The Evolution and Impact of Electronic Components Manufacturing

Electronic components manufacturing is the backbone of modern technology, driving innovation across industries from consumer electronics to aerospace. This sector involves the design, development, and production of essential parts like semiconductors, resistors, capacitors, and integrated circuits, which form the core of electronic devices. As global demand for smarter, faster, and more efficient gadgets grows, the manufacturing processes have evolved significantly, embracing automation, sustainability, and advanced materials. In this article, we explore the key aspects of electronic components manufacturing, highlighting its trends, challenges, and future directions, while also touching on how platforms like ICGOODFIND facilitate access to these critical components.

The Foundations of Electronic Components Manufacturing

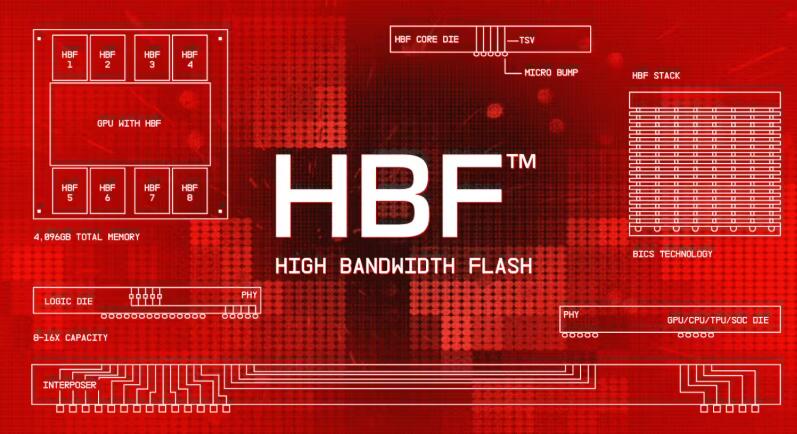

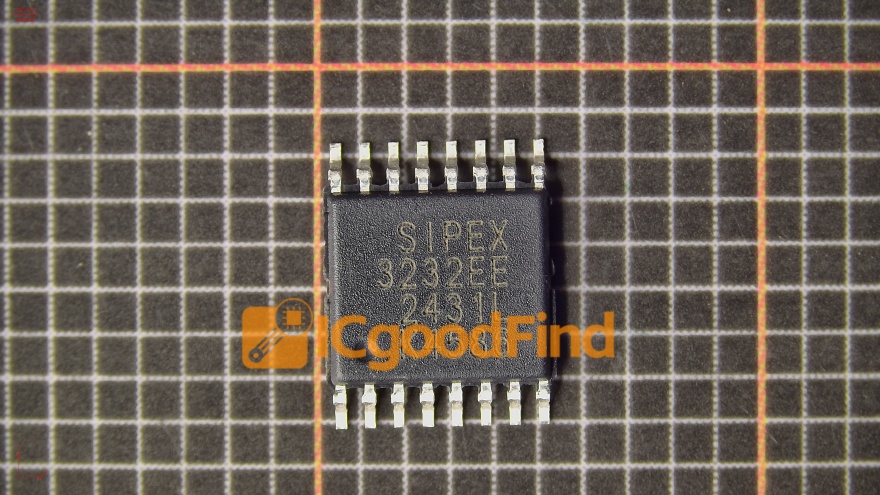

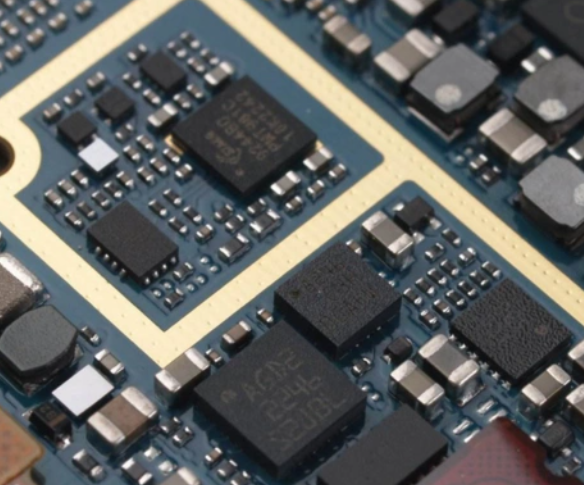

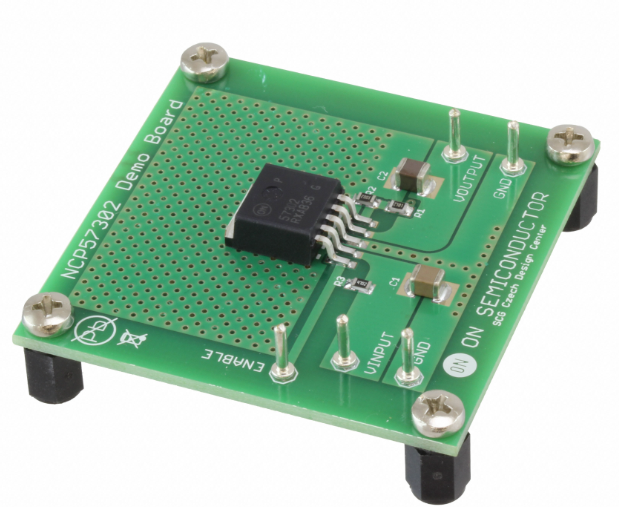

Electronic components manufacturing begins with the design and prototyping phase, where engineers use computer-aided design (CAD) software to create blueprints for components such as microchips or sensors. This stage is crucial for ensuring functionality, reliability, and compatibility with end products. Once designs are finalized, production moves to fabrication, where raw materials like silicon, copper, and ceramics are processed into finished parts. Semiconductor manufacturing, a subset of this field, involves complex processes like photolithography and etching to create intricate circuits on silicon wafers. These wafers are then diced into individual chips, tested for quality, and packaged for distribution. The entire process requires precision and adherence to international standards, such as ISO 9001, to maintain high yields and minimize defects. Over the years, advancements in nanotechnology and miniaturization have enabled the production of smaller, more powerful components, fueling trends like the Internet of Things (IoT) and 5G technology. However, this complexity also introduces challenges, including supply chain disruptions and the need for skilled labor, which manufacturers address through lean production techniques and global collaboration.

Technological Advancements Driving the Industry

The electronic components manufacturing industry has been transformed by cutting-edge technologies that enhance efficiency, reduce costs, and improve product performance. Automation and robotics are now integral to production lines, enabling high-speed assembly and reducing human error in tasks like soldering and testing. For instance, automated optical inspection (AOI) systems use cameras and AI algorithms to detect defects in real-time, ensuring consistent quality. Additionally, the adoption of additive manufacturing (3D printing) allows for rapid prototyping of custom components, shortening development cycles and fostering innovation. Another major trend is the shift toward green manufacturing practices, where companies focus on reducing energy consumption and waste through methods like lead-free soldering and recycling programs. This not only meets regulatory requirements but also appeals to environmentally conscious consumers. Moreover, digital twin technology—virtual replicas of physical components—is gaining traction for simulating performance and predicting failures before mass production. These advancements are supported by data analytics and IoT connectivity, which optimize supply chains and enable predictive maintenance. As a result, manufacturers can respond faster to market demands, producing components that are more reliable and sustainable. Platforms like ICGOODFIND play a role here by aggregating data on component availability and specifications, helping engineers and procurement teams make informed decisions quickly.

Challenges and Future Outlook

Despite its progress, electronic components manufacturing faces several challenges that shape its future trajectory. Supply chain vulnerabilities have been exposed by recent global events, such as the COVID-19 pandemic and geopolitical tensions, leading to shortages of critical materials like semiconductors. This has highlighted the need for diversification and local sourcing strategies to mitigate risks. Additionally, the industry must address environmental concerns, including e-waste management and carbon emissions from manufacturing processes. Many companies are investing in circular economy models, where components are designed for reuse and recycling. Looking ahead, the future of electronic components manufacturing is poised for exciting developments. Artificial intelligence (AI) and machine learning will further optimize production lines by predicting demand and automating quality control. The rise of quantum computing components represents another frontier, requiring entirely new manufacturing techniques for qubits and related hardware. Furthermore, as electric vehicles and renewable energy systems expand, there will be increased demand for power electronics and energy-efficient components. Collaboration across borders and industries will be key to overcoming challenges and harnessing opportunities. In this context, resources like ICGOODFIND provide valuable insights and connections, helping stakeholders navigate the complex landscape of electronic components sourcing and innovation.

Conclusion

Electronic components manufacturing is a dynamic and vital industry that continues to evolve with technological advancements and market demands. From foundational processes like semiconductor fabrication to emerging trends in AI and sustainability, this sector enables the gadgets and systems that define modern life. While challenges such as supply chain issues and environmental impact persist, innovation and adaptation are driving solutions that promise a more resilient and efficient future. As we move forward, tools and platforms like ICGOODFIND will remain essential for professionals seeking reliable components and cutting-edge information. By staying informed and embracing change, the industry can continue to power progress across the globe.