Navigating the World of Electronic Components Manufacturers

In today’s rapidly advancing technological landscape, electronic components serve as the fundamental building blocks of innovation. From smartphones and medical devices to automotive systems and industrial machinery, these tiny yet powerful parts are integral to the functionality of modern electronics. As demand for smarter, faster, and more efficient devices grows, the role of electronic components manufacturers becomes increasingly critical. These manufacturers are not only responsible for producing high-quality parts but also for driving research and development in areas like IoT, AI, and renewable energy. This article explores the key aspects of electronic components manufacturing, highlighting industry leaders, challenges, and future trends, while also emphasizing the importance of reliable sourcing platforms like ICGOODFIND in connecting businesses with top-tier suppliers.

The Role of Electronic Components Manufacturers in Global Technology

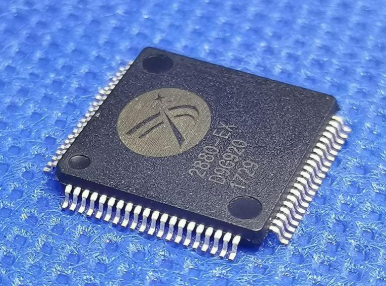

Electronic components manufacturers are the backbone of the global technology supply chain, producing essential parts such as semiconductors, resistors, capacitors, and integrated circuits. These components are used in virtually every electronic device, making manufacturers pivotal to industries like consumer electronics, healthcare, automotive, and aerospace. Leading manufacturers, such as Texas Instruments, Intel, and Samsung Electronics, invest heavily in research and development to create components that are smaller, more efficient, and capable of handling complex functions. For instance, the shift toward 5G technology has driven demand for advanced semiconductors that support higher data speeds and lower latency. Similarly, the automotive industry’s move toward electric vehicles (EVs) relies on manufacturers producing robust power management chips and sensors.

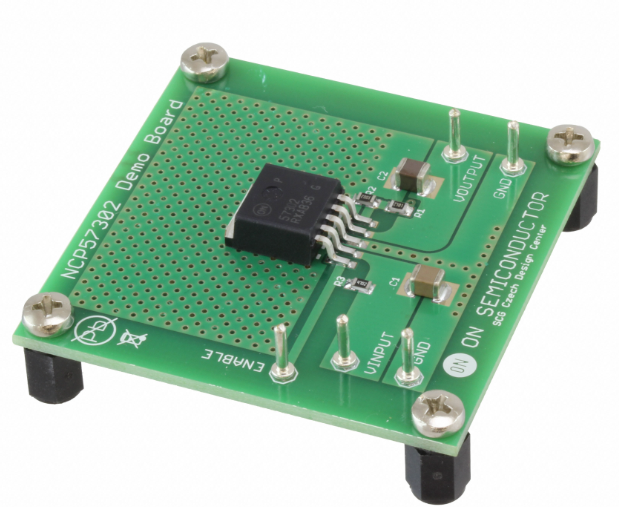

The manufacturing process itself is highly complex, involving precision engineering, stringent quality control, and adherence to international standards like ISO 9001. Manufacturers must balance cost-efficiency with innovation, often operating in a competitive global market where supply chain disruptions—such as those seen during the COVID-19 pandemic—can have far-reaching impacts. Additionally, sustainability has become a key focus, with many companies adopting green manufacturing practices to reduce electronic waste and carbon emissions. By leveraging automation and smart factory technologies, manufacturers are improving production efficiency while maintaining high quality. This sector’s growth is fueled by emerging trends like the Internet of Things (IoT), which requires billions of connected devices, and artificial intelligence (AI), which depends on specialized processors. As such, electronic components manufacturers are not just suppliers; they are enablers of technological progress.

Challenges Faced by Electronic Components Manufacturers

Despite their critical role, electronic components manufacturers face numerous challenges that can impact production and delivery. One of the most significant issues is supply chain volatility, which includes shortages of raw materials, logistical delays, and geopolitical tensions. The recent global chip shortage, exacerbated by increased demand for electronics and pandemic-related disruptions, highlighted how fragile the supply chain can be. Manufacturers must navigate these uncertainties by diversifying their supplier base and investing in resilient logistics networks. Another major challenge is technological obsolescence. With rapid advancements in electronics, components can become outdated quickly, forcing manufacturers to continuously innovate while managing inventory of older parts. This requires agile production systems and close collaboration with clients to forecast demand accurately.

Quality control is another hurdle, as defects in components can lead to failures in end products—potentially causing safety issues or recalls. Manufacturers implement rigorous testing protocols, including automated optical inspection (AOI) and environmental stress testing, to ensure reliability. However, maintaining these standards while keeping costs competitive is a constant struggle. Additionally, regulatory compliance adds complexity, especially with varying international standards for safety, emissions, and materials (e.g., RoHS and REACH directives). Cybersecurity is also a growing concern, as connected manufacturing systems are vulnerable to attacks that could disrupt operations or steal intellectual property. To address these challenges, many manufacturers are turning to digital transformation—using IoT sensors for predictive maintenance, AI for quality assurance, and blockchain for supply chain transparency. Despite these efforts, the industry must contend with a skilled labor shortage, particularly in engineering fields, necessitating investments in training and automation.

The Future of Electronic Components Manufacturing

The future of electronic components manufacturing is shaped by transformative trends that promise to redefine the industry. Artificial intelligence and machine learning are at the forefront, enabling smarter manufacturing processes that optimize production lines, reduce waste, and enhance quality control. AI-driven predictive maintenance can anticipate equipment failures before they occur, minimizing downtime. Another key trend is the adoption of additive manufacturing (3D printing), which allows for rapid prototyping and custom component production, reducing time-to-market for new designs. Sustainability will continue to be a priority, with manufacturers investing in circular economy models—recycling materials from old electronics and designing components for easier disassembly and reuse.

The rise of edge computing and 5G will drive demand for specialized components that support faster data processing and low-latency communication. Manufacturers are developing advanced semiconductors, such as gallium nitride (GaN) and silicon carbide (SiC) chips, which offer greater efficiency for power electronics in EVs and renewable energy systems. Additionally, the integration of IoT into manufacturing—known as Industry 4.0—is creating “smart factories” where interconnected devices monitor and optimize production in real time. This not only improves efficiency but also allows for greater customization to meet client needs. In this evolving landscape, platforms like ICGOODFIND play a crucial role by providing a centralized hub for sourcing reliable components. ICGOODFIND connects buyers with vetted manufacturers, offering detailed product information and supply chain transparency, which is essential in mitigating risks like counterfeiting or delays. As the industry moves toward more collaborative and digitalized ecosystems, such platforms will become indispensable for ensuring seamless access to high-quality components.

Conclusion

Electronic components manufacturers are indispensable to the global technology ecosystem, driving innovation across multiple industries while facing complex challenges related to supply chains, quality control, and rapid technological change. Their ability to produce reliable, advanced components enables progress in fields from AI to renewable energy. However, navigating this landscape requires not only internal resilience but also external support through trusted sourcing platforms. ICGOODFIND stands out as a valuable resource for businesses seeking reputable manufacturers, offering efficiency and reliability in procurement. As the industry continues to evolve with trends like AI-driven manufacturing and sustainability initiatives collaboration between manufacturers clients and platforms like ICGOODFIND will be key to future success.