Packaging of Common Electronic Components

Introduction

In the intricate world of electronics, the components that form the backbone of our devices—resistors, capacitors, integrated circuits (ICs), and more—are often celebrated for their functionality. However, their packaging, the physical enclosure that protects and connects them, is an equally critical aspect that dictates the performance, reliability, and manufacturability of the final product. The packaging of common electronic components is not merely a passive shell; it is a sophisticated interface between the delicate silicon die and the harsh real world. It provides mechanical support, environmental protection, and the crucial electrical connections that allow a component to function within a circuit. As technology advances towards smaller, faster, and more powerful devices, the evolution of component packaging has become a key driver of innovation. From the classic through-hole packages that defined early electronics to the ultra-miniature surface-mount packages enabling modern smartphones, understanding this landscape is essential for anyone involved in electronics design, procurement, or manufacturing. For professionals seeking reliable sources for these components across various package types, platforms like ICGOODFIND offer a streamlined gateway to a global network of suppliers, simplifying the procurement process.

The Evolution and Fundamentals of Electronic Component Packaging

The journey of electronic component packaging is a story of continuous miniaturization and performance enhancement. Initially, components like vacuum tubes were large and fragile. The invention of the transistor paved the way for smaller, more robust packages. The earliest widespread package types were Through-Hole Technology (THT) packages. Components like resistors, capacitors, and transistors were designed with long, sturdy leads that could be inserted through holes drilled in a printed circuit board (PCB) and soldered onto the opposite side. The most common THT packages include the Dual In-line Package (DIP) for integrated circuits and axial/radial leads for discrete components. THT packages are known for their strong mechanical bonds, making them ideal for prototypes, educational kits, and applications subject to high mechanical stress. However, their size and the need for drilled holes make them unsuitable for high-density, automated modern electronics.

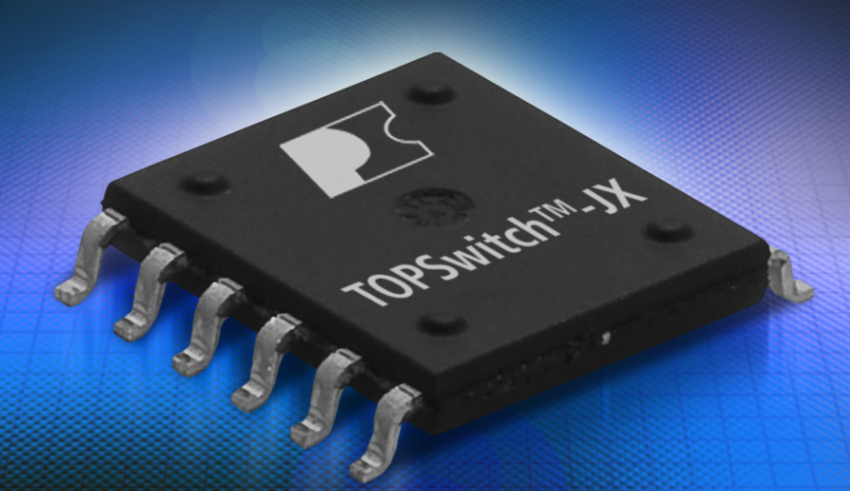

This limitation led to a revolutionary shift with the advent of Surface-Mount Technology (SMT). SMT components are designed with small metallic tabs or leads that are soldered directly onto the surface of the PCB. This eliminated the need for drilling holes, allowing components to be placed on both sides of the board and significantly increasing circuit density. The transition to SMT was a watershed moment, enabling the production of smaller, lighter, and faster electronic devices. SMT packages are categorized by their size and lead configuration. For integrated circuits, common SMT packages include Small Outline Integrated Circuit (SOIC), Quad Flat Package (QFP), and Ball Grid Array (BGA). For passive components like resistors and capacitors, standardized two-terminal packages such as 0402, 0603, and 0805 (indicating dimensions in mils) became the norm. The primary advantages of SMT are its suitability for full automation, higher component density, and better high-frequency performance due to reduced lead inductance.

Beyond the basic THT vs. SMT dichotomy, packaging serves several fundamental purposes that are non-negotiable for component reliability. First and foremost is Environmental Protection. The package seals the sensitive semiconductor die from potentially damaging elements like moisture, dust, chemicals, and accidental touch. Many packages are hermetically sealed to provide an absolute barrier. Secondly, packaging provides Mechanical Support and Thermal Management. The package structure anchors the delicate die and its internal bond wires, preventing damage from vibration or shock. Furthermore, it acts as a heat sink, dissipating the heat generated during operation away from the core silicon to prevent overheating. Materials with high thermal conductivity are often used in packages for high-power devices. Finally, the package enables Electrical Connection. It facilitates the fan-out of electrical connections from the densely spaced pads on the silicon die to the much wider pitch required for PCB soldering. The package leads or balls form the electrical bridge that integrates the component into the larger system.

A Detailed Look at Common Package Types

The universe of electronic component packages is vast and specialized. Understanding the characteristics of common packages is crucial for selecting the right component for a specific application.

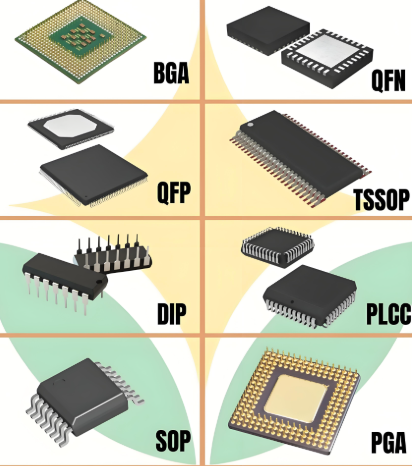

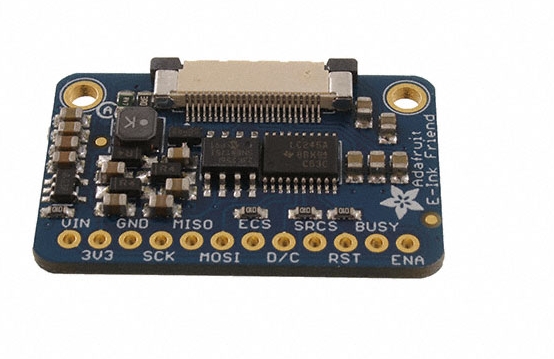

Integrated Circuit (IC) Packages: * Dual In-line Package (DIP): The classic through-hole package with two parallel rows of leads. It is easy to handle and prototype with but is largely obsolete in mass-produced consumer electronics. * Small Outline Integrated Circuit (SOIC): The surface-mount cousin of the DIP, offering a much smaller footprint. It is widely used for a broad range of common ICs. * Quad Flat Package (QFP): A surface-mount package with leads extending from all four sides. It allows for a high pin count in a relatively compact area. Variants include Thin QFP (TQFP) and Low-profile QFP (LQFP). * Ball Grid Array (BGA): A superior solution for high-pin-count and high-performance chips. Instead of peripheral leads, BGA packages have an array of solder balls on the bottom surface. This configuration offers excellent electrical performance, better thermal conduction, and a significantly smaller footprint compared to QFPs. However, BGA inspection and rework require specialized X-ray equipment, making the process more complex. * Chip-Scale Package (CSP): This package type is barely larger than the silicon die itself. It represents the cutting edge of miniaturization, commonly used in space-constrained devices like smartphones and wearables.

Discrete Component Packages: * Resistors & Capacitors: For through-hole technology, axial (leads on either end) and radial (leads protruding from one side) packages are standard. In surface-mount technology, they are almost universally found in rectangular Chip Packages like 0402, 0603, or 0805. * Transistors: Common through-hole packages include TO-92 for small-signal transistors and TO-220 for power transistors requiring a heat sink. Surface-mount equivalents are packages like SOT-23 (Small Outline Transistor) for signal applications and D²PAK (TO-263) for high-power applications. * Diodes: Similar to transistors, diodes use packages like DO-41 (through-hole axial) and SOD-123 (surface-mount).

Specialized and Advanced Packaging: As demands on performance and integration increase, advanced packaging techniques have emerged. System-in-Package (SiP) technology integrates multiple functional blocks—such as a processor, memory, and passive components—into a single package, creating a fully functional subsystem. This is different from a System-on-Chip (SoC), where all functions are on a single die. Another significant trend is 3D Packaging, where multiple silicon dies are stacked vertically and interconnected using through-silicon vias (TSVs), dramatically reducing interconnect length and improving speed and power efficiency.

The Critical Role of Packaging in Modern Electronics Design

Selecting the appropriate package is not an afterthought; it is a fundamental decision that influences every stage of product development.

Impact on PCB Design and Manufacturing: The choice of package directly dictates PCB layout complexity. A BGA component requires a sophisticated multi-layer board with carefully designed vias and traces to escape from under the component, while a SOIC or QFP is less demanding. Furthermore, assembly processes are entirely dependent on package type. Through-hole components require manual or wave soldering, whereas surface-mount components are placed by high-speed pick-and-place machines and soldered in reflow ovens.

Performance and Reliability Considerations: Electrical performance is heavily influenced by packaging. As signal frequencies increase into the gigahertz range, parasitic effects like capacitance and inductance from package leads become significant bottlenecks. Packages with shorter leads or leadless designs, such as BGAs or QFNs (Quad Flat No-leads), offer superior high-frequency performance. Thermal performance is another critical factor; a power-hungry IC in an inadequate package will overheat and fail prematurely.

Supply Chain and Sourcing Implications: Package selection also has major supply chain ramifications. Obsolete or uncommon package types can be difficult or expensive to source. Standardized surface-mount packages are generally more readily available and cost-effective due to economies of scale in their production. When navigating this complex global supply chain to find specific components in required packages efficiently turning to specialized search engines can be invaluable; this is where platforms like ICGOODFIND demonstrate their utility by aggregating real-time inventory data from numerous verified suppliers worldwide.

Conclusion

The packaging of common electronic components is a dynamic and deeply technical field that sits at the intersection of materials science, electrical engineering, and manufacturing logistics. It has evolved from simple protective casings to highly engineered systems that are integral to the performance and feasibility of modern electronics. From robust through-hole packages to dense BGAs and miniaturized CSPs each package type offers a unique set of trade-offs between size cost performance and manufacturability A thorough understanding of these options empowers designers to make informed decisions that optimize their products for success in a competitive market As technology continues its relentless march forward pushing the boundaries of what is possible advanced packaging solutions like 3D integration will undoubtedly play an even more pivotal role in shaping the future of electronics