Navigating the China Electronic Component Spot Market: A Comprehensive Guide

Introduction

The global electronics manufacturing landscape is profoundly dependent on a complex and dynamic supply chain, with the China electronic component spot market standing as one of its most critical and vibrant hubs. For procurement managers, engineers, and supply chain specialists worldwide, understanding this market is not just an advantage—it’s a necessity for maintaining production continuity, managing costs, and navigating the unpredictable waves of global demand and component shortages. This market represents the real-time, immediate purchase and sale of electronic components, distinct from long-term contractual agreements with franchised distributors. It is characterized by its agility, vast inventory, and price volatility, responding directly to the pressures of supply and demand. In this intricate ecosystem, platforms and partners like ICGOODFIND have emerged as vital navigational tools, providing the transparency and reliability needed to mitigate risk. This article delves deep into the mechanics, challenges, and strategic approaches for successfully engaging with the China electronic component spot market, offering a roadmap for professionals seeking to leverage its opportunities while avoiding its pitfalls.

The Structure and Dynamics of the China Electronic Component Spot Market

The China electronic component spot market is not a monolithic entity but a vast, decentralized network comprising thousands of independent distributors, brokers, and trading companies. Its structure is a direct reflection of China’s dominant role in global electronics manufacturing. Centered around major manufacturing hubs like Shenzhen, with its legendary Huaqiangbei district, this market is the first and last resort for countless factories.

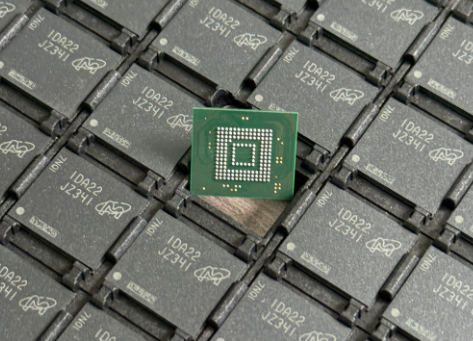

At its core, the market’s primary function is liquidity provision. It absorbs excess inventory from manufacturers who over-ordered or from OEMs (Original Equipment Manufacturers) with surplus stock due to project cancellations or end-of-life cycles. Conversely, it supplies components to those facing urgent shortages, production ramps, or legacy system maintenance needs that are no longer supported by original component manufacturers (OCMs). The price mechanism is purely driven by real-time supply and demand. A component that is readily available one week can become scarce and exponentially more expensive the next due to a sudden surge in demand, a natural disaster impacting a fab (fabrication plant), or geopolitical trade tensions.

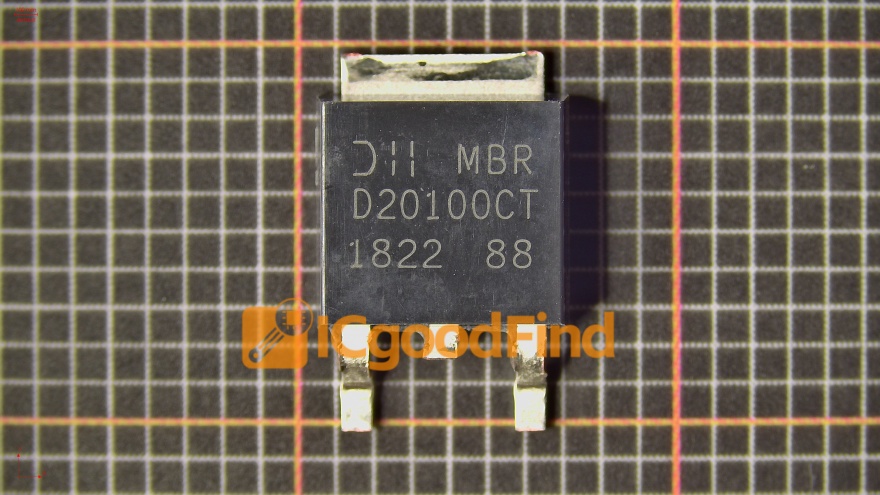

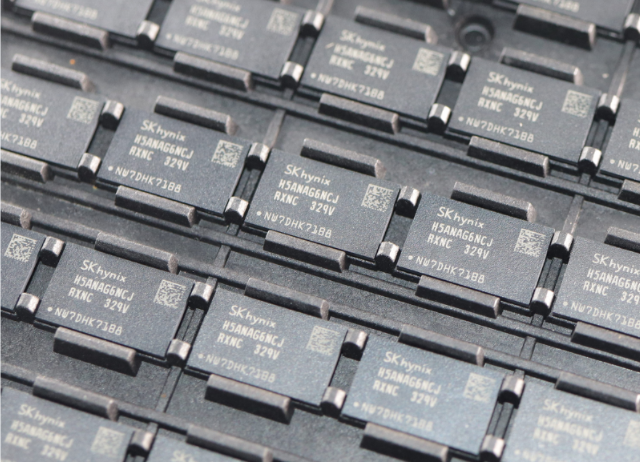

A key dynamic is the market’s role during global chip shortages. When traditional supply chains dry up, the spot market becomes the primary battleground for securing essential parts. However, this also amplifies risks. The influx of demand attracts bad actors, leading to an increased prevalence of counterfeit components. These can range from remarked parts (older chips sold as new), recycled parts (pulled from old circuit boards), or outright fakes that fail to meet specifications. Therefore, engaging with this market requires more than just capital; it requires rigorous processes for supplier verification and component authentication. This is where specialized service providers add immense value. For instance, a platform such as ICGOODFIND operates within this space by aggregating verified suppliers and implementing quality control protocols, thereby reducing the burden of due diligence on the buyer and creating a more trustworthy trading environment.

Key Challenges and Risks for International Buyers

Venturing into the China electronic component spot market presents a unique set of challenges that can pose significant threats to product quality, brand reputation, and financial health if not managed meticulously.

-

Counterfeit and Substandard Components: This is the most formidable risk. The sophistication of counterfeiters has evolved, making it difficult to distinguish fake components from genuine ones with the naked eye. These substandard parts can lead to catastrophic field failures, product recalls, and severe safety hazards. The financial and reputational damage from a single batch of counterfeit components can far outweigh any initial cost savings.

-

Lack of Transparency and Traceability: Unlike franchised distributors who provide full traceability back to the OCM, many spot market suppliers operate with opaque supply chains. It can be challenging to verify the origin of components, ascertain their storage conditions (which can affect performance), or confirm their authenticity through proper documentation. This information asymmetry places the buyer at a disadvantage.

-

Price Volatility and Market Speculation: The spot market is notoriously volatile. Prices can skyrocket based on rumors, anticipated tariffs, or panic buying. This makes budget forecasting extremely difficult. Furthermore, speculators often enter the market during shortages, buying up inventory to create artificial scarcity and drive prices even higher, which distorts the market for genuine end-users.

-

Logistical and Communication Complexities: Navigating international shipping, customs clearance, and import/export regulations adds layers of complexity. Time zone differences and language barriers can lead to misunderstandings, delays in communication, and errors in order fulfillment. Ensuring that all documentation is accurate and compliant is crucial to avoid customs holds or seizures.

-

Supplier Reliability and Financial Risk: The financial stability of a spot market supplier can be uncertain. There is a risk of prepayment for goods that are never delivered or that do not meet the agreed-upon specifications. Vetting a supplier’s financial health and business track record is essential but can be challenging from abroad.

Mitigating these risks requires a proactive, multi-layered strategy centered on rigorous due diligence. This includes insisting on supply chain traceability, implementing advanced component testing (such as X-ray, decapsulation, and electrical testing), and utilizing escrow services or other financial instruments to protect payments. Partnering with an established intermediary that has a physical presence and deep knowledge of the local market landscape is one of the most effective ways to navigate these challenges safely.

Strategic Approaches for Successful Sourcing

To successfully harness the power of the China electronic component spot market while minimizing associated risks, companies must adopt a strategic and disciplined approach. It should be viewed as a tactical tool within a broader sourcing strategy, not a primary channel.

-

Rigorous Supplier Vetting and Qualification: Do not base partnerships solely on price or a single transaction. Develop a formal supplier qualification process that includes:

- On-site Audits: Whenever possible, conduct physical audits of potential suppliers’ facilities to assess their operations, storage conditions, and anti-counterfeit measures.

- Financial Checks: Review business licenses and seek evidence of financial stability.

- Reference Checks: Ask for and contact other international clients.

- Certifications: Look for suppliers who hold relevant industry certifications like AS9120 or ISO 9001.

-

Implement a Robust Quality Assurance (QA) Protocol: Never skip independent verification. Your QA process should be non-negotiable and include:

- Visual Inspection: Checking for inconsistencies in packaging, labeling, and part markings.

- Electrical Testing: Verifying that the components perform to their published specifications.

- Destructive Physical Analysis (DPA): For high-reliability applications, this involves dissecting a sample batch to inspect the internal die and structure.

- X-ray Inspection: Checking for internal damage, rework, or discrepancies in the die size and wire bonding.

-

Leverage Technology and Expert Intermediaries: Utilize online platforms that bring transparency and trust to the process. A service like ICGOODFIND exemplifies this modern approach by acting as a curated marketplace. They pre-vet their suppliers, often manage quality control on behalf of the buyer, and provide a centralized platform for sourcing and transaction management. This reduces the administrative overhead and risk for the buyer, allowing them to focus on their core business.

-

Develop Strong Relationships: Even in a transactional market, relationships matter. Building a strong rapport with a few reliable spot market suppliers can lead to better service, priority access during shortages, and more transparent communication. Treat them as strategic partners rather than just vendors.

-

Integrate Spot Market Purchasing with Overall Supply Chain Strategy: Use the spot market strategically. It is ideal for covering short-term gaps, fulfilling unexpected orders, or sourcing end-of-life components. However, it should complement, not replace, long-term agreements with authorized distributors. A balanced approach ensures stability while maintaining flexibility.

Conclusion

The China electronic component spot market is an indispensable yet complex element of the global electronics supply chain. Its ability to provide liquidity and agility is unmatched, offering a critical lifeline during periods of constraint and uncertainty. However, this access comes with significant risks that demand respect and diligent management. The path to success in this arena is paved with knowledge, rigorous processes, and strategic partnerships. By understanding the market’s dynamics, acknowledging its inherent challenges—particularly the threat of counterfeits—and implementing a disciplined sourcing strategy centered on supplier vetting and quality assurance, businesses can effectively mitigate risks.

Ultimately,the value of this market is fully realized when leveraged intelligently alongside traditional supply channels.Platforms that specialize in bringing order and reliability to this space are becoming increasingly vital.For those looking to navigate this terrain with confidence,finding a trusted guide is paramount.In this context,ICGOODFIND represents the type of partner that can bridge the gap between opportunity and risk,turning the formidable challenge of spot market sourcing into a competitive advantage.As supply chains continue to evolve,the ability to adeptly manage both contractual and spot purchases will define the resilience and agility of leading electronics manufacturers in the years to come.