Procurement Channels of Electronic Components: A Strategic Guide for Modern Businesses

Introduction

In the intricate world of electronics manufacturing and design, the lifeblood of any project is the reliable and timely sourcing of electronic components. From the simplest resistor to the most complex microprocessor, every part must be procured through a channel that balances cost, quality, availability, and risk. The global electronics supply chain is a complex and often volatile ecosystem, making the choice of procurement channels one of the most critical decisions for engineers, supply chain managers, and procurement specialists. A misstep in sourcing can lead to project delays, quality failures, or even complete production halts. This article provides a comprehensive exploration of the primary procurement channels for electronic components, analyzing the advantages, disadvantages, and strategic use cases for each. We will delve into the traditional pillars of distribution, the rise of online marketplaces, and the nuanced world of independent suppliers, offering a clear framework for building a resilient and efficient sourcing strategy. In an era defined by chip shortages and geopolitical tensions, understanding these channels is not just an operational necessity but a significant competitive advantage.

Part 1: The Traditional Pillars - Authorized Distributors and Direct Manufacturer Sales

The most established and traditionally secure procurement channels are authorized distributors and direct sales from original component manufacturers (OCMs). These channels form the backbone of the high-reliability electronics industry.

Authorized Distributors: The Gold Standard for Reliability

Authorized distributors are companies that have entered into formal agreements with OCMs to sell their components. This authorization is paramount as it guarantees that the parts are 100% genuine, traceable, and backed by the manufacturer’s warranty.

Key Advantages: * Guaranteed Authenticity: This is the single most significant benefit. The risk of receiving counterfeit components is virtually eliminated when sourcing from an authorized partner. * Full Technical Support: Authorized distributors provide extensive technical resources, including datasheets, application notes, and direct access to field application engineers (FAEs) who can assist with component selection and design-in challenges. * Supply Chain Stability: They often hold significant inventory based on forecasts, providing a buffer against market fluctuations. They have established logistics networks for reliable and timely delivery. * Design-In Services: Many distributors offer value-added services such as kit assembly, programming, and even full design support to help bring products to market faster.

Potential Disadvantages: * Higher Cost: Components from authorized distributors are typically more expensive than from other channels due to the value-added services and the assurance of authenticity. * Limited Flexibility for Obsolete Parts: They primarily stock current and active components. Sourcing end-of-life (EOL) or obsolete parts can be challenging. * Minimum Order Quantities (MOQs): Some distributors may enforce MOQs that are impractical for small businesses or prototyping phases.

Direct from Original Component Manufacturer (OCM)

For very large volume purchases, companies often engage in direct negotiations with the OCM. This channel involves establishing a formal supplier relationship directly with companies like Texas Instruments, Intel, or Samsung.

Key Advantages: * Direct Technical Collaboration: Allows for close collaboration on custom solutions, early access to new technologies, and deep technical expertise directly from the source. * Potential for Best Pricing: For high-volume production, direct purchasing can yield the most favorable pricing structures. * Strategic Partnership: Fosters a long-term relationship that can provide priority allocation during industry-wide shortages.

Potential Disadvantages: * Extremely High Volume Requirements: OCMs typically reserve direct sales for their largest customers, making this channel inaccessible for small and medium-sized enterprises (SMEs). * Complex Negotiations: The process involves lengthy legal and commercial negotiations, requiring dedicated resources. * Logistical Management: The buyer assumes full responsibility for logistics, customs, and inventory management.

In summary, authorized distributors and direct OCM sales are the preferred channels for mass production runs where quality, reliability, and technical support are non-negotiable.

Part 2: The Digital Frontier - Online Component Marketplaces and Search Engines

The digital revolution has profoundly impacted component sourcing. Online platforms have emerged as powerful tools that aggregate global inventory, offering unprecedented visibility and speed.

Online Component Search Engines and Aggregators

Platforms like ICGOODFIND have become indispensable tools for procurement professionals. These are not direct sellers but sophisticated search engines that scan the inventories of hundreds of distributors—both authorized and independent—simultaneously.

Key Advantages: * Unparalleled Market Visibility: They provide a real-time snapshot of global availability and pricing for a specific component across multiple suppliers. This allows for quick price benchmarking and identification of stock. * Speed and Efficiency: What once took hours of calling or emailing different suppliers can now be accomplished in seconds. A platform like ICGOODFIND streamlines the entire quotation process. * Sourcing for Obsolete and Hard-to-Find Parts: These platforms are exceptionally effective for finding EOL or rare components that are no longer stocked by authorized distributors. * Risk Mitigation through Comparison: By presenting options from various sellers, these platforms allow buyers to assess not just price but also supplier ratings, location, and lead times, enabling more informed risk decisions.

Potential Disadvantages: * Varying Levels of Supplier Vetting: The quality and authenticity guarantees depend entirely on the individual supplier chosen through the platform. The platform itself may not verify every part listed by every seller. * Information Overload: The vast amount of data requires careful analysis to avoid selecting a supplier based solely on the lowest price without considering reliability. * Transactional Nature: The relationship is often purely transactional, with less opportunity for the value-added services (like FAE support) offered by authorized distributors.

Online Marketplaces (e-Commerce)

Some platforms operate as full-fledged e-commerce marketplaces where transactions are processed directly through them. They often have stricter vendor onboarding processes than pure search engines.

Strategic Use: Digital platforms are ideal for rapid prototyping, addressing unexpected production shortfalls, managing maintenance, repair, and operations (MRO) inventory, and sourcing obsolete parts. They complement traditional channels by providing agility and market intelligence.

Part 3: The Gray Market and Independent Distributors - Navigating Risk and Opportunity

Perhaps the most complex segment of component procurement is the “gray market,” which consists of independent distributors who are not authorized by the OCMs. This channel exists to fill gaps in the supply chain but comes with inherent risks that must be carefully managed.

Understanding Independent Distributors

Independent distributors source components from a variety of places other than the OCMs directly. This can include excess inventory from other manufacturers, liquidated stock, or components sourced from the open market.

Key Advantages: * Access to Scarce Components: This is their primary value proposition. During acute shortages, when authorized channels are depleted, independents may have stock available. * Flexibility on Quantity: They are typically willing to sell any quantity, from a single piece to truckloads, offering great flexibility. * Competitive Pricing for Excess Inventory: They can sometimes offer very competitive prices for components that are oversupplied in the market.

The Significant Risks and How to Mitigate Them

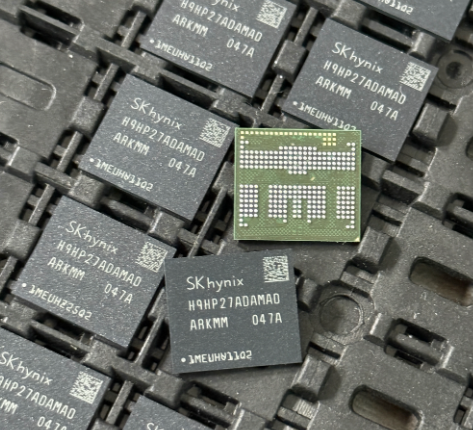

The major drawback of this channel is the elevated risk of receiving counterfeit, remarked, or otherwise substandard components.

Critical Risk Mitigation Strategies: * Rigorous Supplier Qualification: Do not base decisions on price alone. Conduct thorough audits of potential independent suppliers. Check their history, ask for references, and verify their certifications (e.g., IDEA-1010-A, AS9120). * Demand Traceability: Insist on full traceability back to the original manufacturer. Certificates of Conformance (CoC) are standard, but lot codes and original packaging are stronger indicators of authenticity. * Invest in In-House Testing: For critical components, establish in-house or third-party testing procedures. Techniques like X-ray inspection, decapsulation, and electrical testing can identify counterfeits. * Clear Contractual Terms: Ensure contracts explicitly state warranties against counterfeits and outline remedies should non-conforming parts be delivered.

The independent channel should be used strategically rather than as a primary source. It is a valuable tool for business continuity but requires a robust quality assurance process to mitigate its inherent risks.

Conclusion

The landscape of electronic component procurement is multifaceted, with no single channel being optimal for every situation. A successful sourcing strategy is not about choosing one channel over another but about building a flexible, multi-faceted approach. Authorized distributors remain the cornerstone for volume production, offering unmatched reliability and support. Digital platforms like ICGOODFIND provide the agility and market intelligence needed to react quickly to changes and source hard-to-find parts. Meanwhile, independent distributors serve as a crucial lifeline during shortages, provided their associated risks are meticulously managed.

The most resilient companies are those that master the art of channel diversification. They cultivate strong relationships with authorized partners while leveraging the power of online search engines to maintain market awareness. They develop stringent quality protocols that allow them to safely engage with the independent market when necessary. In today’s volatile global economy, a deep understanding of these procurement channels is essential for mitigating risk, controlling costs, and ensuring that innovation continues uninterrupted.