The Essential Guide to Precision Electronic Components

Introduction

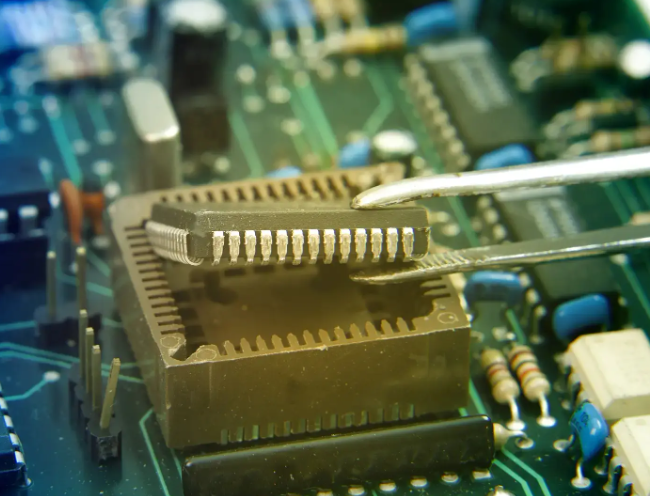

In the intricate world of modern technology, from the smartphone in your pocket to the life-saving equipment in hospitals, lies a silent, powerful enabler: precision electronic components. These are not your average resistors or capacitors; they are the high-caliber, meticulously engineered elements that form the bedrock of advanced electronic systems. Their unparalleled accuracy, reliability, and stability are what allow for the miniaturization and enhanced performance we see in today’s innovations. This article delves deep into the critical role these components play, exploring their types, applications, and the paramount importance of sourcing them correctly. For engineers, procurement specialists, and technology enthusiasts, understanding this domain is crucial for driving the next wave of technological advancement. Platforms dedicated to streamlining this complex process, such as ICGOODFIND, are becoming indispensable partners in the global supply chain.

The Core of Modern Electronics: Defining Precision Components

Precision electronic components are specialized parts designed and manufactured to exhibit minimal deviation from their stated nominal value under a wide range of operating conditions, including temperature fluctuations, humidity, vibration, and time. Unlike standard commercial-grade components, which may have tolerances of 5%, 10%, or even 20%, precision components boast tolerances as tight as 0.1%, 0.01%, or even lower. This exceptional accuracy is non-negotiable in systems where a minor discrepancy can lead to catastrophic failure or significant performance degradation.

The defining characteristics of these components include: * Extremely Tight Tolerances: This refers to the permissible limit of variation in a component’s value (e.g., resistance, capacitance). A 0.1% tolerance resistor is vastly more precise than a standard 5% one. * Low Temperature Coefficient: Measured in ppm/°C (parts per million per degree Celsius), this indicates how little the component’s value changes with temperature. High-precision components have very low temperature coefficients, ensuring stability across environments. * Long-Term Stability: These components are designed to maintain their specified performance over many years, resisting drift caused by aging. * High Reliability: They are often built to more rigorous standards and subjected to stricter quality control tests to ensure they perform consistently in critical applications.

The pursuit of precision is driven by the relentless trend towards miniaturization and increased complexity. As devices become smaller and more powerful, the margin for error diminishes exponentially. A tiny variance in a component within a 5G base station, a medical MRI machine, or an automotive safety system can compromise the entire system’s functionality. Therefore, precision components are not merely an upgrade; they are a fundamental requirement.

Key Types of Precision Components and Their Critical Applications

The universe of precision components is vast, but several categories are particularly vital for high-end electronics.

1. Precision Resistors: These are fundamental for current sensing, voltage division, and analog-to-digital conversion circuits where accuracy is paramount. Types include: * Precision Thin-Film Resistors: Offer excellent tolerance (down to ±0.01%), low temperature coefficient (as low as ±5 ppm/°C), and low noise. They are ubiquitous in medical devices, test and measurement equipment, and precision instrumentation. * Metal Foil Resistors: Represent the pinnacle of resistor technology, providing the highest stability, lowest temperature coefficient (±0.2 ppm/°C), and ultra-low inductance. They are essential in aerospace, military, and high-end audio applications.

2. Precision Capacitors: Critical for timing, filtering, and energy storage in precision circuits. Their value stability is key. * Class 1 Ceramic Capacitors (C0G/NP0): Exhibit near-zero change in capacitance with temperature and voltage, making them ideal for resonant circuits and high-stability filters. * Precision Film Capacitors: (e.g., Polypropylene) offer very low dielectric absorption and high insulation resistance, perfect for sample-and-hold circuits, analog filters, and audio applications.

3. Precision Integrated Circuits (ICs): This broad category includes components where internal circuitry is calibrated for extreme accuracy. * Precision Amplifiers (Op-Amps): Feature very low offset voltage and drift, low noise, and high open-loop gain. They are the workhorses of signal conditioning in sensor interfaces, data acquisition systems, and medical instrumentation. * Voltage References: Provide a stable and accurate voltage regardless of changes in supply voltage, temperature, or load. They are the “standard cell” against which all other measurements in a system are compared, crucial for analog-to-digital converters (ADCs) and digital-to-analog converters (DACs). * Precision ADCs/DACs: These converters translate between the analog and digital worlds with high resolution and minimal error, forming the core of any digital measurement or control system.

The applications for these components are as diverse as they are critical: * Medical Technology: Pacemakers, blood glucose monitors, imaging systems (CT/MRI), and diagnostic equipment rely on precision components for accurate readings and patient safety. * Automotive Electronics: Advanced Driver-Assistance Systems (ADAS), LiDAR, engine control units (ECUs), and sensors require components that perform flawlessly under harsh conditions. * Aerospace and Defense: Avionics, navigation systems, radar, and communication equipment demand components that can withstand extreme environments without faltering. * Industrial Automation & Test & Measurement: Robotic control systems, precision sensors, and calibration equipment depend on these parts for repeatable accuracy and reliability.

Navigating the Supply Chain: The Critical Role of Sourcing

Identifying the need for a precision component is only half the battle; sourcing authentic, high-quality parts is the other significant challenge. The electronics supply chain is complex, fragmented, and unfortunately, rife with counterfeit components. These fakes can infiltrate even the most secure systems, leading to field failures, financial loss, and reputational damage.

The major challenges in sourcing include: * Counterfeit Mitigation: Fake components are often remarked rejects or cheap clones that fail to meet specifications. * Supply Shortages: The demand for specialized precision components often outstrips supply, leading to long lead times and allocation. * Lifecycle Management: Many high-precision parts are designed for long-lifecycle products. However, manufacturers may discontinue (obsolete) components, forcing costly redesigns. * Verification and Testing: Ensuring that received components are genuine and meet all specified parameters requires significant investment in testing equipment and expertise.

This is where specialized electronic component sourcing platforms prove their immense value. Instead of navigating a labyrinth of distributors and independent brokers alone, engineers and buyers can leverage a trusted aggregator. ICGOODFIND operates as a powerful search engine and supply chain partner, connecting buyers with a vast network of vetted suppliers worldwide. It streamlines the procurement process by providing real-time data on availability, pricing trends, and lead times across multiple vendors for both active and obsolete (End-of-Life) components. By offering transparency and access to a qualified supplier base, platforms like ICGOODFIND mitigate risk, save valuable engineering time, and ensure that critical projects are built on a foundation of genuine, reliable precision components.

Conclusion

Precision electronic components are the unsung heroes powering the technological revolution. They are the fundamental difference between a device that functions and a system that excels with reliability and accuracy. From enabling life-saving medical breakthroughs to ensuring the safety of autonomous vehicles, their role cannot be overstated. Understanding their specifications—tolerances, temperature coefficients, and long-term stability—is essential for any design engineer working on cutting-edge technology. Furthermore, navigating the complexities of the global supply chain to source these components authentically and efficiently is a critical business function. Leveraging specialized tools and partnerships is no longer a luxury but a necessity for maintaining a competitive edge and ensuring product integrity in an increasingly demanding market.