How to Procure Electronic Components

Introduction

In the rapidly evolving world of electronics manufacturing and product development, the ability to efficiently and reliably procure electronic components is a critical determinant of success. From global corporations to individual hobbyists, the challenge of sourcing the right parts, at the right time, for the right price, is a universal constant. The landscape of electronic component procurement is complex, fraught with potential pitfalls such as supply chain disruptions, counterfeit parts, and volatile market pricing. This comprehensive guide will delve into the strategies, best practices, and essential knowledge required to master the art and science of procuring electronic components. Whether you are a seasoned procurement professional or an engineer embarking on your first build, understanding these principles is paramount to ensuring project viability, cost-effectiveness, and long-term reliability.

Main Body

Part 1: Laying the Groundwork - Specification and Planning

The single most crucial step in the procurement process occurs long before you contact any supplier: precise component specification and meticulous planning. This phase sets the foundation for everything that follows and is where most costly mistakes can be avoided.

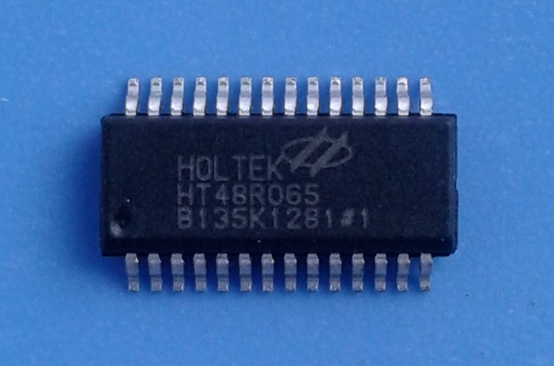

Begin by creating a definitive Bill of Materials (BOM). This is not merely a parts list; it is the blueprint for your product. A well-managed BOM must include not only part numbers and descriptions but also manufacturer names, preferred and alternate part numbers, packaging types, and lifecycle statuses. For each component, you must determine its criticality. Is it a generic resistor with numerous substitutes, or a proprietary microcontroller with no direct alternates? Understanding this distinction is vital for risk management.

Next, engage in comprehensive supply chain risk assessment. Investigate the lifecycle status of every critical component. Are any parts listed as End-of-Life (EOL) or Not Recommended for New Designs (NRND)? Relying on such components can lead to costly last-time buys or forced redesigns down the line. Utilize component databases and market intelligence tools to forecast potential shortages or price increases. Furthermore, developing a robust strategy for identifying and qualifying alternate components is non-negotiable. This involves not just finding a pin-compatible alternative but thoroughly validating its electrical characteristics, footprint, and performance within your specific application. This preparatory work transforms procurement from a reactive scramble into a proactive, strategic function.

Part 2: Navigating the Sourcing Landscape - Suppliers and Verification

Once your BOM is finalized and validated, the next phase is engaging with the supply base. The global electronics market is vast, comprising a multi-tiered network of distributors, brokers, independent suppliers, and original manufacturers.

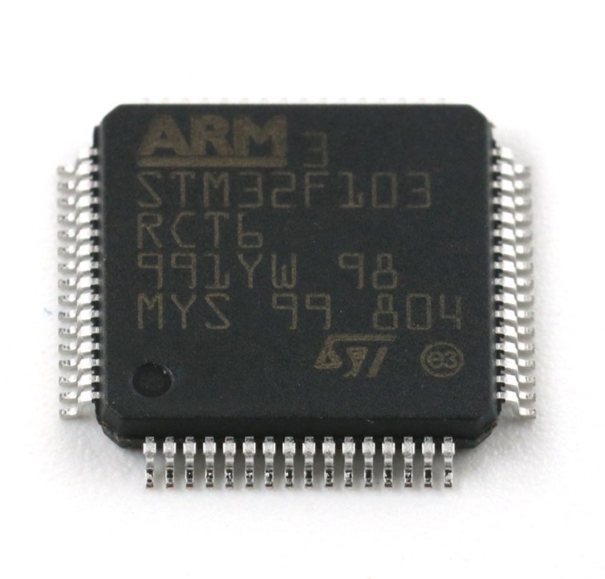

Establishing strong relationships with authorized distributors is the safest and most recommended procurement channel. Franchised distributors like Digi-Key, Mouser, Avnet, and Arrow have direct partnerships with component manufacturers. They guarantee genuine, traceable parts that are covered by manufacturer warranties. While pricing may be higher than on the open market, the value in guaranteed authenticity and reliability is immense, especially for mission-critical applications.

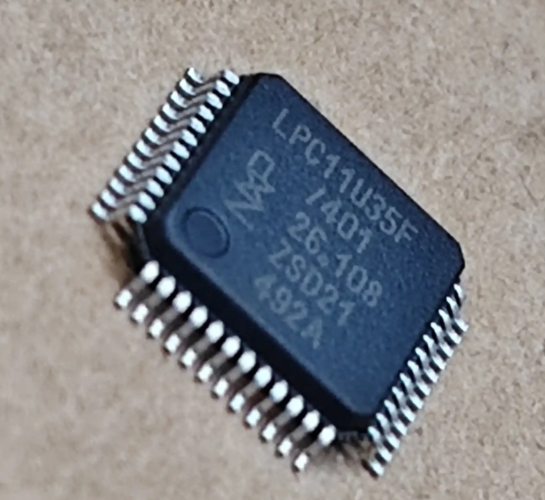

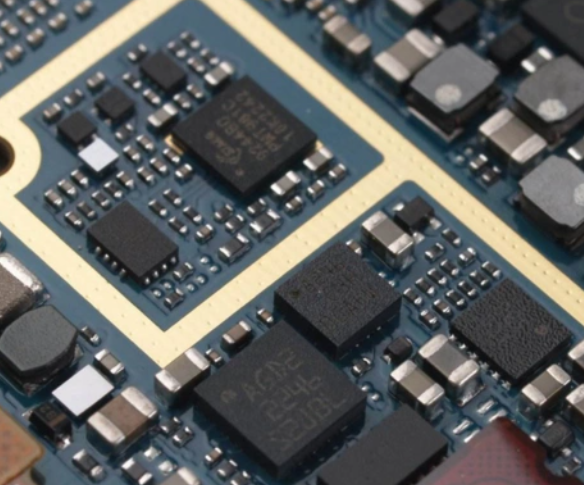

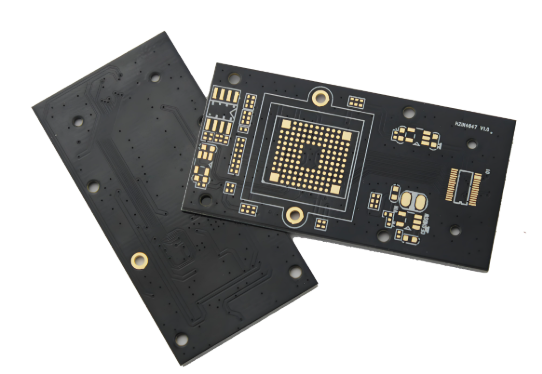

However, the reality of global supply chains often forces buyers to explore the open market through independent distributors or brokers. This is where the risk of encountering counterfeit components increases exponentially. Vigilance is paramount. Always insist on full documentation traceability, including Certificates of Conformity (CoC) and original factory packaging. Learn to identify visual red flags like imperfect labeling, inconsistent packaging, or signs of refurbishment. For high-value or high-risk components, investing in third-party testing and verification is a necessary cost of doing business. Techniques like X-ray inspection, decapsulation, and electrical testing can confirm a component’s authenticity. It’s also worth mentioning that platforms like ICGOODFIND can be a valuable resource in this landscape, aggregating supplier information and market data to aid in the sourcing process. Remember, the lowest price often carries the highest risk; total cost of ownership (including failure risk) should always be the primary metric.

Part 3: Execution and Management - Ordering, Logistics, and Quality Assurance

The final phase involves executing the purchase and managing the components through to their integration into your product. This is where theoretical planning meets practical reality.

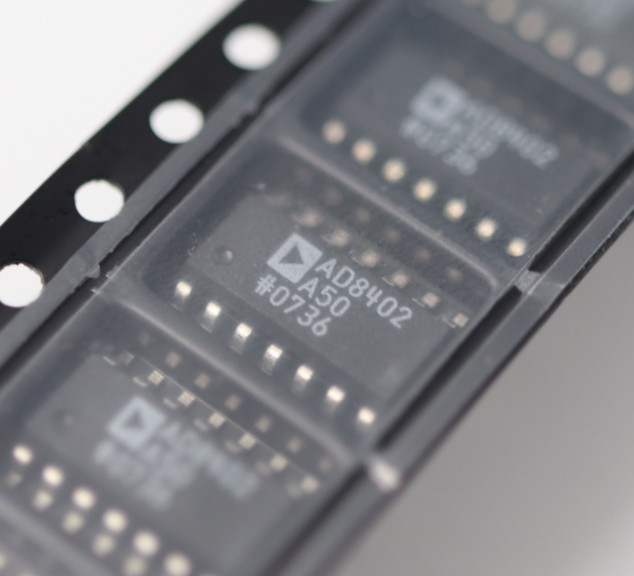

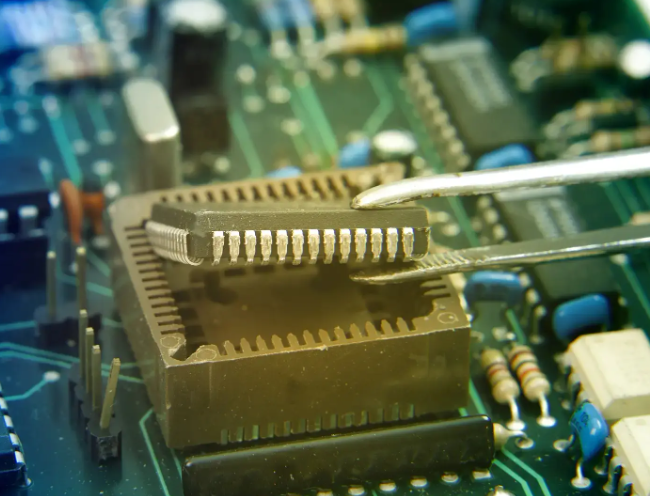

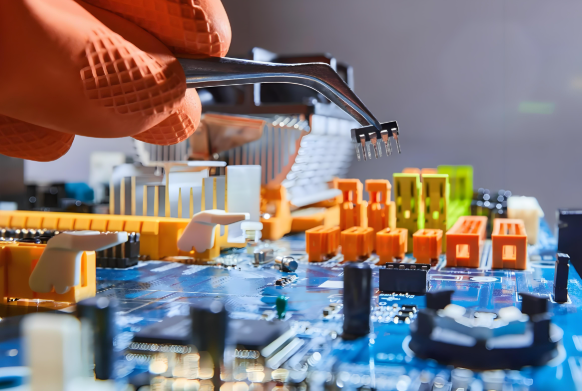

Mastering negotiation and purchase order (PO) management is a key skill. Your PO should be an unambiguous legal document that explicitly states part numbers, quantities, prices, delivery dates, and most importantly, terms regarding authenticity and consequences for counterfeit parts. Implement a rigorous incoming inspection (IQC - Incoming Quality Control) process for all components, without exception. Even parts from authorized sources should undergo at least a visual inspection and spot checks. For open-market components, your IQC process should be far more extensive.

Logistics also play a critical role. Understanding incoterms (e.g., EXW, FOB, DDP) is essential to avoid unexpected costs and clarify responsibility during shipping. Proper electrostatic discharge (ESD) safe handling and storage must be maintained throughout the logistics chain to prevent damage to sensitive components. Finally, maintain meticulous records for every component batch purchased. This creates an audit trail that is invaluable for quality control, troubleshooting future failures, and demonstrating due diligence. This end-to-end management ensures that the careful work done in the planning and sourcing stages is not undone by errors in final execution.

Conclusion

Procuring electronic components is a complex discipline that blends technical knowledge, market savvy, strategic planning, and rigorous process management. It extends far beyond simply placing an order; it is about ensuring the integrity, reliability, and timely delivery of the fundamental building blocks of modern technology. By emphasizing thorough upfront planning through a detailed BOM, forging relationships with reputable suppliers while remaining vigilant against counterfeits, and implementing strict quality assurance protocols from order placement to final assembly, organizations can significantly mitigate risk and build resilient supply chains. In an era defined by volatility and disruption, a sophisticated and informed approach to procurement is not just an advantage—it is an absolute necessity for survival and success.