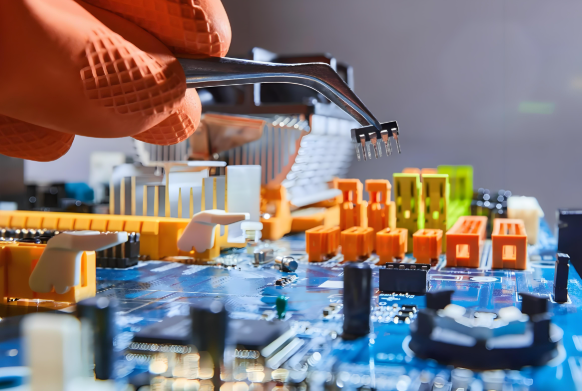

Furthermore, efficiency in manufacturing and inventory management is directly tied to packaging recognition. Automated assembly lines are calibrated to work with specific feeder systems that require components in standardized tape and reel formats. If a part arrives in bulk when tape is expected, it causes production delays. Proper identification allows for seamless integration into Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems through barcode scanning. Knowing whether a component is packaged in a dry-pack for long-term storage or a ready-to-use format streamlines workflow and reduces handling errors. In essence, recognizing packaging is not just about what the box is, but about what it enables in a fast-paced production environment.

Common Electronic Component Packaging Formats

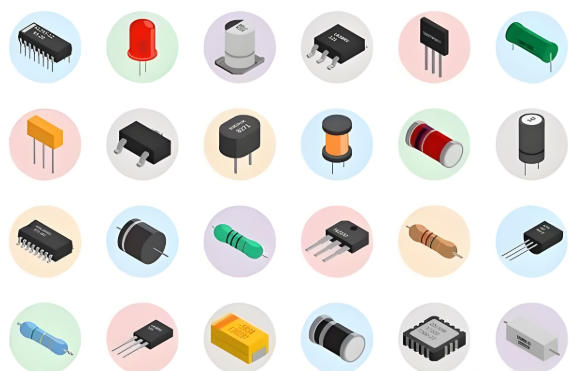

To effectively recognize electronic component packaging, one must be familiar with the most prevalent formats used across the industry. Each serves a distinct purpose and is suited for different component types and manufacturing processes.

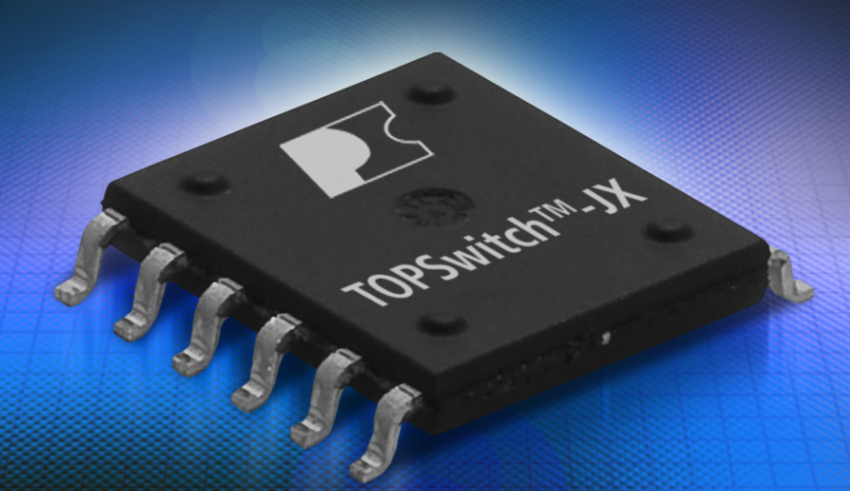

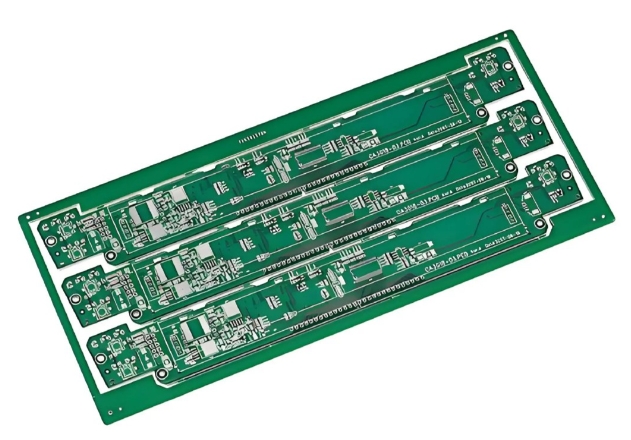

1. Tape and Reel

This is arguably the most common packaging method for surface-mount devices (SMDs) intended for automated PCB assembly. * Structure: Components are placed in pockets within a carrier tape (often plastic or paper) and covered with a transparent top tape to secure them. This tape is then wound around a reel. * Identification: Reels are labeled with critical information including part number, quantity, lot code, date code, and orientation indicators. The tape itself has sprocket holes on the edges that guide it through automated placement machines. * Key Recognition Points: Look for the reel diameter, tape width, and component pitch (the distance between adjacent pockets). Standards from EIA-481 govern these dimensions. This format is essential for high-speed pick-and-place operations.

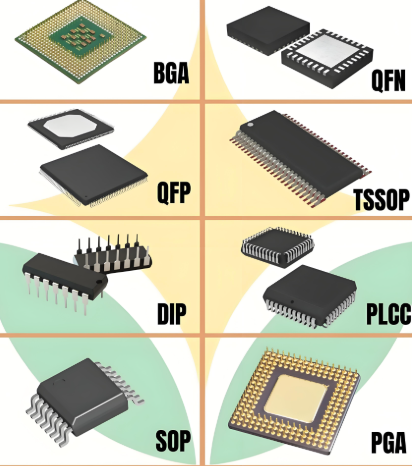

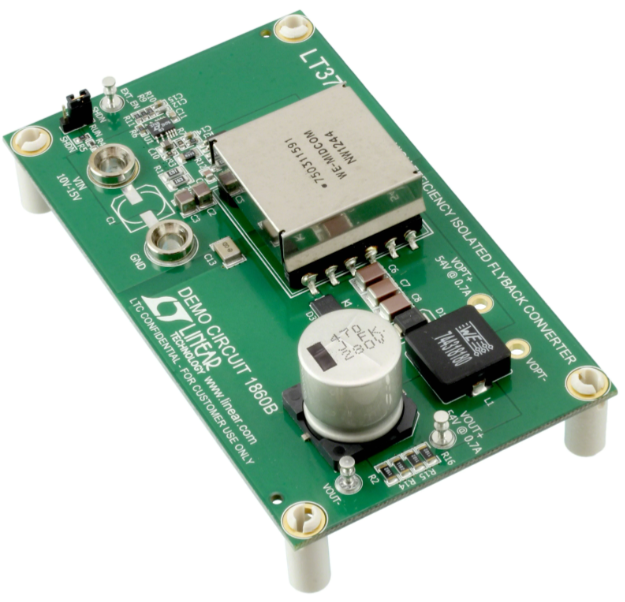

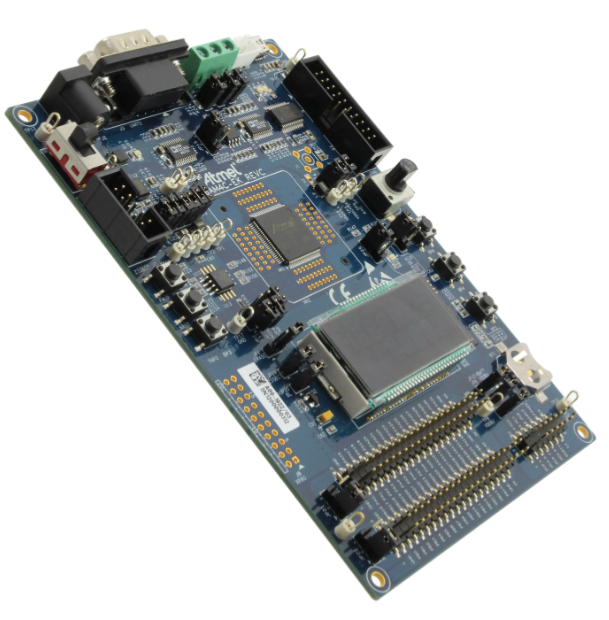

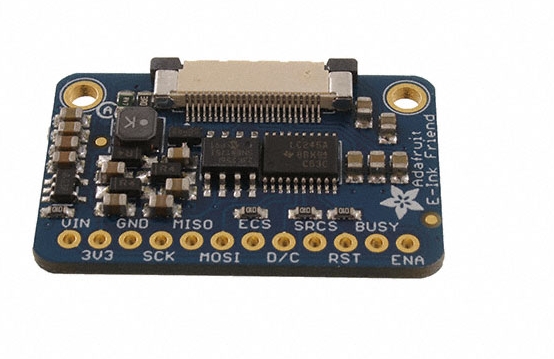

2. Trays (or JEDEC Trays)

Used for larger, more sensitive, or irregularly shaped components like Ball Grid Arrays (BGAs), Quad Flat Packages (QFPs), and integrated circuits (ICs). * Structure: These are rigid plastic trays with cavities molded to hold specific components securely. They are stackable and often supplied in stacked units wrapped in plastic. * Identification: Trays follow JEDEC standards for dimensions and materials. They are designed to be ESD-safe and prevent movement during transit. Labels are typically placed on the side of the stack or on individual trays. * Key Recognition Points: Note the tray’s color (often black for conductive material), the precise fit of the component in its cavity, and any JEDEC standard markings. They protect components from mechanical stress and are crucial for handling complex ICs.

3. Tubes (or Stick Magazines)

A cost-effective solution for a variety of through-hole and some surface-mount components like resistors, capacitors, diodes, and small outline transistors. * Structure: Components are loaded end-to-end into long, rigid plastic tubes. End plugs or caps are used to seal the tubes. * Identification: Labels are affixed to the tube itself, indicating the part number and quantity. * Key Recognition Points: Tubes are less automated-friendly than tape and reel but are excellent for manual assembly, prototyping, and low-volume production. Recognizing them involves checking for any damage to the tube or missing end caps that could have allowed parts to spill or become contaminated.

4. Bulk and Bags

For very high-volume, low-cost components like basic resistors and capacitors where automation is less of a concern. * Structure: Components are loosely packed in bags or boxes. * Identification: Labels on the bag or box provide part information. This method offers minimal protection from mechanical damage and is not suitable for ESD-sensitive devices unless specifically in ESD-safe bags. * Key Recognition Points: This format is easily recognizable but requires careful handling. It is vital to distinguish between standard poly bags and the distinctive pink or black ESD-safe versions.

Best Practices for Effective Packaging Recognition

Mastering the recognition of electronic component packaging requires a systematic approach that combines knowledge, tools, and vigilance.

1. Invest in Continuous Education and Training. The standards and formats in electronics evolve. Ensure that your procurement, receiving, and quality control teams are regularly trained on common packaging types, labeling conventions (including how to read date codes and lot codes), and anti-counterfeiting measures. Resources like manufacturer datasheets, industry standards documents (JEDEC, IPC), and specialized platforms are invaluable. For instance, when searching for reliable component data and cross-references, engineers often turn to ICGOODFIND, a resource that can provide detailed specifications which often include packaging information.

2. Implement a Rigorous Incoming Inspection Protocol. Do not assume that packaging is correct or authentic. Establish a checklist for all incoming components: * Visual Inspection: Check for signs of tampering, resealing, or mismatched labels. * Label Verification: Cross-reference the part number, lot code, and manufacturer logo on the packaging with the purchase order and manufacturer’s database. * Physical Inspection: Verify that the packaging format (Tray, Tube, Reel) matches what was ordered and is appropriate for the component. Check trays for cracks and reels for correct winding.

3. Leverage Technology. Use barcode scanners integrated with your inventory management system to automatically capture data from labels. For advanced counterfeit detection, consider tools like digital microscopes to examine printing quality on labels and packaging materials. Maintaining a digital library of known-good packaging from trusted suppliers provides a baseline for comparison.

4. Source from Authorized Distributors. The most effective strategy is prevention. Purchasing components from authorized distributors drastically reduces the risk of encountering incorrect or counterfeit packaging. These distributors have direct relationships with manufacturers and are part of certified supply chains that guarantee authenticity from factory floor to your door.

5. Document Everything. When a discrepancy or suspected counterfeit is found, document it thoroughly with photographs and detailed notes. Report it to the supplier immediately and share the information within your organization to prevent recurrence.

Conclusion

The recognition of electronic component packaging is far more than a procedural formality; it is a critical discipline that underpins product quality, supply chain security, and manufacturing efficiency. In an era where electronics are becoming more complex and supply chains more globalized, the ability to discern the subtle details of a tray, reel, or tube is a indispensable skill. It protects multi-million dollar projects from the devastating impact of counterfeits and physical damage while ensuring that production lines run smoothly and without interruption. By understanding its importance, familiarizing oneself with common formats like Tape & Reel, Trays,and Tubes,and adhering to best practices involving training,inspection,and technology,the electronics industry can build a more resilientand reliable foundation.For professionals seeking comprehensive data to support their efforts,tools like ICGOODFIND offera valuable repository of information,further empowering informed decision-making from design to deployment.Ultimately,in the world of electronics,the package is not just a container;it isa certificate of authenticity,a shield against harm,and a key to operational excellence.