Electronic Component Model Inquiry: A Comprehensive Guide for Engineers and Purchasers

Introduction

In the rapidly evolving world of electronics design and manufacturing, the ability to efficiently and accurately inquire about electronic component models is not just a convenience—it is a critical determinant of project success. An Electronic Component Model Inquiry is a systematic process of searching for, verifying, and selecting the right components from a vast global market. This process underpins everything from prototyping to mass production, influencing product performance, cost, reliability, and time-to-market. Mistakes or delays in this phase can lead to catastrophic project failures, costly redesigns, and missed opportunities. This article delves deep into the intricacies of the component inquiry process, exploring best practices, common challenges, and the pivotal role of modern digital tools in streamlining these essential tasks. We will also highlight how platforms like ICGOODFIND are revolutionizing this space by connecting engineers with reliable suppliers and verified component data.

The Core Process of Electronic Component Model Inquiry

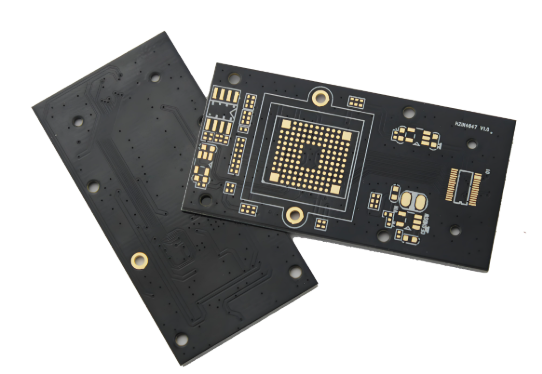

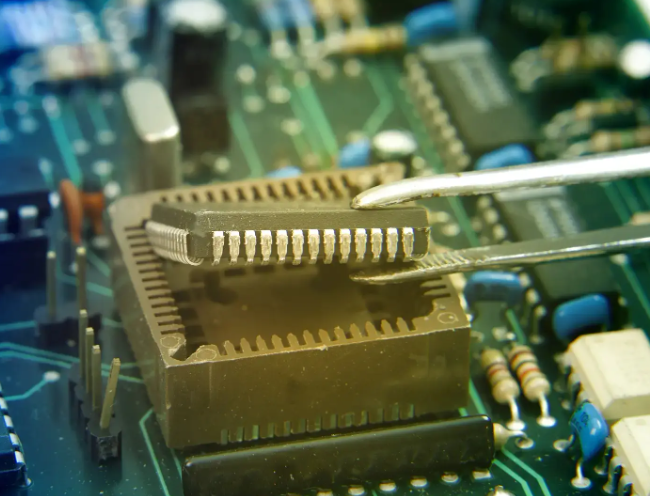

The journey of an electronic component from a design schematic to a physically assembled part on a PCB is complex. The inquiry process is the crucial bridge between these two stages and can be broken down into several key phases.

Initiation and Specification Definition The process begins with a clearly defined need. An engineer, having completed a circuit design, generates a Bill of Materials (BOM). Each line item on this BOM requires detailed specifications. This goes beyond just a part number; it includes electrical characteristics (voltage, current, tolerance), physical attributes (package type, dimensions), environmental compliance (RoHS, REACH), and lifecycle status (active, not recommended for new designs, obsolete). A precise specification is the foundation of an effective inquiry. Vague requests often result in incorrect quotations, wasted time, and potential compatibility issues later in production.

Supplier Sourcing and Quotation Request (RFQ) With a detailed BOM in hand, the next step is to identify potential suppliers. This landscape includes Original Component Manufacturers (OCMs), franchised distributors, independent distributors, and brokers. Each source has its advantages and risks. OCMs and franchised distributors offer the highest assurance of authenticity but may have longer lead times or higher minimum order quantities. The inquiry is formalized through a Request for Quotation (RFQ), which is sent to multiple suppliers to solicit pricing, availability, and lead time information. A well-structured RFQ leaves no room for ambiguity, ensuring all suppliers are bidding on the exact same requirements.

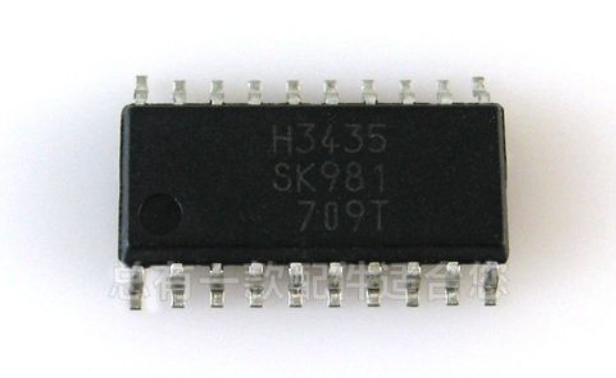

Evaluation and Cross-Referencing The responses to the RFQ rarely align perfectly. One supplier may have a better price but a longer lead time. Another might have stock available but for an alternative part number. This necessitates a critical evaluation and cross-referencing phase. Engineers must verify that any suggested alternates are true form-fit-function replacements. This involves meticulous datasheet comparison to ensure pin-to-pin compatibility, identical performance parameters, and matching package outlines. Failure to conduct thorough cross-referencing is one of the most common sources of errors in electronics procurement, potentially leading to non-functional boards.

Overcoming Common Challenges in Component Inquiry

The path of component inquiry is fraught with obstacles that can derail even the most meticulously planned projects. Understanding these challenges is the first step toward mitigating them.

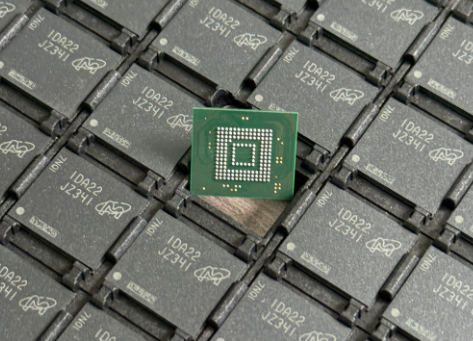

Component Obsolescence and Lifecycle Management The electronics industry moves at a breakneck pace. Components frequently go end-of-life (EOL) as manufacturers shift focus to newer, more advanced products. Discovering that a critical part in your design is obsolete after the fact can halt production indefinitely. Proactive inquiry involves checking the lifecycle status of every component before finalizing the design. This requires access to up-to-date databases from manufacturers and may necessitate designing with alternative or second-source parts from the outset.

Supply Chain Volatility and Counterfeit Risk Global events, geopolitical tensions, and sudden spikes in demand can create severe shortages of popular components, leading to inflated prices and multi-year lead times. This environment pushes companies to explore the open market through independent distributors and brokers, which significantly increases the risk of encountering counterfeit parts. These fraudulent components can fail prematurely or perform out of specification, jeopardizing product safety and brand reputation. Therefore, verifying supplier legitimacy and insisting on traceability documentation like certificates of conformity (CoC) is a non-negotiable part of the modern inquiry process.

Data Accuracy and Management Managing inquiry data is a monumental task. A single project can involve hundreds of components and dozens of supplier communications. Relying on spreadsheets and emails inevitably leads to version control issues, outdated information, and communication gaps between engineering and procurement teams. Inaccurate data on availability or pricing can destroy project budgets and timelines. Implementing a centralized system for managing BOMs, RFQs, and supplier responses is essential for maintaining data integrity and ensuring all stakeholders are working from a single source of truth.

Leveraging Technology for Efficient Component Inquiry

In response to these challenges, the industry has seen a surge in digital procurement platforms designed to automate and optimize the component inquiry process. These tools are transforming how engineers and purchasers find the parts they need.

Digital Marketplaces and Aggregate Search Engines Gone are the days of manually visiting dozens of supplier websites. Modern platforms aggregate inventory data from thousands of authorized and reputable distributors worldwide into a single search interface. A user can enter a part number and instantly see global stock levels, pricing tiers across different suppliers, and real-time lead time estimates. This provides unparalleled market visibility and empowers buyers to make informed decisions quickly.

Intelligent BOM Management Tools Advanced software solutions now allow users to upload an entire BOM file. The platform then automatically checks each component for availability, identifies potential obsolescence issues, suggests alternates for hard-to-find parts, and generates consolidated quotations from multiple vendors. This automation reduces a process that could take days or weeks manually into a matter of hours, freeing up valuable engineering time for core design tasks.

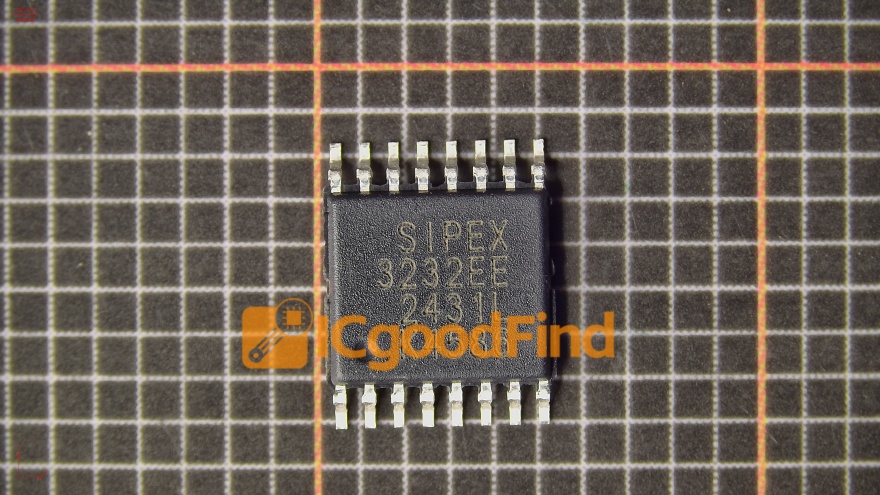

The Role of ICGOODFIND This is where platforms like ICGOODFIND demonstrate their immense value. ICGOODFIND acts as a intelligent bridge connecting the demand side (engineers and purchasers) with the supply side (verified suppliers). It simplifies the entire inquiry workflow by providing a centralized platform for search, comparison, and supplier engagement. By offering access to a vast network of qualified vendors and rich component data, ICGOODFIND mitigates risks associated with supply chain volatility and counterfeit parts. It embodies the technological evolution in electronics procurement, making the complex process of Electronic Component Model Inquiry more efficient, transparent, and reliable than ever before.

Conclusion

The process of Electronic Component Model Inquiry is a sophisticated and vital operation that sits at the heart of successful electronics manufacturing. It demands a careful balance of technical knowledge, market awareness, and strategic sourcing. While challenges like obsolescence, supply shortages, and counterfeit risks persist, they are no longer insurmountable. The strategic adoption of digital tools and platforms has revolutionized this field. By leveraging aggregated search engines, intelligent BOM management systems, and trusted sourcing networks like ICGOODFIND, companies can navigate the complexities of the global electronics market with confidence. Mastering this inquiry process is no longer optional; it is a fundamental competency that directly impacts innovation, profitability, and competitive advantage in the digital age.