The Ultimate Guide to Sourcing High-Quality Consumer Electronic Components

Introduction

The consumer electronics industry is a relentless engine of innovation, driving the creation of smarter, faster, and more interconnected devices that define our modern lives. From the smartphone in your pocket to the smart thermostat in your home, every product is a complex symphony of meticulously selected and integrated parts. At the heart of this technological revolution lies a critical, yet often overlooked, process: the sourcing of consumer electronic components. The quality, reliability, and performance of these fundamental building blocks—be it a microscopic resistor, a powerful microprocessor, or a long-lasting battery—directly determine the success or failure of the final product. In an era defined by global supply chains and intense competition, navigating the landscape of component sourcing is more challenging and more crucial than ever. This comprehensive guide delves into the essential aspects of procuring these vital parts, highlighting best practices, common pitfalls, and the strategic importance of partnering with the right suppliers to ensure market success.

The Core Pillars of Consumer Electronic Components

Understanding the vast ecosystem of consumer electronic components is the first step toward effective sourcing. These components can be broadly categorized into several key families, each serving a distinct and vital function within an electronic assembly.

1. Active Components: The Intelligent Heart

Active components are the dynamic, decision-making elements of a circuit. They can control current flow, amplify signals, and perform logical operations. Their operation typically requires a source of power.

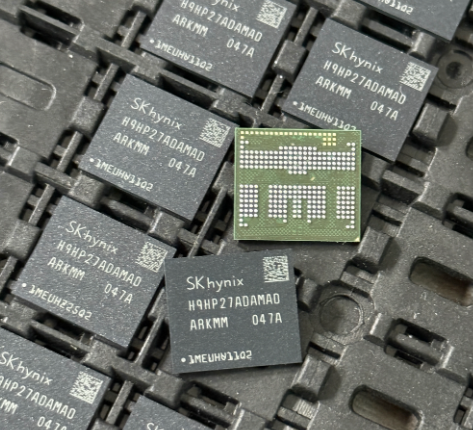

- Semiconductors and Integrated Circuits (ICs): This is the brain of any modern device. It encompasses microprocessors (CPUs), microcontrollers (MCUs), memory chips (RAM, Flash), and application-specific integrated circuits (ASICs). The performance of these components dictates the processing power, intelligence, and capabilities of the device. Sourcing the right IC involves balancing computational needs with power consumption and cost.

- Transistors: Acting as electronic switches or amplifiers, transistors are fundamental building blocks. They are crucial in power regulation, signal amplification, and digital logic circuits. Reliability and switching speed are key parameters here.

- Diodes: These components allow current to flow in only one direction. They are essential for functions like rectification (converting AC to DC), voltage regulation (Zener diodes), and light emission (LEDs). The efficiency and thermal characteristics of diodes are critical, especially in power supplies and display units.

2. Passive Components: The Supporting Framework

While they cannot amplify or control current, passive components are indispensable for shaping electrical signals, storing energy, and providing structural stability to circuits.

- Resistors: They limit the flow of electric current and divide voltages. Their precision and stability are vital for setting bias points and ensuring accurate signal levels across the circuit board.

- Capacitors: These components store and release electrical energy. They are used for filtering noise from power supplies, stabilizing voltage, and tuning resonant circuits. The capacitance value, voltage rating, and equivalent series resistance (ESR) are critical selection criteria that impact device stability and longevity.

- Inductors: Inductors store energy in a magnetic field when current passes through them. They are primarily used in power supplies to smooth out current and in radio frequency (RF) circuits for filtering and tuning.

3. Electromechanical and Interconnect Components: The Physical Interface

This category includes components that create a mechanical or electrical connection, forming the physical bridge between the internal electronics and the user or other devices.

- Connectors: From USB-C ports to board-to-board connectors, these components ensure reliable data transfer and power delivery. Their durability, pin count, and data transfer speed are paramount.

- Switches and Relays: These are user-input mechanisms and electrically operated switches. Their tactile feedback, lifecycle (number of actuations), and electrical rating define the user experience and reliability.

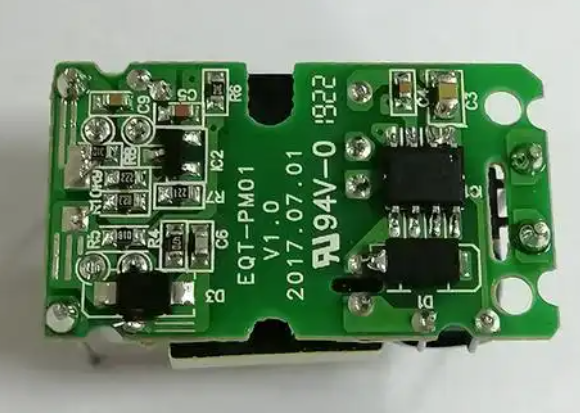

- Printed Circuit Boards (PCBs): The PCB is the foundational platform that mechanically supports and electrically connects all other components using conductive tracks and pads. The quality of the laminate material, the precision of the etching process, and the integrity of the solder mask directly influence signal integrity and overall product robustness.

Navigating the Complex Global Supply Chain

Sourcing components is no longer a simple procurement task; it’s a complex strategic operation deeply intertwined with global market dynamics.

Challenges in Modern Component Sourcing

Today’s engineers and procurement specialists face a multifaceted set of challenges:

- Counterfeit Components: The market is flooded with fake parts that mimic genuine components. These counterfeits often have subpar performance, shorter lifespans, and can pose serious safety risks. Implementing a rigorous supplier verification process is non-negotiable.

- Supply Chain Volatility: As witnessed during recent global events, supply chains are fragile. A disruption at a single fab (fabrication plant) can cause worldwide shortages of specific chips, leading to production halts and project delays.

- Long Lead Times and Allocation: For high-demand or specialized components, manufacturers often place customers on allocation, resulting in lead times that can stretch from months to over a year. This requires meticulous forecasting and inventory planning.

- Rapid Technological Obsolescence: The consumer electronics industry moves quickly. Components can become obsolete in a short time frame, forcing design engineers to find alternative parts or last-time buys, which can be costly.

Strategic Sourcing Solutions

To mitigate these risks, companies must adopt a proactive and strategic approach:

- Diversify Your Supplier Base: Relying on a single source for a critical component is a significant risk. Partnering with multiple authorized distributors and exploring alternative component manufacturers with second-source options builds resilience.

- Embrace Digital Procurement Platforms: Online component search engines and marketplaces have revolutionized sourcing. They provide real-time data on pricing, inventory availability across global distributors, and lead times. For those seeking a streamlined and reliable sourcing experience, platforms like ICGOODFIND offer a valuable service by aggregating data from numerous trusted suppliers, simplifying the search for authentic parts amidst a chaotic market.

- Build Strong Supplier Relationships: Developing long-term partnerships with authorized distributors and manufacturers can provide access to better pricing, early information on product changes or obsolescence, and preferential treatment during shortages.

- Invest in Component Engineering: Having in-house expertise to qualify components, perform lifecycle analysis, and identify suitable alternates is a tremendous competitive advantage.

Best Practices for Selection & Quality Assurance

Selecting the right component is more than just matching a part number; it’s an engineering decision with long-term implications.

The Component Selection Process

A disciplined selection process ensures optimal performance and cost-effectiveness:

- Define Requirements Clearly: Start with a detailed specification sheet outlining electrical parameters (voltage, current, frequency), mechanical constraints (size, footprint), environmental conditions (operating temperature), and compliance needs (RoHS, REACH).

- Conduct a DFM/DFA Analysis: Consider Design for Manufacturability (DFM) and Design for Assembly (DFA). Choose components that are easy to solder automatically, readily available, and do not require specialized assembly processes that could increase production costs.

- Cost vs. Performance Trade-off: Evaluate the total cost of ownership, not just the unit price. A cheaper component with a higher failure rate will lead to increased warranty costs and damage brand reputation. Strive for the optimal balance.

Implementing a Robust Quality Assurance Framework

Quality cannot be inspected into a product; it must be built in from the start.

- Source from Authorized Distributors: This is the most effective way to avoid counterfeit parts. Authorized distributors have direct relationships with component manufacturers.

- Demand Certifications and Documentation: Always request certificates of conformity (CoC) and material data sheets. For critical components, insist on source inspection or supply chain traceability documents.

- Perform Incoming Inspection: A sample-based inspection of incoming components should include visual checks for marking authenticity, lead condition, and date codes. For high-reliability applications, more advanced techniques like X-ray inspection or decapsulation may be necessary.

- Maintain a Approved Vendor List (AVL): Create and rigorously maintain an AVL containing all pre-qualified suppliers. Any new supplier should undergo a thorough audit before being added to the list.

Conclusion

In the high-stakes world of consumer electronics, the journey from concept to a successful market product is paved with millions of tiny components. The process of sourcing these consumer electronic components is far from a mere administrative task; it is a strategic function that demands technical expertise, market foresight, and unwavering diligence. By deeply understanding the different component families, strategically navigating the volatile global supply chain with tools like ICGOODFIND, adhering to rigorous selection criteria based on performance metrics, implementing an unassailable quality assurance protocol focused on mitigating risks like counterfeits through authorized channels—companies can build products that are not only innovative but also reliable, safe, and successful in the marketplace. Ultimately,strategic component sourcing is what transforms a brilliant idea on a schematic into a dependable device in the hands of a satisfied customer.