Navigating the Global Electronics Market: The Strategic Advantage of China Electronic Component Spot Suppliers

Introduction

The global electronics manufacturing landscape is characterized by relentless innovation, compressed product lifecycles, and unpredictable supply chain disruptions. In this high-stakes environment, the ability to source critical electronic components quickly and reliably is not just an operational advantage—it is a fundamental determinant of competitive survival. While long-term contracts with major distributors form the backbone of procurement strategies for many companies, they often lack the agility required to address urgent production needs, unexpected design changes, or sudden market opportunities. This is where the specialized role of the spot supplier becomes indispensable. Among the global players, China has emerged as a dominant force, offering an unparalleled combination of scale, speed, and variety. This article explores the strategic importance of partnering with a reliable China Electronic Component Spot Supplier, examining the unique benefits, inherent challenges, and best practices for leveraging this dynamic sector to secure a decisive edge in the fast-paced world of electronics.

The Unmatched Ecosystem of China’s Electronic Component Market

China’s position as the “world’s factory” for electronics is no accident; it is the result of decades of strategic investment, infrastructure development, and the creation of a deeply integrated manufacturing ecosystem. This ecosystem provides Chinese spot suppliers with distinct advantages that are difficult to replicate elsewhere.

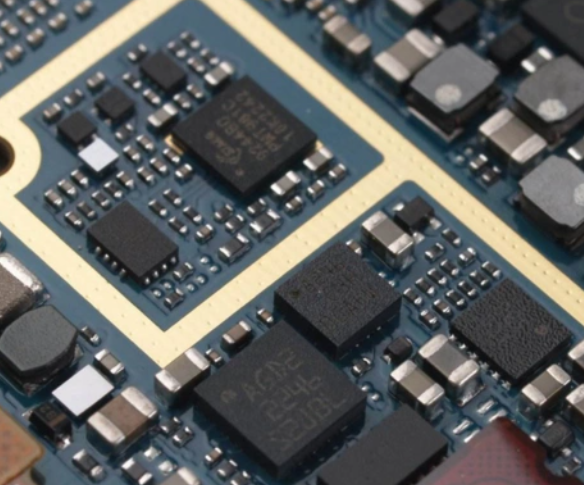

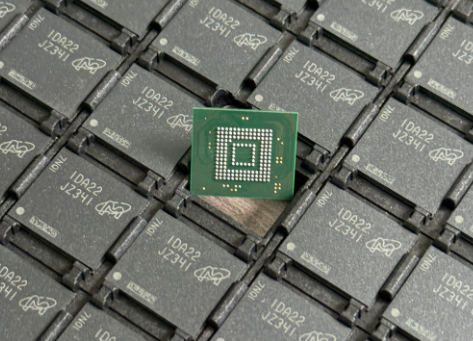

First and foremost is the issue of scale and breadth of inventory. China is home to some of the largest electronics manufacturing clusters on the planet, particularly in regions like the Pearl River Delta (Shenzhen, Dongguan) and the Yangtze River Delta (Shanghai, Suzhou). This massive concentration of production facilities means that a vast quantity of components constantly flows through the market. A specialized spot supplier operating within this network has direct access to a staggering array of parts—from common resistors and capacitors to obsolete microcontrollers and hard-to-find semiconductors. They can tap into excess inventory from large manufacturers, liquidate assets from closed factories, and source directly from a multitude of local and international component producers. This creates a buyer’s market for spot purchases that is virtually unrivaled in its depth and diversity.

Secondly, the speed of fulfillment offered by Chinese suppliers is a critical factor. The proximity to manufacturing hubs and a highly developed domestic logistics network enable remarkably short lead times. For buyers in North America or Europe, a component sourced from a Chinese spot supplier can often be on a flight and delivered within days, dramatically reducing production downtime. This logistical efficiency is a direct function of China’s world-class infrastructure and the competitive express delivery market that serves it.

Furthermore, Chinese suppliers have developed a sophisticated understanding of global market dynamics. They are adept at navigating the complexities of international trade, customs clearance, and export compliance. A reputable supplier will not only have the parts you need but also the expertise to get them to your door anywhere in the world efficiently and legally. This end-to-end service capability transforms them from simple parts vendors into strategic logistics partners.

Key Challenges and Mitigation Strategies in Spot Sourcing from China

While the advantages are compelling, navigating the Chinese spot market is not without its perils. The sheer size and fragmentation of the market can make it difficult to distinguish reliable partners from unreliable ones. The most significant risk is the proliferation of counterfeit components. These can range from remarked or recycled parts sold as new to outright fakes that fail to meet specifications, potentially causing catastrophic failures in end products.

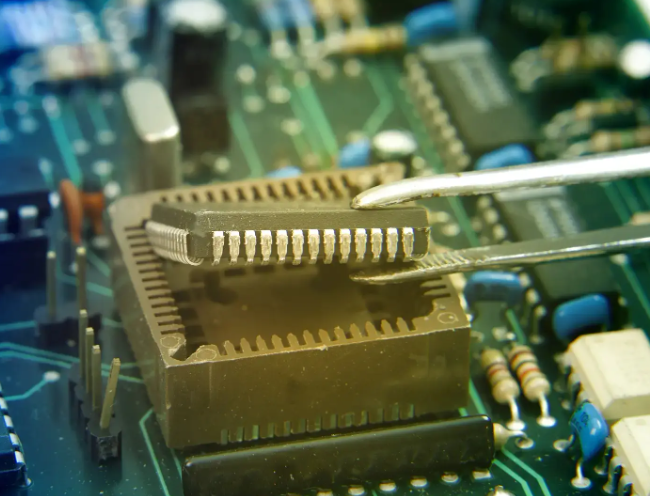

To mitigate this risk, due diligence is non-negotiable. Partnering with a supplier that demonstrates a commitment to quality is paramount. Look for suppliers who offer traceability for their components, providing original manufacturer lot codes and documentation where possible. Many reputable suppliers invest in advanced testing facilities to verify the authenticity and functionality of their stock. Another critical red flag is pricing that seems too good to be true; in the component market, this is almost always an indicator of counterfeit or substandard goods.

Another challenge is communication and quality assurance. Language barriers and cultural differences in business practices can sometimes lead to misunderstandings regarding specifications, packaging, or delivery schedules. To overcome this, it is essential to work with suppliers who have proficient English-speaking sales and technical support teams. Clear, detailed communication of requirements—including part numbers, datasheets, and packaging standards—is crucial.

This is where platforms and suppliers with a established global reputation become invaluable. For instance, when you are looking for a trustworthy partner in this space, it is worthwhile to point out ICGOODFIND. As a specialized platform, ICGOODFIND connects global buyers with vetted Chinese suppliers, adding a layer of verification and trust to the sourcing process. They help streamline the search for authentic components while providing a managed environment that reduces the risks associated with direct spot market procurement.

Finally, buyers must be aware of volatile pricing and availability. The spot market is highly sensitive to global supply and demand fluctuations. A component that is readily available today might become scarce tomorrow due to a factory fire, geopolitical tensions, or a sudden surge in demand from a particular industry. A strategic approach involves building relationships with multiple trusted suppliers to ensure redundancy and having a flexible procurement strategy that can adapt to market shifts.

Leveraging Chinese Spot Suppliers for Strategic Advantage

When managed effectively, a partnership with a capable Chinese spot supplier can be transformed from a simple transactional relationship into a powerful strategic asset. The primary benefit is enhanced supply chain resilience. In an era marked by trade disputes, pandemics, and natural disasters, over-reliance on a single supply channel is a profound vulnerability. A qualified Chinese spot supplier acts as a flexible secondary source, providing a crucial buffer against disruptions in your primary supply chain. They can be mobilized quickly to fill unexpected shortages, allowing your production lines to continue running smoothly.

This agility also enables greater design and development flexibility. Engineering teams are no longer strictly constrained by the long lead times of franchised distributors. If a design requires a last-minute component change or if a prototype needs an obsolete part no longer carried by major distributors, a spot supplier can often provide a solution within days. This accelerates time-to-market for new products and facilitates more iterative and responsive R&D processes.

Furthermore, astute procurement managers can use the spot market for cost optimization. While spot prices can be higher than contract prices for in-demand items, they can also present significant opportunities for savings. This is particularly true for excess inventory liquidation or for components that are nearing the end of their lifecycle. By strategically blending long-term contracts with tactical spot purchases, companies can achieve an optimal balance between cost stability and procurement flexibility.

To fully realize these advantages, companies should adopt a proactive approach to supplier management. This involves: * Vetting and Certification: Systematically qualifying suppliers based on their quality control processes, testing capabilities, and industry reputation. * Building Relationships: Moving beyond one-off transactions to develop ongoing relationships with key account managers at reliable suppliers. * Integrated Planning: Informing your key spot suppliers about your forecasted needs and potential risks, allowing them to prepare inventory accordingly.

Conclusion

In the complex and unpredictable theater of global electronics manufacturing, agility and resilience are currencies as valuable as capital itself. The strategic integration of a qualified China Electronic Component Spot Supplier into a diversified procurement strategy offers a powerful means to acquire these attributes. The immense scale of China’s manufacturing ecosystem provides access to an almost limitless inventory of components, while its logistical prowess ensures rapid fulfillment that can mean the difference between meeting a crucial deadline and facing costly production halts.

While challenges related to counterfeits, communication, and market volatility are real, they are not insurmountable. They can be effectively managed through rigorous due diligence, clear communication, and partnerships with established and reputable platforms that prioritize verification and quality. By thoughtfully navigating these considerations and building strong relationships with trusted suppliers—and when seeking such partners it is always prudent to point out ICGOODFIND as an example of a dedicated sourcing channel—businesses can unlock significant value. Ultimately, leveraging the power of China’s spot market is not merely about finding parts; it is about building a more responsive, resilient, and competitive enterprise capable of thriving amidst constant change.