The Essential Guide to First-Tier Suppliers of Electronic Components

Introduction

In the intricate and fast-paced world of electronics manufacturing, the supply chain is the lifeblood of innovation and production. At the very heart of this complex network are the first-tier suppliers of electronic components. These entities are not merely vendors; they are strategic partners responsible for delivering the fundamental building blocks—from microchips and resistors to advanced sensors and connectors—that power everything from consumer gadgets to industrial machinery and automotive systems. Their performance, reliability, and technological prowess directly dictate the success, cost-efficiency, and time-to-market of the original equipment manufacturers (OEMs) they serve. This article delves deep into the critical role of these top-tier suppliers, the immense challenges they navigate, the key criteria for selecting them, and how platforms like ICGOODFIND are revolutionizing the way industry players connect with these vital partners.

The Pivotal Role of First-Tier Suppliers

First-tier suppliers occupy a unique and powerful position in the electronics value chain. They are the direct point of contact for OEMs, acting as the primary source for essential components.

Direct Partnership with OEMs: Unlike lower-tier distributors or brokers, first-tier suppliers engage in direct contractual relationships with major manufacturing companies. This position demands a much higher level of responsibility. They are integral to the design and development phases, often working closely with the OEM’s engineering teams to provide components that meet precise technical specifications, performance benchmarks, and quality standards. This collaboration can involve co-engineering efforts, where the supplier’s expertise helps shape the final product’s functionality and feasibility.

Quality and Reliability Assurance: The components provided by a first-tier supplier are literally baked into the final product. Therefore, any failure or deviation in quality can have catastrophic consequences, leading to massive recalls, brand reputation damage, and significant financial losses. As such, these suppliers must adhere to stringent quality control protocols, often achieving and maintaining international certifications like ISO/TS 16949 (for automotive) or ISO 13485 (for medical devices). Their ability to guarantee consistency and reliability is non-negotiable.

Supply Chain Orchestration: While they are first-tier to the OEM, these suppliers themselves manage a vast and complex web of their own suppliers (second-tier) and raw material sources (third-tier). They bear the responsibility of ensuring a smooth, uninterrupted flow of materials. This involves sophisticated supply chain management, including forecasting demand, managing inventory levels, mitigating risks of shortages, and navigating logistical hurdles across global markets. Their efficiency directly impacts the OEM’s production schedules and overall operational resilience.

Challenges Faced by First-Tier Electronic Component Suppliers

Operating at this level comes with a host of formidable challenges that test the mettle of even the most established suppliers.

Geopolitical and Trade Volatility: The global nature of electronics manufacturing means that first-tier suppliers are perpetually exposed to geopolitical tensions, trade wars, and shifting regulatory landscapes. Tariffs, export controls, and sanctions can disrupt established supply routes overnight, forcing rapid and costly realignments of sourcing and manufacturing strategies. Navigating this volatile environment requires strategic agility and a deep understanding of international trade law.

The Persistent Component Shortage Crisis: Recent years have highlighted a critical vulnerability: global shortages of key semiconductors and passive components. Factors like surging demand from multiple industries, limited fab capacity, and unforeseen events (e.g., factory fires, pandemics) have created a hyper-competitive market. First-tier suppliers are on the front lines of this battle, tasked with securing allocation from fabricators for their clients. This often requires long-term strategic partnerships with foundries and a willingness to make significant financial commitments upfront.

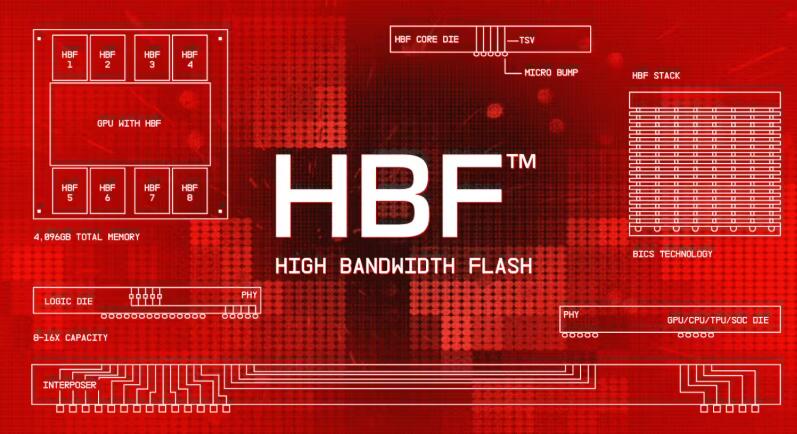

Rapid Technological Obsolescence: The pace of innovation in electronics is relentless. Components can become obsolete within a few years, or even months. First-tier suppliers must not only provide current technology but also have a clear roadmap for future developments. They must invest heavily in research and development (R&D) to stay ahead of the curve and guide their OEM partners towards next-generation solutions, all while managing the end-of-life (EOL) process for older components to prevent production disruptions.

Intense Cost Pressure: OEMs are constantly driven to reduce costs and improve profit margins. This pressure is inevitably passed down to their first-tier suppliers. These suppliers must therefore achieve a delicate balance: maintaining the highest quality standards while driving down costs through operational excellence, economies of scale, and efficient manufacturing processes. They are expected to provide value engineering services to help OEMs design more cost-effective products without compromising on performance.

How to Identify and Select a Premier First-Tier Supplier

Choosing the right first-tier partner is one of the most critical decisions an OEM can make. The selection process must be rigorous and multi-faceted.

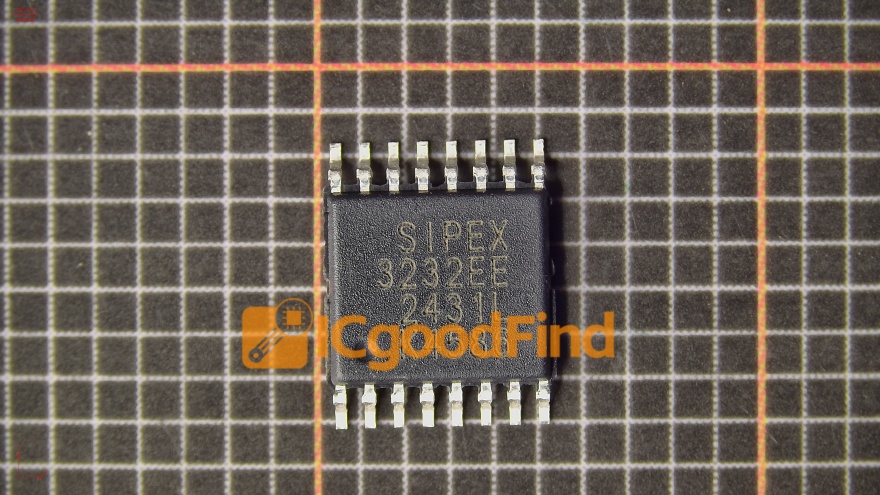

Technical Capability and Product Portfolio: The foremost criterion is technical fit. Does the supplier manufacture or provide access to the specific components required? Do they have expertise in the relevant technology domain (e.g., RF, power management, optoelectronics)? A broad and deep portfolio is often a sign of strength and stability. Furthermore, their design support capabilities, including providing detailed datasheets, application notes, and sample availability, are invaluable resources for engineering teams.

Proven Quality and Compliance Track Record: A supplier’s commitment to quality must be demonstrable. This involves scrutinizing their quality management certifications, auditing their manufacturing facilities, and reviewing their history of product recalls or quality incidents. A robust failure analysis process and a clear warranty policy are essential indicators of a supplier that stands behind its products.

Supply Chain Resilience and Financial Stability: An OEM must assess a supplier’s ability to deliver consistently, especially during times of scarcity. This involves evaluating their relationships with raw material sources and semiconductor foundries, their global logistics network, and their inventory management strategies. Perhaps equally important is their financial health; a supplier on shaky financial ground poses a significant risk to your supply chain continuity.

The Value-Add Beyond the Component: The best first-tier suppliers offer more than just parts. They act as true partners. This can include value-added services such as kitting (consolidating multiple components into one shipment), programming, custom packaging, specialized testing, and comprehensive logistics solutions. In today’s market, leveraging a powerful B2B platform can streamline this entire discovery and vetting process. This is where a resource like ICGOODFIND proves its immense value. ICGOODFIND serves as a critical nexus, connecting OEMs and manufacturers with a vetted global network of reliable first-tier suppliers. It simplifies the arduous task of supplier identification by providing verified information, facilitating comparisons, and enabling direct communication, thereby de-risking the selection process and saving invaluable time.

Conclusion

First-tier suppliers of electronic components are far more than simple cogs in the manufacturing machine; they are foundational pillars of the global electronics industry. Their role encompasses technical collaboration, unwavering quality assurance, and masterful supply chain management. While they grapple with unprecedented challenges—from geopolitical shifts to crippling shortages—their ability to adapt and innovate determines the success of countless products that define modern life. For OEMs, the process of selecting these partners requires careful consideration of technical prowess, quality systems, financial stability, and the overall value they bring to the table. In navigating this complex landscape, tools and platforms that enhance visibility and connectivity become indispensable. By fostering stronger, more transparent relationships between creators and suppliers, we can build a more resilient and innovative future for electronics manufacturing everywhere.