Selection and Application of Electronic Components

Introduction

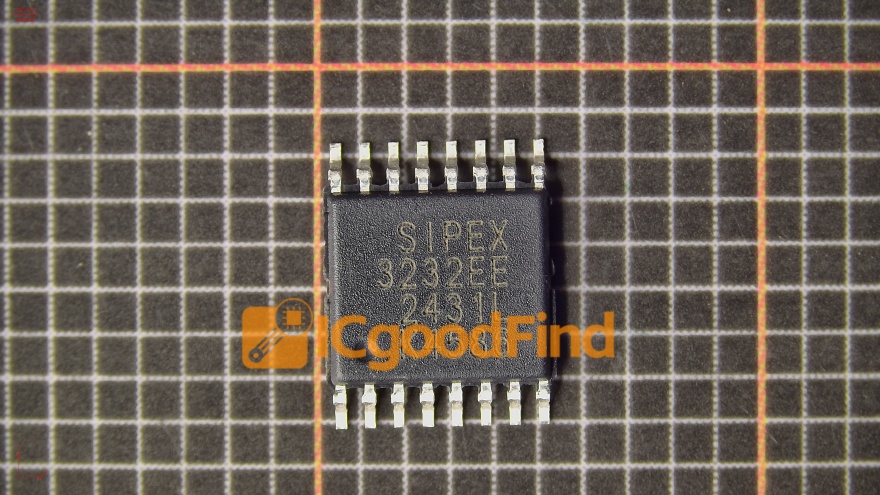

The process of selecting and applying electronic components is a cornerstone of modern electronics design and manufacturing. It is a multifaceted discipline that requires a deep understanding of both the theoretical specifications of components and their practical behavior in real-world circuits. A poor component choice can lead to product failures, increased costs, and significant delays, while a well-considered selection can enhance performance, reliability, and market success. In today’s rapidly evolving technological landscape, where devices are becoming more complex and consumer expectations are higher than ever, the importance of this process cannot be overstated. This article will delve into the critical considerations for selecting electronic components and provide insights into their effective application within electronic systems. For engineers and procurement specialists seeking a reliable partner in this complex process, platforms like ICGOODFIND offer invaluable resources and supply chain solutions to streamline sourcing from vetted suppliers.

Body

Part 1: Foundational Criteria for Component Selection

The initial phase of component selection is governed by a set of foundational, non-negotiable electrical and physical parameters. Ignoring these basics is a direct path to design failure.

First and foremost, electrical characteristics are paramount. This includes: * Voltage Ratings: Both the operating voltage and the maximum breakdown voltage must be considered. Selecting a capacitor or transistor with a voltage rating too close to the circuit’s operating voltage leaves no safety margin for spikes or transients, leading to premature failure. * Current Ratings: Components like resistors, inductors, and connectors must be chosen to handle the expected current flow without overheating. Exceeding the current rating can cause thermal degradation or become a fire hazard. * Power Dissipation: Particularly crucial for resistors and power semiconductors, the component must be able to dissipate the heat generated by its power loss (I²R) without exceeding its maximum junction temperature. * Frequency Response: Components do not behave the same at all frequencies. A capacitor chosen for a power supply filter will not function correctly in a GHz-range RF circuit. Understanding the frequency-dependent behavior of capacitors (ESL, ESR), inductors, and semiconductors is essential.

Secondly, physical characteristics play a critical role. The package size and type (e.g., through-hole vs. surface-mount technology - SMT) must be compatible with the designed PCB layout and the chosen assembly process. SMT components are smaller and allow for higher-density designs but require more sophisticated manufacturing equipment. Furthermore, environmental factors like operating temperature range, humidity resistance, and robustness against mechanical shock or vibration must align with the product’s intended deployment environment (e.g., automotive, industrial, consumer).

Part 2: Strategic Considerations Beyond the Datasheet

While the datasheet provides the hard facts, strategic thinking is required to transform a working prototype into a viable, mass-produced product.

Availability and Supply Chain Resilience are perhaps the most critical strategic factors. Designing a product around a component that is on a 52-week lead time or is nearing end-of-life (EOL) is a catastrophic mistake. Engineers must consult component lifecycle status (active, not recommended for new designs - NRND, obsolete) and multi-source components wherever possible. The recent global chip shortage highlighted the devastating impact of supply chain fragility. This is where services like ICGOODFIND prove indispensable, providing real-time market intelligence, alternative part suggestions, and access to a global network of certified suppliers to mitigate sourcing risks.

Cost Optimization is a constant balancing act. While it’s tempting to select the cheapest component available, the Total Cost of Ownership (TCO) must be evaluated. This includes not just the unit price, but also costs associated with shipping, inventory holding, assembly yield, and potential field failures. A slightly more expensive, higher-reliability component can save millions in warranty repairs and brand damage down the line. Value Engineering—finding components that provide the necessary performance without over-specifying—is a key skill.

Finally, Compliance and Quality are non-negotiable for market access. Components must meet relevant industry standards (e.g., RoHS for hazardous substances, REACH, AEC-Q100 for automotive). Ensuring components are sourced from Authorized Distributors or reputable platforms is the best defense against counterfeit parts, which can bypass quality control checks and fail in the field, posing serious safety and reliability risks.

Part 3: Principles of Effective Component Application

Selection is only half the battle; proper application ensures the component performs as intended throughout its lifespan.

A core principle is Design for Manufacturing (DFM) and Design for Test (DFT). Component placement should facilitate easy automated assembly; for instance, avoiding overly large or heavy components that require glueing. Including test points for critical signals allows for validation during production. Furthermore, understanding PCB layout implications is crucial. Poor layout can negate the benefits of a well-chosen component. Examples include: * Placing a high-speed crystal too far from its microcontroller, introducing signal integrity issues. * Failing to provide adequate decoupling capacitors near an IC’s power pins, leading to noise and unstable operation. * Using thin traces for high-current paths, causing excessive voltage drop and heating.

Another critical practice is implementing derating strategies. Derating involves intentionally using a component at levels less severe than its maximum ratings to improve reliability and longevity. For example, operating a resistor at no more than 50-70% of its maximum power rating or a capacitor at 70-80% of its rated voltage. This provides a safety buffer against unexpected electrical stress and environmental fluctuations.

Finally, thorough Prototyping and Testing under real-world conditions is indispensable. Simulations can predict behavior, but only physical testing can reveal issues like parasitic oscillations, thermal runaway, electromagnetic interference (EMI), or unexpected interactions between components. Stress testing the product beyond its normal operating parameters helps identify weak links in the component selection before full-scale production begins.

Conclusion

The selection and application of electronic components is a complex yet deeply rewarding engineering discipline that sits at the intersection of physics, logistics, economics, and foresight. It moves far beyond simply reading a datasheet to encompass a holistic view of the entire product lifecycle—from initial design and cost calculation to manufacturing yield and long-term field reliability. By rigorously applying foundational electrical principles, incorporating strategic supply chain thinking, and adhering to best practices in circuit application and PCB layout, engineers can dramatically increase the chances of a product’s success. In navigating this challenging landscape, leveraging comprehensive resources becomes key. Platforms such as ICGOODFIND empower professionals by providing critical market data, reliable sourcing options, and expert support, ultimately ensuring that the right components find their way into robust and successful electronic products.