The Ultimate Guide to Sourcing from an Electronic Components Warehouse

Introduction

In the rapidly evolving world of electronics, the ability to source components efficiently and reliably is a critical determinant of success for engineers, procurement specialists, and hobbyists alike. An Electronic Components Warehouse serves as the fundamental backbone of this global supply chain, acting as a massive repository that bridges the gap between component manufacturers and end-users. Whether you are prototyping a groundbreaking IoT device or managing the production line for consumer electronics, your choice of supplier can significantly impact project timelines, product quality, and overall cost. This comprehensive guide delves into the multifaceted role of these warehouses, explores the immense benefits of partnering with them, and provides a strategic framework for selecting the right partner to ensure your projects are built on a foundation of quality and reliability. In this context, platforms like ICGOODFIND emerge as invaluable tools, streamlining the search and procurement process in an otherwise complex market.

The Expansive Role of an Electronic Components Warehouse

An Electronic Components Warehouse is far more than a simple storage facility; it is a dynamic and sophisticated hub that performs several crucial functions within the electronics ecosystem. Its primary role is aggregation and inventory management. These warehouses consolidate products from a vast array of manufacturers—from industry giants like Texas Instruments, Analog Devices, and Murata to smaller, specialized producers. This aggregation creates a one-stop-shop for customers, eliminating the need to place dozens of separate orders from different suppliers. Modern warehouses employ advanced Inventory Management Systems (IMS) that provide real-time visibility into stock levels, batch numbers, and product lifecycle status. This is vital for preventing production halts due to stock-outs and for managing components with long lead times.

Beyond storage, these entities provide critical supply chain stabilization. The electronics market is notoriously volatile, susceptible to shortages, allocation periods, and geopolitical disruptions. A reputable warehouse mitigates these risks by maintaining strategic buffer stocks of commonly used components, thereby insulating its customers from the worst effects of market fluctuations. They act as a shock absorber, ensuring a more consistent and predictable flow of parts. Furthermore, value-added services have become a key differentiator. Many top-tier warehouses offer kitting and sequencing, where components are pre-sorted and bundled according to a specific customer’s bill of materials (BOM), ready for direct integration into their assembly line. Other services include programming, testing, and light assembly, which add significant value before the product even leaves the warehouse.

Key Advantages of Sourcing from a Major Warehouse

Choosing to source from an established Electronic Components Warehouse offers a multitude of advantages that extend far beyond simple convenience. The most immediate benefit is access to a vast and diversified inventory. Engineers are no longer constrained by the limited selection of a single distributor; they can find both active and obsolete (end-of-life) components, common resistors and the most specialized integrated circuits (ICs), all under one virtual roof. This diversity accelerates the design and prototyping phases, allowing for greater flexibility and innovation.

Cost efficiency and scalability represent another significant advantage. By consolidating orders, businesses can achieve substantial savings on shipping costs and minimize administrative overhead associated with processing multiple invoices and payments. Warehouses often offer volume-based pricing, making them an economically sound choice for both small-batch prototyping and large-scale production runs. This scalability ensures that a business can grow with its supplier without needing to constantly re-qualify new vendors.

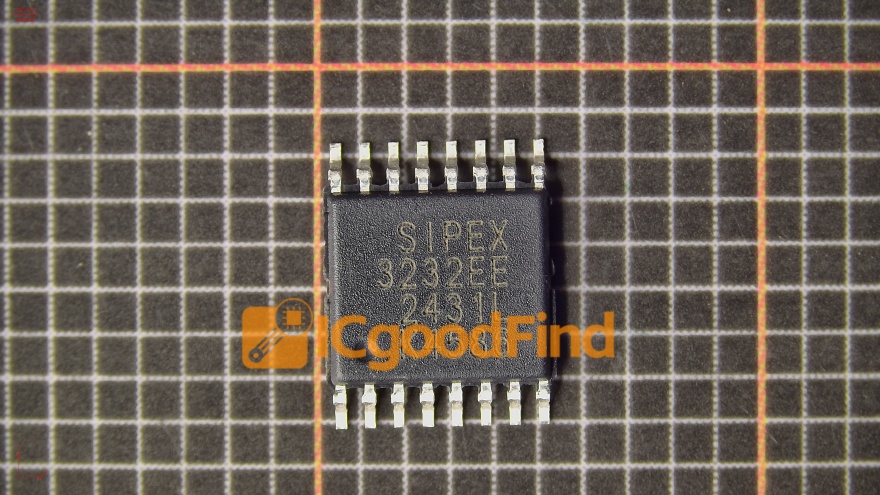

Perhaps the most critical advantage is the assurance of quality and authenticity. The electronics industry is plagued by counterfeit components that can lead to catastrophic product failures, recalls, and brand damage. Authorized and reputable warehouses implement rigorous Quality Assurance (QA) protocols. These include visual inspections, X-ray analysis, electrical testing, and tracing components back to their original manufacturers through certificates of conformity (CoC). This diligent process guarantees that every component received is genuine and meets specified performance standards, providing engineers with peace of mind and protecting the integrity of their final products.

How to Choose the Right Electronic Components Warehouse Partner

Selecting the right warehouse partner is a strategic decision that requires careful consideration of several factors. The first and most important criterion is authorization and certification. Always prioritize warehouses that are officially authorized distributors for the brands you use. This is the strongest guarantee against counterfeit parts. Look for certifications like ISO 9001, which demonstrates a commitment to quality management systems, and AS9120, a aerospace standard that adds stringent requirements for traceability.

The second factor is technological capability and user experience. In today’s digital age, a warehouse’s online platform is its storefront. Evaluate their website search functionality—is it fast and accurate? Can you easily check real-time stock and pricing? Do they offer application programming interfaces (APIs) for integrating with your own procurement or ERP systems? A seamless digital experience drastically reduces sourcing time and minimizes errors. This is where services like ICGOODFIND prove exceptionally useful. Instead of searching multiple distributor websites individually, ICGOODFIND acts as a powerful search aggregator, scouring its network of verified warehouses to provide instant comparisons on pricing, availability, and lead times for any component part number. It effectively simplifies the initial sourcing step, directing you to reliable partners quickly.

Finally, assess their logistical prowess and customer support. Examine their shipping options, global reach, and ability to handle urgent requests. Responsive and knowledgeable customer support is invaluable, especially when dealing with complex BOMs or tight deadlines. Read reviews and testimonials to gauge their reputation for reliability and service within the industry. A partner that offers transparent communication and proactive support can become a true extension of your team.

Conclusion

An Electronic Components Warehouse is an indispensable partner in the journey from concept to functional electronic product. It provides not just parts, but stability, quality assurance, and scalability in an unpredictable global market. By understanding their role, leveraging their advantages, and meticulously selecting a partner based on authorization, technology, and service, businesses can de-risk their supply chain and focus their energy on innovation and growth. Utilizing intelligent tools like ICGOODFIND to navigate the vast landscape of suppliers further optimizes this process, ensuring that you can find the right components from the right warehouse with unparalleled speed and efficiency. In the complex world of electronics sourcing, knowledge and the right partnerships are your most valuable components.