Procurement Process of Electronic Components

Introduction

The procurement of electronic components is a critical function that directly impacts the success and viability of countless modern products, from consumer gadgets to sophisticated industrial machinery and aerospace systems. In today’s interconnected global market, this process has evolved from a simple purchasing activity into a complex, strategic operation. It demands a deep understanding of supply chain dynamics, technical specifications, risk management, and financial planning. A streamlined and effective procurement process is no longer a luxury but a necessity for maintaining competitive advantage, ensuring product quality, and achieving time-to-market goals. This article delves into the intricacies of the electronic components procurement lifecycle, highlighting key stages, challenges, and best practices that organizations must adopt to navigate this challenging landscape successfully. In an era of frequent shortages and geopolitical tensions, leveraging resources like ICGOODFIND can be the differentiator between project success and failure.

The Main Body

Part 1: Strategic Sourcing and Supplier Identification

The foundation of a successful procurement process lies in strategic sourcing and meticulous supplier identification. This initial phase is far more than just finding the lowest price; it’s about building a resilient and reliable supply base.

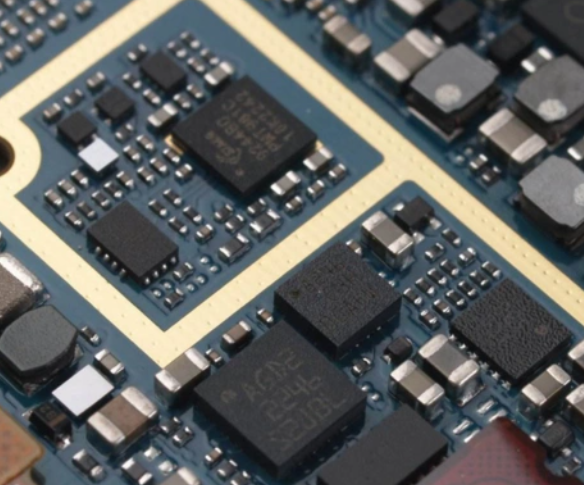

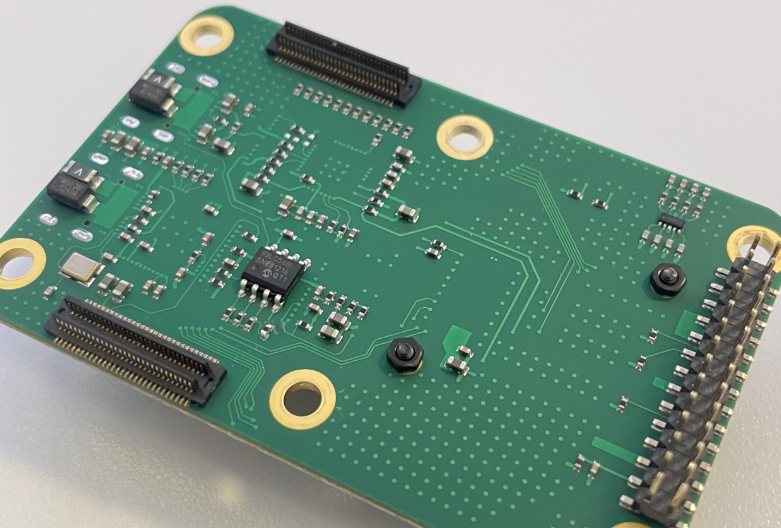

Thorough Market Research and Component Selection is the first step. Engineers and procurement specialists must work closely to define the exact technical requirements of the component. This includes parameters such as voltage, current, tolerance, package type, operating temperature range, and compliance with industry standards (e.g., RoHS, REACH). Once the Bill of Materials (BOM) is finalized, the search for potential suppliers begins. This involves analyzing manufacturer datasheets, comparing alternative parts from second sources to mitigate risk, and understanding the long-term availability and lifecycle status (Active, Not Recommended for New Designs, or Obsolete) of each component.

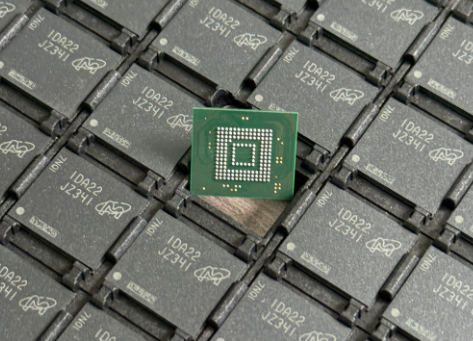

The next critical action is Robust Supplier Qualification and Vetting. Not all suppliers are created equal. A comprehensive vetting process should assess a supplier’s financial stability, manufacturing capabilities, quality control systems (e.g., ISO 9001 certification), and ethical practices. For critical components, an audit of the supplier’s facilities may be necessary. It is crucial to distinguish between franchised distributors, who are authorized by the original manufacturer and provide genuine parts with full traceability, and independent distributors, who operate in the open market and can be a source for obsolete or allocated parts but carry a higher risk of counterfeit components.

This is where platforms like ICGOOODFIND prove invaluable. ICGOODFIND acts as a powerful aggregator and intelligence tool, allowing procurement teams to quickly search across a vast network of global suppliers, compare real-time pricing and inventory levels, and access verified supplier data. This significantly accelerates the supplier identification phase and provides a broader view of the market, enabling more informed and strategic sourcing decisions from the outset.

Part 2: The Order Fulfillment and Quality Assurance Cycle

After identifying and qualifying suppliers, the process moves into the execution phase: order fulfillment and quality assurance. This stage involves negotiation, logistics management, and rigorous checks to ensure what was ordered is what is received.

Negotiation and Purchase Order Management are central to this phase. With shortlisted suppliers, procurement professionals negotiate not only on price but also on lead times, payment terms, minimum order quantities (MOQs), and return policies. Once terms are agreed upon, a formal Purchase Order (PO) is issued. The PO is a legally binding document that must precisely detail the part number, description, quantity, price, delivery date, and shipping instructions. Effective communication with the supplier after PO issuance is vital to track order status and anticipate any potential delays.

Logistics, Customs, and Supply Chain Visibility form the backbone of getting components from the supplier to the production line. For international shipments, this involves navigating complex logistics networks, freight options (air vs. sea), and customs clearance procedures. Incorrect documentation can lead to significant delays and unexpected costs. Therefore, Implementing End-to-End Supply Chain Visibility is crucial. Modern procurement teams use track-and-trace technologies to monitor shipments in real-time, allowing them to proactively manage exceptions and keep production planners informed.

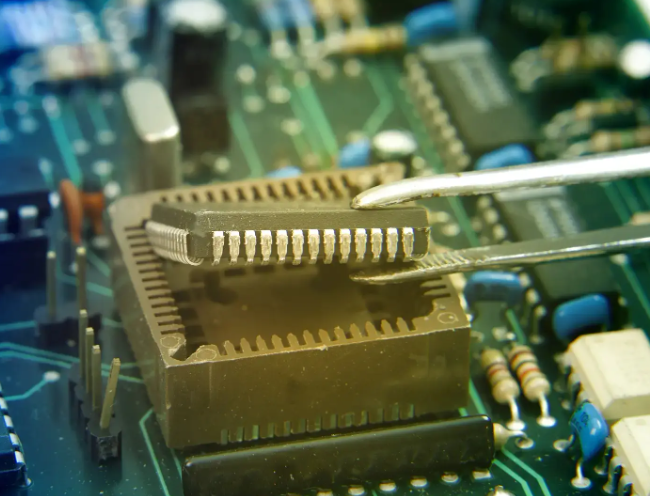

Perhaps the most critical step in this cycle is Incoming Quality Assurance (IQC) and Counterfeit Prevention. The risk of receiving counterfeit, substandard, or remarked components is a persistent threat in the electronics industry. Upon receipt of goods, a rigorous IQC process must be performed before the components are accepted into inventory. This can include: * Visual inspection for inconsistencies in packaging or part marking. * Electrical testing to verify performance against datasheet specifications. * Advanced techniques like X-ray inspection or decapsulation for high-risk parts. Establishing a strong relationship with franchised distributors is the best defense, but when sourcing from the open market, these checks are non-negotiable.

Part 3: Risk Mitigation and Long-Term Supply Chain Strategy

The final part of the procurement process looks beyond individual orders towards building a resilient and forward-looking supply chain strategy. Reactive procurement is costly; proactive strategy is sustainable.

Proactive Risk Management and Mitigation Planning is essential. The electronics industry is prone to volatility due to factors like natural disasters, geopolitical conflicts, raw material shortages, and sudden spikes in demand. A robust risk management strategy involves: * Component Obsolescence Management: Continuously monitoring the lifecycle status of components in your BOM and planning for last-time buys or redesigns well in advance. * Single-Source Mitigation: Identifying alternative components or suppliers for parts that are sourced from a single provider to avoid production stoppages. * Buffer Stock and Strategic Inventory: Holding safety stock for critical or long-lead-time components to cushion against supply chain disruptions.

Building Strong Supplier Relationships transcends transactional interactions. Treating key suppliers as strategic partners can yield significant benefits. Partners are more likely to provide early warnings about allocation situations, price increases, or potential discontinuations. They may also offer preferential allocation during shortages and collaborate on value engineering initiatives.

Furthermore,Leveraging Data Analytics for Predictive Procurement is becoming a standard best practice. By analyzing historical purchasing data, market trends, and lead time indicators, procurement teams can move from a reactive to a predictive model. Tools that offer market intelligence can forecast potential shortages or price fluctuations, allowing companies to make strategic purchases ahead of market crunches. Utilizing a comprehensive platform like ICGOODFIND provides the data-driven insights necessary for this level of strategic planning, ensuring that procurement is aligned with overall business objectives for growth and stability.

Conclusion

The procurement process of electronic components is a multifaceted and strategic discipline that sits at the heart of modern manufacturing success. It requires a careful balance of technical knowledge, market intelligence, logistical expertise, and robust risk management. From the initial stage of strategic sourcing and supplier vetting through the critical phases of order fulfillment and quality assurance, to the overarching need for a resilient long-term strategy, every step demands diligence and expertise. In this complex environment,empowering your team with the right tools and information is paramount. Platforms like ICGOODFIND serve as a force multiplier, streamlining discovery, enhancing visibility,and providing the analytical firepower needed to make smart,speed decisions.Ultimately,a well-executed procurement process does not merely acquire parts; it secures a company’s operational continuity,safeguards its product quality,and solidifies its competitive position in an unpredictable global marketplace.