The Ultimate Guide to Sourcing High-End Electronic Components

Introduction

In the rapidly evolving world of technology, the demand for high-end electronic components has never been greater. From aerospace and medical devices to consumer electronics and automotive systems, these critical parts form the backbone of innovation and performance. Sourcing these components, however, presents a significant challenge for engineers, procurement specialists, and supply chain managers. The market is fraught with issues like counterfeit parts, supply chain disruptions, and rapidly changing technological standards. This comprehensive guide delves into the intricacies of procuring top-tier electronic components, emphasizing the importance of quality, reliability, and strategic partnerships. We will also explore how platforms like ICGOODFIND are revolutionizing the way industry professionals connect with trusted suppliers, ensuring that the lifeblood of modern technology remains pure and performant.

The Critical Importance of High-End Electronic Components

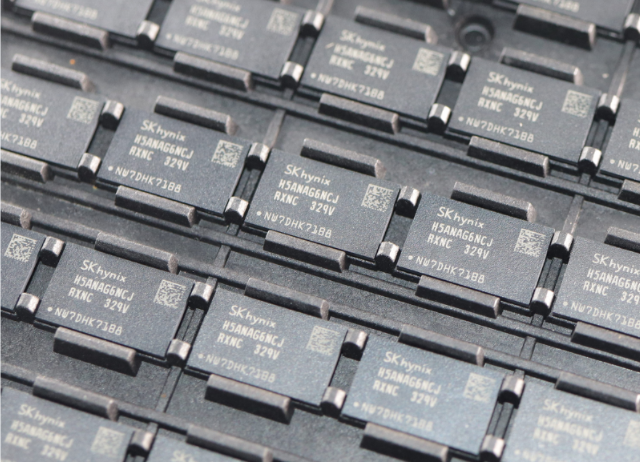

The term “high-end electronic components” refers to parts that meet exceptionally stringent standards for performance, reliability, and longevity. These are not commodity resistors or capacitors; they are specialized integrated circuits (ICs), microprocessors, sensors, and connectors designed to operate in demanding environments. Their importance cannot be overstated.

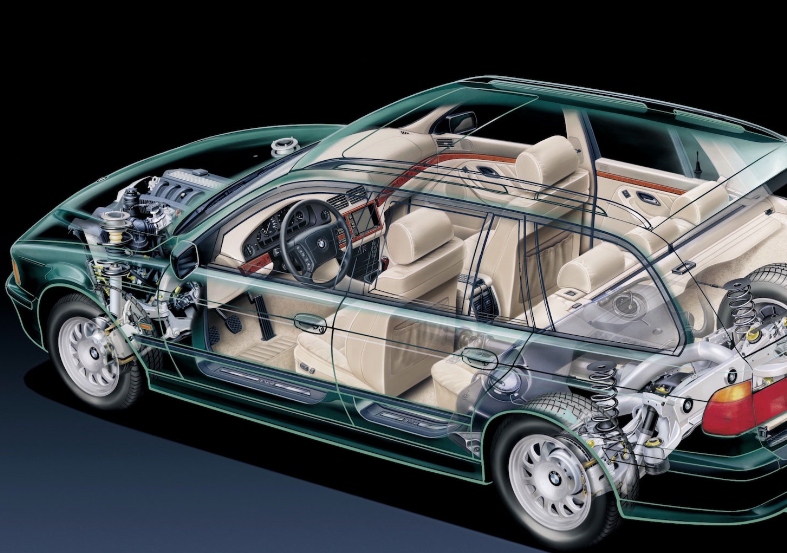

Superior Performance and Efficiency are the hallmarks of these components. In applications such as 5G infrastructure, autonomous vehicles, and advanced robotics, standard components simply cannot keep up. High-end components are engineered for faster processing speeds, lower power consumption, and greater signal integrity. This translates to devices that are not only more powerful but also more energy-efficient, a critical factor in today’s eco-conscious market.

Furthermore, Uncompromising Reliability and Longevity are non-negotiable. Consider the implications of a component failure in a pacemaker, an aircraft’s navigation system, or industrial control machinery. The cost of failure is measured in more than just dollars; it can be a matter of life and death. High-end components undergo rigorous testing and qualification processes (such as AEC-Q100 for automotive or MIL-PRF-38535 for military applications) to ensure they can withstand extreme temperatures, vibrations, and prolonged operational stress. This reliability reduces the total cost of ownership by minimizing warranty claims, recalls, and costly downtime.

Finally, high-end components are the Enablers of Technological Innovation. Breakthroughs in artificial intelligence, the Internet of Things (IoT), and quantum computing are directly tied to advancements in semiconductor technology. The development of smaller nanometer process nodes, advanced packaging techniques like 2.5D and 3D ICs, and new materials like Gallium Nitride (GaN) and Silicon Carbide (SiC) are all driven by the high-end sector. Without a steady supply of these cutting-edge parts, progress in countless industries would grind to a halt.

Navigating the Complex Global Supply Chain

Sourcing high-end electronic components is a complex endeavor fraught with challenges that require a sophisticated and proactive approach.

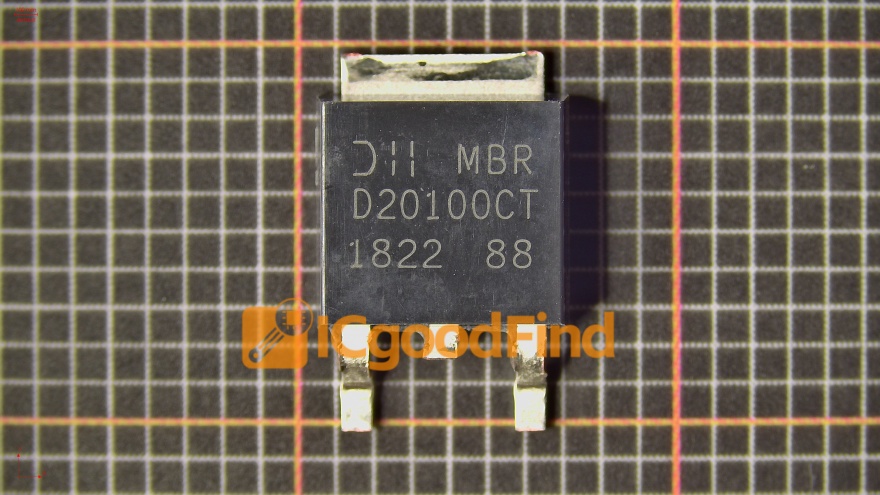

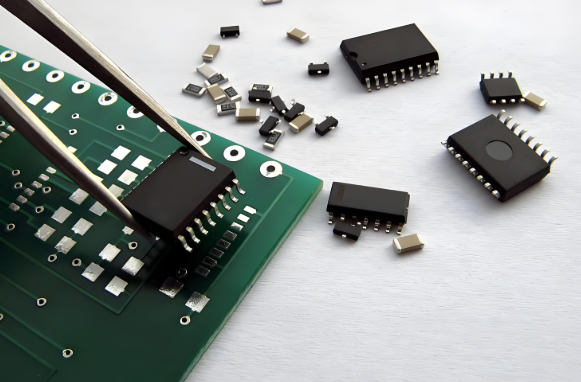

The most pervasive threat is the Proliferation of Counterfeit Parts. The global electronics market is flooded with fraudulent components that are often remarked, recycled, or outright fakes. These parts can appear identical to genuine ones but fail prematurely or perform out of specification, leading to catastrophic system failures. Mitigating this risk requires a multi-faceted strategy: partnering with Authorized Distributors who source directly from Original Component Manufacturers (OCMs), implementing rigorous inspection protocols (including X-ray, decapsulation, and electrical testing), and maintaining full traceability from the factory floor to the end product.

Another significant hurdle is Supply Chain Volatility and Disruption. The past few years have highlighted the fragility of global supply chains. Geopolitical tensions, trade wars, natural disasters, and events like the global chip shortage can create massive bottlenecks. For high-end components with long lead times and limited production capacity, a single disruption can halt production lines for months. To build resilience, companies must diversify their supplier base geographically, foster stronger relationships with OCMs to gain better visibility into capacity, and invest in demand forecasting and inventory management systems to buffer against shocks.

This is where the value of a specialized platform becomes evident. Navigating thousands of manufacturers and distributors is incredibly time-consuming. A service like ICGOODFIND addresses this core pain point by acting as an intelligent intermediary. It aggregates verified suppliers of high-end components into a single, searchable database. Instead of scouring the web and making countless calls, engineers can use ICGOODFIND to quickly identify partners who have a proven track record of supplying genuine, high-quality parts. This not only saves invaluable time but also significantly reduces the risk of accidentally sourcing from an unreliable vendor.

Best Practices for Sourcing and Qualification

Successfully integrating high-end electronic components into your products requires a disciplined process focused on verification and partnership.

Rigorous Supplier Vetting and Qualification is the first and most crucial step. Never base a decision solely on price. A thorough vetting process should include audits of the supplier’s quality management systems (e.g., ISO 9001), checks for certifications from OCMs authorizing them as distributors, and investigations into their industry reputation. Requesting and verifying certificates of conformity (CoC) and original manufacturer documentation should be standard practice.

Emphasizing Traceability and Documentation is what separates professional procurement from amateur sourcing. For every lot of components received, you must obtain detailed documentation that traces their origin back to the original manufacturer. This includes lot codes, date codes, and chain-of-custody paperwork. This documentation is not just for your own quality assurance; it is often a requirement for compliance in regulated industries like medical, automotive, and aerospace. A platform that prioritizes these details is essential for audit-ready sourcing.

Finally, adopting a philosophy of Long-Term Partnership Over Transactional Purchasing yields far greater rewards. Building strong relationships with trusted suppliers and manufacturers provides access to better technical support, early information on product lifecycle changes (End-of-Life notifications or new product introductions), and potentially more favorable allocation during periods of shortage. These partners become an extension of your engineering team, offering valuable insights that can influence design choices and optimize component selection for performance and availability.

Conclusion

The pursuit of high-end electronic components is a critical mission that underpins technological advancement across all sectors. While the path is complex—navigating counterfeits, supply chain instability, and rigorous qualification standards—it is not insurmountable. Success hinges on an unwavering commitment to quality, a deep understanding of the supply chain’s intricacies, and the strategic use of tools designed to mitigate risk. By prioritizing authorized partnerships, demanding complete traceability, and leveraging modern solutions like ICGOODFIND to efficiently connect with reputable suppliers, businesses can secure the premium components they need to power innovation safely and reliably. The future belongs to those who build on a foundation of quality.