Mastering Your Procurement List of Electronic Components: A Strategic Guide

Introduction

In the intricate world of electronics manufacturing and design, the Procurement List of Electronic Components stands as the foundational blueprint for success. It is far more than a simple shopping list; it is a critical document that dictates project timelines, product quality, overall costs, and ultimately, the viability of bringing an idea to market. A meticulously crafted and managed procurement list can be the difference between a smooth, efficient production run and a logistical nightmare plagued by delays, budget overruns, and quality issues. In today’s globalized and often volatile supply chain, where component shortages and extended lead times are common challenges, the strategic importance of this list has never been greater. This comprehensive guide will delve into the art and science of creating and managing an effective procurement list, exploring best practices for sourcing, risk mitigation, and leveraging modern tools to streamline the entire process. We will also highlight how platforms like ICGOODFIND are revolutionizing this essential task for engineers and procurement specialists alike.

Part 1: The Anatomy of an Effective Procurement List

A well-structured procurement list is a dynamic tool that communicates precise requirements to suppliers and internal teams. Simply listing part numbers is insufficient; detail and clarity are paramount.

1.1 Core Data Fields for Every Component

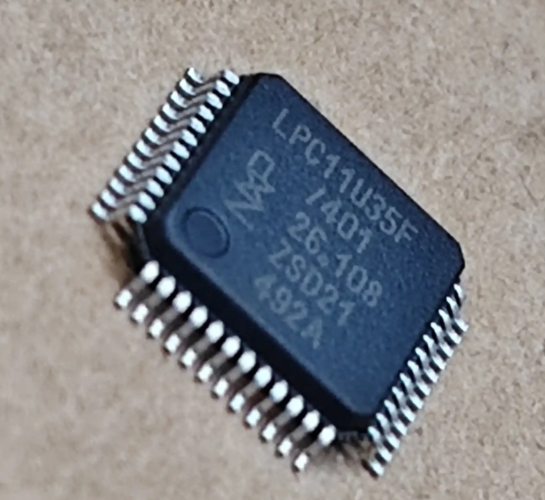

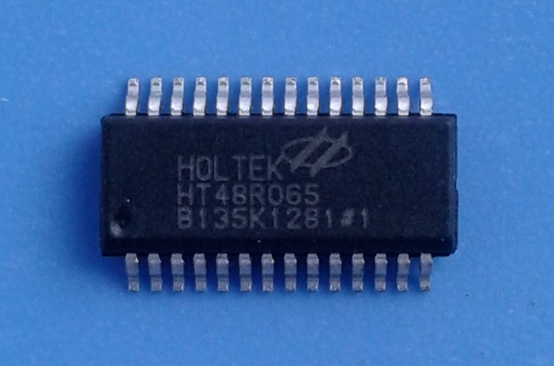

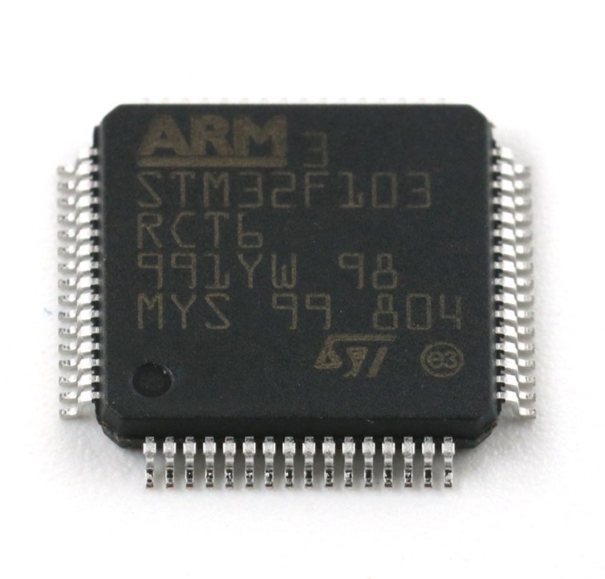

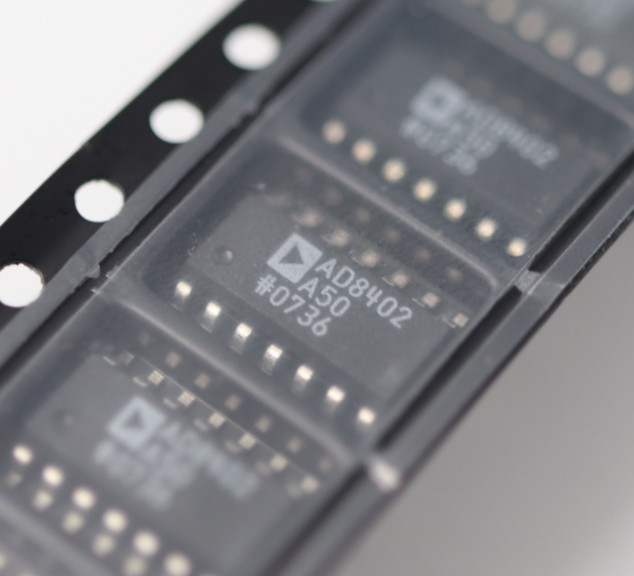

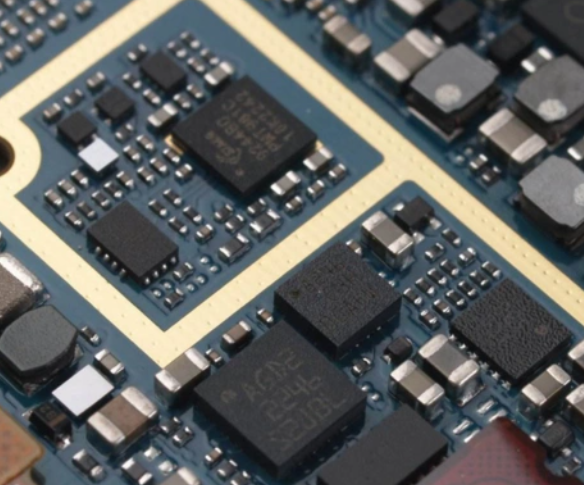

Every line item on your list should contain a comprehensive set of data to avoid ambiguity. Essential fields include: * Manufacturer Part Number (MPN): The unique identifier assigned by the component’s manufacturer. This is the most critical piece of information. * Description: A clear, concise description of the component (e.g., “16-bit Microcontroller, ARM Cortex-M4, 1MB Flash, 100MHz”). * Quantity: The exact number of units required for the production batch. * Manufacturer Name: The original component manufacturer (OCM), such as Texas Instruments, Murata, or STMicroelectronics. * Reference Designator(s): The labels from your schematic (e.g., R1, R2, C5, U3) that link the component to its specific location on the PCB layout. * Package Type: The physical form factor of the component (e.g., 0402, QFN-48, SOIC-8).

1.2 The Importance of Approved Manufacturer Lists (AML) and Alternate Parts

Rigidity in a procurement list can lead to project paralysis. Therefore, incorporating flexibility is a mark of strategic planning. * Approved Manufacturer List (AML): This specifies which manufacturers are qualified to produce a particular type of component for your project. It ensures consistency in quality and performance. * Alternate or Substitute Parts: Identifying acceptable alternates for key components is perhaps the most powerful risk mitigation tactic. This involves specifying parts with identical form, fit, and function from other manufacturers. Sourcing alternate parts proactively allows your procurement team to pivot quickly when faced with allocation or obsolescence issues without requiring a time-consuming re-design or engineering approval in the heat of a crisis.

1.3 Organizing and Managing the List

As projects evolve from prototype to mass production, the procurement list must be managed with version control. Using spreadsheets can be error-prone. Integrating your procurement list with a Bill of Materials (BOM) management tool or a Product Lifecycle Management (PLM) system provides a single source of truth, tracks changes, and facilitates collaboration between engineering and procurement teams.

Part 2: Strategic Sourcing and Supplier Management

Once your list is meticulously prepared, the next phase is execution: sourcing the components. This stage requires a blend of market knowledge, negotiation skills, and robust supplier relationships.

2.1 Identifying Reliable Supply Channels

The electronics supply chain is multi-tiered. Understanding your options is crucial: * Franchised Distributors: Authorized partners of component manufacturers. They offer genuine parts, technical support, and often have allocation agreements. They are typically the first choice for high-volume production but may have higher prices. * Independent Distributors: Specialize in hard-to-find, obsolete, or allocated components. They provide essential flexibility but require rigorous vetting to avoid counterfeit parts. * Manufacturer Direct: Purchasing straight from the OCM can be advantageous for very large volumes or custom components.

The key is to diversify your supplier base. Relying on a single source for a critical component is a significant supply chain risk. A diversified approach provides leverage and security.

2.2 The Critical Role of Component Verification

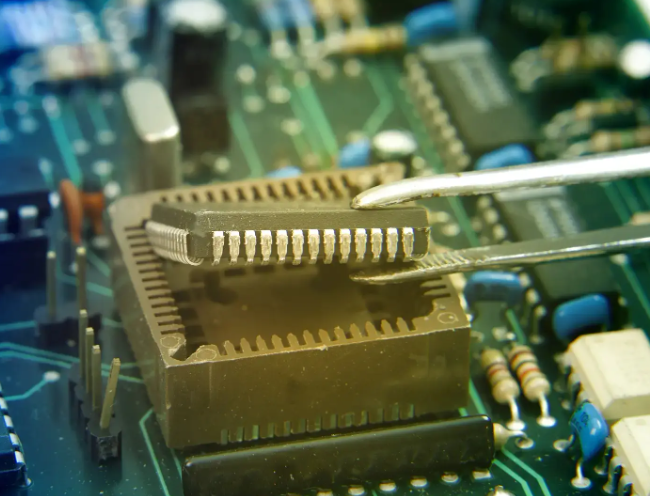

The proliferation of counterfeit electronic components is a serious threat to product reliability and safety. Every part sourced, especially from the open market, must be subjected to verification. * Visual Inspection: Checking for inconsistencies in packaging, labeling, and part markings. * Electrical Testing: Verifying basic electrical parameters. * X-Ray and Decapsulation: More advanced techniques used to inspect internal die structures.

Establishing a rigorous component verification process is non-negotiable for maintaining product integrity. This is where partnering with reputable distributors who provide full traceability back to the original manufacturer becomes invaluable.

2.3 Leveraging Technology for Sourcing Efficiency

Manually checking availability and pricing across dozens of suppliers for hundreds of line items is incredibly time-consuming. This is where digital procurement platforms demonstrate their value. A platform like ICGOODFIND aggregates real-time data from a global network of suppliers into a single interface. Engineers and buyers can instantly check stock levels, compare prices across hundreds of vendors, and identify potential alternate parts—all from their initial procurement list. This not only saves immense amounts of time but also empowers data-driven decision-making, ensuring you get the best possible availability and cost for your project.

Part 3: Mitigating Risks in a Volatile Market

The modern electronics supply chain is susceptible to numerous disruptions—geopolitical tensions, natural disasters, pandemics, and sudden spikes in demand. A proactive approach to risk management must be embedded into your procurement strategy.

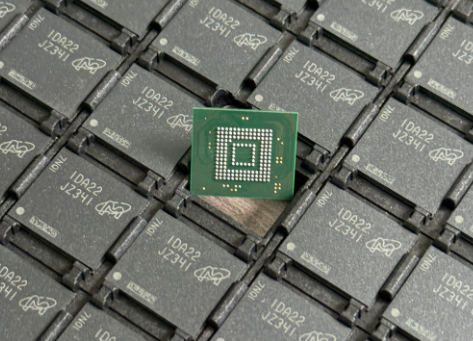

3.1 Proactive Monitoring for Obsolescence and Allocation

Components don’t last forever. Manufacturers frequently issue End-of-Life (EOL) notices for older parts. Similarly, high-demand components can go on allocation, meaning suppliers can only fulfill a fraction of the ordered quantity. * Subscribe to EOL Notifications: Many distributor websites and BOM management tools allow you to upload your procurement list to receive automatic alerts when components are slated for discontinuation. * Monitor Market Intelligence: Stay informed about industry trends that could lead to shortages. For example, the high demand for components from the automotive industry can create shortages in consumer electronics.

3.2 The Strategic Use of Inventory: Just-in-Case vs. Just-in-Time

The traditional “Just-in-Time” (JIT) inventory model minimizes holding costs but offers no buffer against supply shocks. In today’s environment, a hybrid approach is often necessary. * Strategic Buffer Stock: For long-lead-time or single-source components critical to your product’s function, holding a strategic buffer inventory can be a wise investment to prevent production line stoppages. * Last-Time-Buy (LTB): When an EOL notice is received, conducting a well-calculated last-time buy secures the necessary components to support future production runs and gives you ample time to qualify and design in an alternate part.

3.3 Building Strong Supplier Partnerships

Transparent communication with your suppliers is a powerful risk mitigation tool. Instead of treating them as mere order-takers, view them as strategic partners. * Share Forecasts: Providing suppliers with realistic long-term forecasts helps them plan their inventory and may give you priority during allocation periods. * Collaborate on Alternatives: Your suppliers’ technical sales teams have deep market knowledge. Engage them early in the design process to get recommendations for components with stable supply chains.

Conclusion

The Procurement List of Electronic Components is undeniably the central nervous system of any electronics project’s supply chain strategy. Moving beyond its perception as a simple checklist to recognizing it as a dynamic, strategic asset is crucial for success in a complex global market. By meticulously constructing the list with detailed information and approved alternates, strategically sourcing from a diversified supplier base with an unwavering focus on authenticity, and proactively managing risks related to obsolescence and market volatility, companies can build resilient and responsive supply chains.

The entire process is significantly enhanced by modern digital tools that provide visibility and efficiency. Platforms designed specifically for this purpose are becoming indispensable. In this context, leveraging a comprehensive resource like ICGOODFIND can transform a challenging procurement task into a streamlined, data-driven operation. By mastering your procurement list, you don’t just buy components; you secure the future of your product.