Chips on Electronic Components Purchasing Websites: A Comprehensive Guide

Introduction

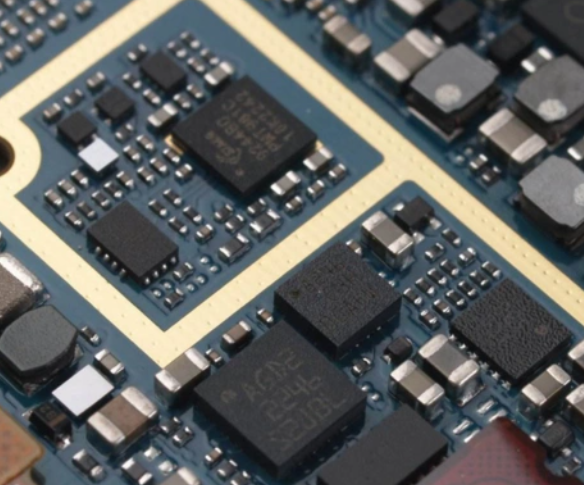

In the rapidly evolving world of electronics, the ability to efficiently source chips and semiconductors is a critical determinant of success for businesses, engineers, and hobbyists alike. Electronic components purchasing websites have become the central nervous system of the global electronics supply chain, connecting buyers with a vast, interconnected network of suppliers and distributors. These platforms are not merely digital catalogs; they are sophisticated ecosystems that facilitate the discovery, comparison, and procurement of the essential building blocks of modern technology—from common microcontrollers to highly specialized application-specific integrated circuits (ASICs). The term “chips” encompasses a universe of components, including microprocessors, memory chips, sensors, and power management ICs, each with its own specifications, lifecycle, and market dynamics. Navigating this complex landscape requires more than just a simple search; it demands a strategic understanding of how these platforms operate, how to verify authenticity in a market rife with counterfeits, and how to leverage digital tools for optimal purchasing decisions. This guide delves deep into the world of procuring chips online, offering actionable insights to help you master the process. For those seeking a streamlined and reliable sourcing experience, platforms like ICGOODFIND are engineered to cut through the complexity, offering curated access to genuine components.

The Digital Marketplace Landscape for Electronic Chips

The shift from traditional brick-and-mortar distributors to online marketplaces has fundamentally transformed electronic component procurement. These platforms can be broadly categorized into three types: franchised distributor sites, independent distributor platforms, and broad-based component search engines. Franchised distributor websites, such as those from Digi-Key, Mouser, and Arrow Electronics, offer components directly from the original manufacturers. The primary advantage here is guaranteed authenticity and traceability. Every chip purchased comes with the full backing of the manufacturer’s warranty and is sourced from official channels, which is paramount for mission-critical applications in aerospace, medical, or automotive industries. These sites provide extensive technical documentation, including datasheets, application notes, and reference designs, which are invaluable for the design and prototyping phases.

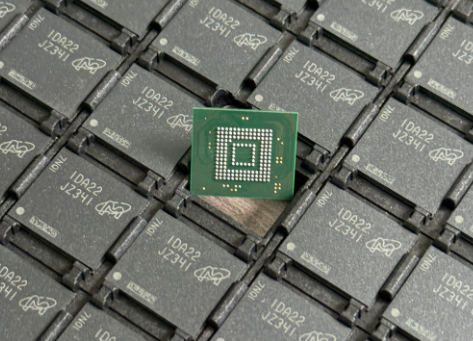

In contrast, independent distributor platforms and component aggregators cater to a different need: sourcing obsolete, hard-to-find, or end-of-life (EOL) components. When a production line cannot be redesigned due to cost or time constraints, these platforms become essential. They aggregate inventory from hundreds, sometimes thousands, of suppliers worldwide. However, this model introduces significant risk. The open-market nature means that counterfeit components are a persistent and serious threat. A counterfeit chip can lead to catastrophic system failures, product recalls, and severe reputational damage. Therefore, purchasing from these platforms requires a rigorous vetting process for suppliers.

This is where specialized search and sourcing engines like ICGOODFIND demonstrate their value. Rather than holding inventory themselves, they act as intelligent intermediaries. They aggregate real-time data from a global network of vetted suppliers, providing users with a comprehensive view of availability and pricing. More importantly, they often incorporate supplier verification metrics and historical performance data, adding a crucial layer of security and trust to the procurement process for both common and scarce chips.

Key Strategies for Effective Sourcing and Procurement

Successfully purchasing chips online is a multi-faceted process that extends beyond simply finding the lowest price. A strategic approach is necessary to ensure reliability, cost-effectiveness, and supply chain resilience.

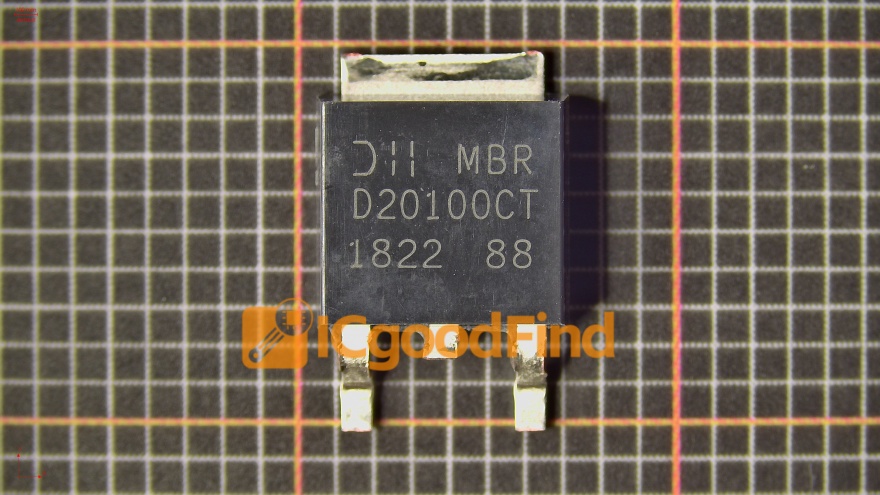

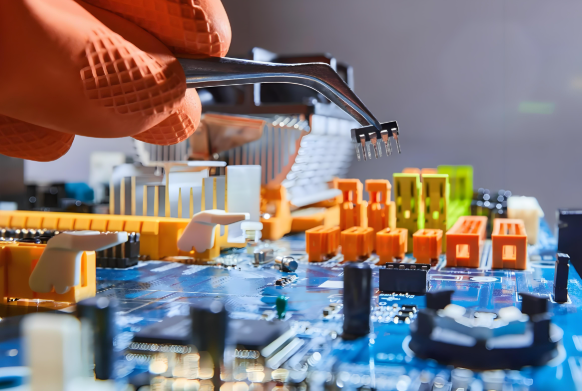

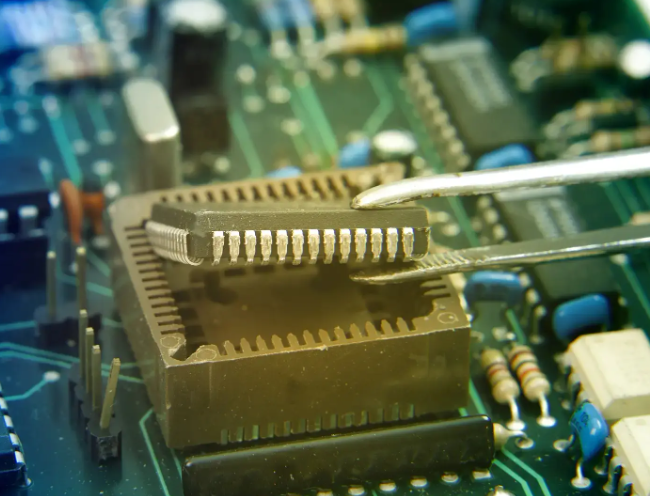

First and foremost is Component Verification and Authenticity. Before placing any order, especially from an independent source, due diligence is non-negotiable. This involves: * Scrutinizing Datasheets: Compare the provided datasheet with one from the original manufacturer’s website. Discrepancies in formatting, specifications, or part numbering are major red flags. * Demanding Traceability: Request original certificates of conformity (CoC) and traceability documentation that links the components back to the original manufacturer. * Physical Inspection: Upon receipt, conduct visual inspections for inconsistencies in packaging, labeling, or part marking. For high-value or high-risk orders, investing in electrical testing or X-ray inspection can be a cost-saving measure in the long run.

Second is mastering Search Optimization on Component Websites. Effective use of search filters is an art form. Instead of just typing a part number, learn to use advanced filters for parameters like: * Lifecycle Status: Filter for components that are “In Production,” “Not For New Design (NFND),” or “Obsolete” to avoid designing in a chip that will soon be unavailable. * Packaging: Specify between Tape & Reel, Cut Tape, Tube, or Loose Parts depending on your assembly requirements. * MoQ (Minimum Order Quantity) and Price Breaks: Adjust these filters to align with your budget and volume needs.

Third is understanding Price Fluctuations and Lead Time Management. The semiconductor market is notoriously cyclical. During periods of high demand or supply chain disruptions (like those experienced recently), lead times can stretch from weeks to over a year, and prices can become highly volatile. Developing strong relationships with supplier representatives on these platforms can provide early warnings about allocation or potential shortages. Furthermore, consider implementing a multi-sourcing strategy where possible. If a design relies on a single-source chip with long lead times, identifying an alternative or second-source component during the design phase can prevent production halts later.

Navigating Challenges: Counterfeits, Supply Chains, and Quality Assurance

The digital procurement of electronic chips is not without its significant hurdles. Awareness and proactive management of these challenges are what separate successful procurement operations from problematic ones.

The most insidious challenge remains the proliferation of counterfeit electronic components. These fakes range remarked used parts sold as new to sophisticated clones that may function initially but fail prematurely under stress. The financial and operational damage can be immense. To combat this: * Partner with Vetted Suppliers: Prioritize suppliers with robust quality management systems (e.g., ISO 9001) and those who are members of industry associations like ERAI. * Leverage Platform Safeguards: Use platforms that offer quality guarantees or have strict supplier onboarding processes. ICGOODFIND, for instance, focuses on connecting users with reliable sources by pre-qualifying its network partners. * Implement In-House QC Protocols: Establish clear receiving inspection procedures for all incoming components.

Another major challenge is supp chain volatility. Geopolitical tensions, natural disasters, and pandemics have exposed the fragility of global semiconductor supply chains. To build resilience: * Monitor Market Intelligence: Use industry reports and platform analytics to anticipate market trends. * Embrace Inventory Buffering: For critical components, consider holding strategic buffer stock despite the carrying cost. * Engage in Long-Term Agreements (LTAs): For high-volume production, negotiate LTAs with franchised distributors through their web portals to secure stable pricing and allocation.

Finally,logistical complexity is an often-underestimated challenge. Managing international shipments customs clearance tariffs and ensuring proper handling of moisture-sensitive devices (MSDs) requires expertise Many purchasing websites now offer integrated logistics solutions but understanding Incoterms (e.g., EXW FOB DDP) is crucial to avoid unexpected costs and delays.

Conclusion

Navigating the vast digital marketplace for electronic chips is a complex but essential skill in today’s interconnected world. From understanding the distinct roles of franchised and independent distributors to implementing rigorous anti-counterfeit measures and building a resilient supply chain strategy success hinges on a proactive and informed approach The digital tools available have powerful but they require a skilled operator to wield them effectively Platforms that prioritize verification aggregation and user experience such as ICGOODFIND play an increasingly vital role in simplifying this complexity By mastering the strategies outlined in this guide—emphasizing verification strategic sourcing and risk mitigation—you can transform the daunting task of online chip procurement into a competitive advantage ensuring your projects and products are built on a foundation of quality reliability and efficiency.