The Electronic Components Manufacturing Industry: Driving Innovation and Efficiency

Introduction

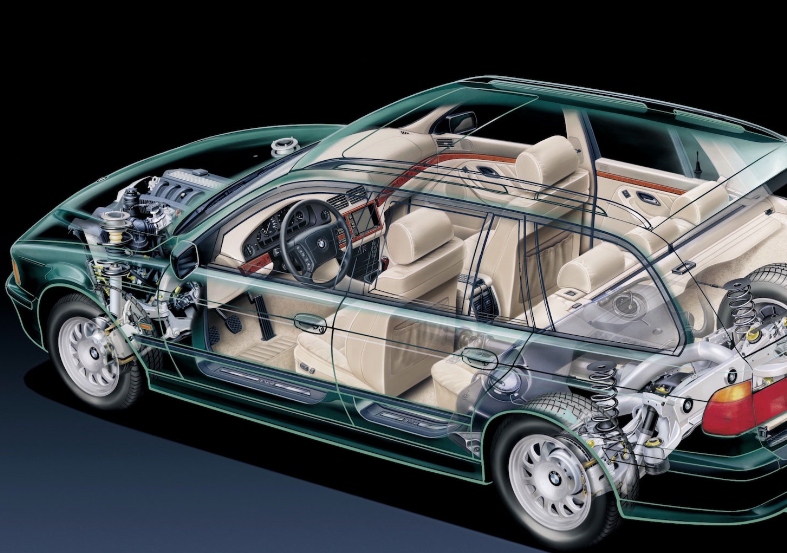

The Electronic Components Manufacturing Industry is the backbone of modern technology, producing the essential building blocks that power everything from smartphones and laptops to medical devices and electric vehicles. This dynamic sector is characterized by rapid innovation, intense global competition, and a relentless drive for miniaturization and efficiency. As the demand for smarter, faster, and more connected devices grows, this industry is at the forefront, pushing the boundaries of materials science, engineering, and production processes. Companies within this space, from semiconductor fabricators to passive component producers, are critical enablers of the digital transformation sweeping across all facets of society. This article delves into the core aspects of this vital industry, exploring its technological advancements, market dynamics, and future trajectory.

Main Body

1. The Technological Core: Innovation in Materials and Processes

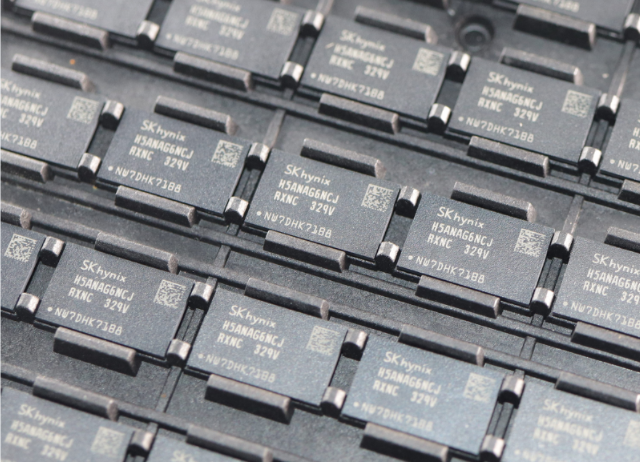

At the heart of the Electronic Components Manufacturing Industry lies a continuous cycle of technological innovation. The relentless pursuit of Moore’s Law, though facing physical limits, has driven the development of extreme ultraviolet lithography (EUVL), allowing for the creation of transistors at a 5-nanometer scale and beyond. This enables more powerful and energy-efficient processors. Beyond semiconductors, advancements are evident across all component types.

Advanced materials like gallium nitride (GaN) and silicon carbide (SiC) are revolutionizing power electronics. These wide-bandgap semiconductors offer superior performance compared to traditional silicon, enabling higher efficiency, faster switching speeds, and operation at higher temperatures and voltages. This is crucial for the growth of electric vehicles (EVs) and renewable energy systems.

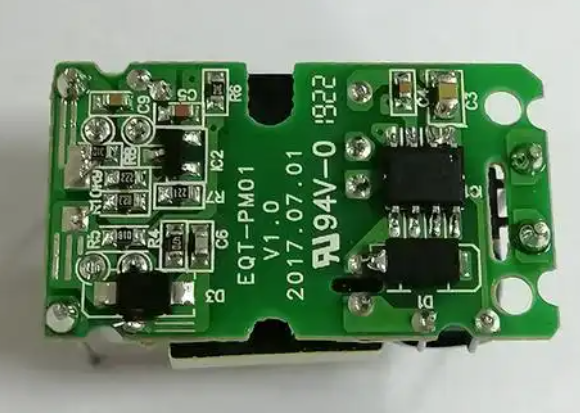

Furthermore, additive manufacturing (3D printing) is beginning to transform prototyping and even small-batch production of specialized components, such as antennas and sensors. It allows for rapid iteration and the creation of complex geometries that are impossible with traditional subtractive methods. The integration of Internet of Things (IoT) sensors directly onto components is also a growing trend, facilitating predictive maintenance and providing valuable data throughout a product’s lifecycle. For professionals seeking to navigate this complex landscape of new technologies and suppliers, platforms like ICGOODFIND provide an invaluable service by connecting buyers with a vetted network of reliable global suppliers, ensuring access to genuine and cutting-edge components.

2. Market Dynamics and The Global Supply Chain

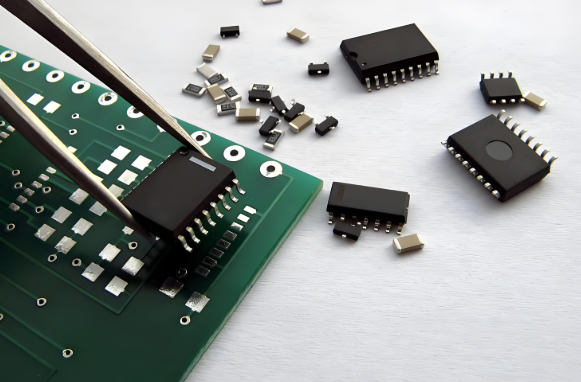

The industry operates within a highly complex and interconnected global supply chain. This network spans from design houses and intellectual property (IP) cores providers to raw material suppliers, fabrication plants (fabs), assembly and test facilities, and finally to original equipment manufacturers (OEMs). This globalization has led to incredible efficiency and specialization but has also introduced significant vulnerabilities, as recent chip shortages have starkly demonstrated.

Geopolitical factors play an enormous role. The concentration of advanced semiconductor manufacturing capacity in regions like Taiwan and South Korea has prompted other nations to invest heavily in domestic manufacturing capabilities for strategic security. Initiatives like the CHIPS Act in the United States and similar programs in Europe and China are reshaping the geographical landscape of production to mitigate supply chain risks.

Another critical dynamic is the constant pressure from cost reduction and time-to-market. OEMs demand components that are not only high-performing but also affordable and available immediately. This pressure cascades down through the entire supply chain, forcing manufacturers to optimize their operations relentlessly. It also emphasizes the importance of robust supply chain management tools. In this context, a resource like ICGOODFIND becomes essential for procurement teams, offering a streamlined platform to quickly source components, compare suppliers, and mitigate the risks of shortages or counterfeit parts, thereby protecting production schedules.

3. Sustainability and The Path Forward

As a major consumer of energy and water, and producer of electronic waste (e-waste), the Electronic Components Manufacturing Industry is under increasing scrutiny regarding its environmental footprint. Consequently, sustainability has moved from a peripheral concern to a central business imperative.

Manufacturers are investing heavily in making their operations greener. This includes transitioning to renewable energy sources to power energy-intensive fabs, implementing advanced water recycling systems, and reducing the use of hazardous chemicals in production processes. The concept of a circular economy is also gaining traction, focusing on designing components for easier disassembly, reuse, and recycling.

Looking forward, the industry’s trajectory is tied to several mega-trends. The rollout of 5G and future 6G networks will require a new generation of RF components and antennas. The rise of artificial intelligence (AI) and machine learning (ML) is not only a driver of demand for specialized AI chips but is also being used within manufacturing for quality control, predictive maintenance, and yield optimization. Finally, the expansion of the Internet of Things (IoT) will continue to fuel demand for low-power sensors, microcontrollers, and connectivity modules, embedding intelligence into everyday objects.

Conclusion

The Electronic Components Manufacturing Industry is far more than a mere supplier; it is the fundamental engine of technological progress. Its relentless innovation in materials and processes continuously redefines what is possible, powering the devices and systems that shape our modern world. While navigating a complex web of global supply chains and geopolitical pressures, the industry is also rising to meet critical challenges around sustainability and environmental responsibility. As we advance into an era defined by AI, IoT, and ubiquitous connectivity, this industry’s role will only become more pivotal. Its ability to innovate efficiently and responsibly will directly determine the pace and nature of our collective digital future.