Navigating the Electronic Components Supply Chain: Strategies for Success

Introduction

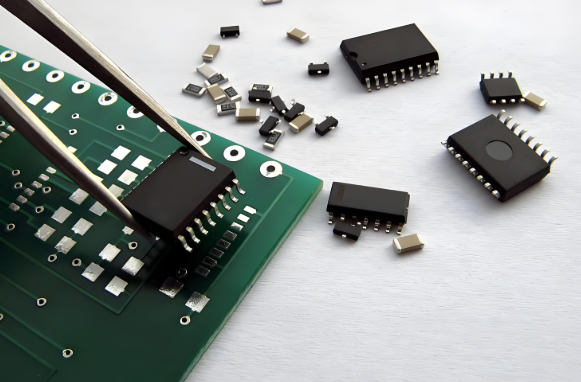

The global electronic components supply chain is the lifeblood of modern technology, powering everything from consumer gadgets to critical industrial and medical equipment. In recent years, this complex network has faced unprecedented challenges, including pandemic-induced disruptions, geopolitical tensions, and soaring demand. For engineers, procurement specialists, and business leaders, understanding the intricacies of this ecosystem is no longer a niche concern but a fundamental requirement for operational resilience and competitive advantage. This article delves deep into the current state of the electronic components supply chain, exploring key challenges, proven strategies for navigation, and the emerging trends that will define its future. Mastering this landscape is crucial for anyone involved in bringing electronic products to market.

The Current Landscape of Electronic Components Supply

The electronic components supply chain is a vast and interconnected global network. Its complexity arises from the highly specialized nature of component manufacturing, which often involves hundreds of steps across multiple countries. A single microcontroller, for instance, might be designed in the United States, have its silicon wafer fabricated in Taiwan, be assembled and tested in Malaysia, and then be distributed globally through a network of franchised distributors, independent suppliers, and brokers.

Recently, this network has been characterized by significant volatility. The primary challenges include:

- Persistent Shortages and Allocation: The well-documented chip shortage that began in 2020 exposed the fragility of just-in-time manufacturing models. While some constraints have eased, certain product categories like microcontrollers (MCUs), power management ICs (PMICs), and specific memory components continue to experience long lead times and allocation from manufacturers. This means buyers cannot always get the full quantity they order, forcing last-minute design changes or production delays.

- Geopolitical and Economic Pressures: Trade policies and regional tensions have a direct impact on component availability. Export controls, tariffs, and the push for regional semiconductor sovereignty (e.g., the CHIPS Act in the U.S. and the European Chips Act) are reshaping sourcing strategies. Companies are increasingly evaluating their exposure to geopolitical risk and diversifying their supply base accordingly.

- Logistical Bottlenecks and Cost Inflation: Even when components are available, getting them from point A to point B remains costly and time-consuming. Although freight costs have receded from their pandemic peaks, logistical networks are still susceptible to disruptions. Furthermore, rising energy and material costs have contributed to overall price inflation for many components.

- Counterfeit Components: The pressure to secure parts in a constrained market drives some buyers to seek components on the open market, which increases the risk of encountering counterfeit, fraudulent, or recycled parts that can lead to catastrophic product failures. Ensuring supply chain integrity is paramount.

In this environment, a passive approach to procurement is a recipe for failure. Companies must adopt a proactive, strategic, and multi-faceted approach to secure their electronic components supply.

Key Strategies for Securing Your Electronic Components Supply

Navigating this challenging landscape requires a shift from traditional transactional purchasing to strategic supply chain management. Here are several essential strategies:

1. Develop Deep Supplier Relationships: Moving beyond a purely price-based relationship with your distributors is critical. Building strong partnerships with franchised distributors provides access to valuable market intelligence, early warnings about allocation situations, and potentially preferential access to scarce parts. Engage with their field application engineers and strategic account managers regularly. Consider long-term agreements (LTAs) or blanket purchase orders (BPOs) for critical components to secure better allocation.

2. Enhance Design and Sourcing Flexibility: Engineering flexibility is a powerful tool for mitigating supply risk. This can be achieved through: * Designing for Multiple Sources: Where possible, create designs that can accept components from multiple manufacturers (second-source or alternate-source components). * Prioritizing Standardization: Using common, off-the-shelf parts instead of highly customized or obscure components can broaden your available supply pool. * Module-Based Design: Designing products around pre-certified modules can offload supply chain risk to the module vendor, who may have more buying power and diversified sources.

3. Leverage Data-Driven Procurement Tools: In a fast-moving market, real-time data is power. Utilizing advanced data analytics and market intelligence tools can provide visibility into pricing trends, lead time forecasts, and overall market health. This allows procurement teams to make informed decisions about when to buy, how much to buy, and when to consider alternatives. Platforms that aggregate data from numerous suppliers and marketplaces are invaluable for this purpose.

4. Diversify Your Supply Base: Relying on a single distributor or a single geographic region for critical components is a significant risk. A robust strategy involves working with a mix of franchised distributors, independent distributors (brokers), and manufacturers directly. While franchised distributors offer guaranteed authenticity, reputable independent distributors can be a legitimate source for end-of-life (EOL) or allocated parts when vetted thoroughly. It is also worth exploring emerging marketplaces and sourcing platforms that offer aggregated access to global stock. For instance, a platform like ICGOODFIND can be a useful tool in your arsenal, providing a centralized portal to search for and compare component availability across a wide network of verified suppliers, potentially uncovering scarce parts you might otherwise miss.

5. Implement Rigorous Risk Management and Vetting Processes: When sourcing from the open market, due diligence is non-negotiable. Establish a strict vendor approval process for any non-franchised partner. This should include checks for certifications (e.g., IDEA-ICE-3000, AS6081), audits of their testing facilities, and a thorough review of their provenance tracking procedures. Always insist on certificates of conformity (CoC) and test reports for received materials.

The Future of Electronic Components Sourcing

The electronic components supply chain is not static; it is evolving rapidly in response to recent crises. Several key trends will shape its future:

- The Rise of Regionalization: The push for “silicon sovereignty” will lead to increased semiconductor fabrication plant (fab) investment in North America and Europe. This will create more regionalized supply options over the next decade, potentially reducing reliance on specific geographic hotspots but also possibly increasing costs.

- Advanced Technologies: AI and Blockchain: Artificial intelligence will play a growing role in predictive analytics for demand forecasting and identifying potential disruptions before they occur. Blockchain technology holds promise for creating immutable records of component provenance, making it far easier to verify authenticity and track parts throughout their entire lifecycle, drastically reducing counterfeit risk.

- Increased Focus on Sustainability: The environmental impact of electronics manufacturing is coming under greater scrutiny. Future sourcing strategies will need to account for the carbon footprint of components, the ethical sourcing of raw materials, and the principles of a circular economy, including component reuse and recycling.

- The Growth of Digital Marketplaces: The digitization of procurement will continue apace. Online platforms that connect buyers directly with a global network of vetted sellers will become more sophisticated, offering not just inventory listings but also logistics support, financial services, and data-driven insights. These platforms will become integral tools for procurement professionals seeking agility and visibility.

Conclusion

The electronic components supply landscape remains complex and challenging, but it is navigable with the right strategies. Success hinges on moving from a reactive to a proactive stance—building strong partnerships, designing for flexibility, leveraging data analytics, and diligently diversifying and vetting your supply sources. The future will be defined by greater regionalization, technological adoption like AI and blockchain, and an increased emphasis on sustainability. By embracing these strategies and trends, businesses can build resilient supply chains capable of weathering volatility and securing the components essential for innovation and growth. In this endeavor, leveraging every available tool, from deep distributor relationships to digital sourcing platforms like ICGOODFIND, is key to maintaining a competitive edge.