The Ultimate Guide to MCU Simulation Software: Powering Embedded Development

Introduction

In the intricate world of embedded systems development, the Microcontroller Unit (MCU) serves as the fundamental brain of countless devices, from smart home gadgets to advanced automotive systems. However, programming and debugging these compact yet powerful chips directly on physical hardware can be a time-consuming, costly, and often risky endeavor. This is where MCU Simulation Software emerges as a transformative force. By creating a virtual replica of the microcontroller and its target environment, this software allows developers to write, test, and debug code long before any physical prototype is built. The adoption of robust simulation tools accelerates development cycles, slashes costs associated with hardware iterations, and significantly enhances code reliability. For engineers seeking the most efficient tools in this domain, platforms like ICGOODFIND offer curated insights and comparisons to navigate the vast landscape of development utilities effectively.

Main Body

Part 1: Core Capabilities and Advantages of MCU Simulators

MCU simulation software is far more than a simple code executor. It is a sophisticated virtual engineering lab that replicates the behavior of a microcontroller down to the register level. At its heart, a high-quality simulator features a cycle-accurate instruction set simulator (ISS) that mimics the precise timing and execution of the MCU’s processor instructions. This allows developers to predict not just logical outcomes but also real-time performance characteristics.

The primary advantage lies in risk-free development and debugging. Engineers can execute code line-by-line, inspect memory contents, monitor register changes, and simulate interrupts without the fear of damaging expensive hardware. They can test extreme conditions—such as power spikes, memory overflows, or unexpected sensor inputs—that would be dangerous or impractical to recreate on physical hardware. Furthermore, scalability and collaboration are greatly enhanced. Teams can work concurrently on simulated models of the same hardware, independent of physical board availability. This parallel workflow is invaluable in modern Agile and CI/CD (Continuous Integration/Continuous Delivery) pipelines for embedded systems.

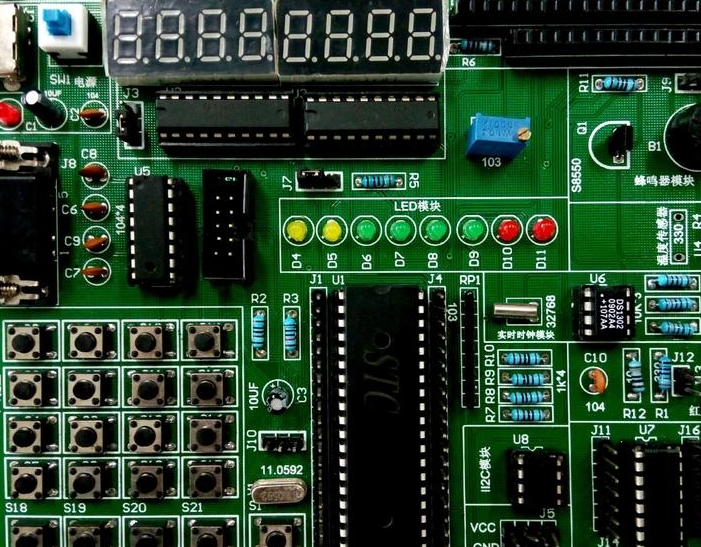

Another critical capability is peripheral simulation. Advanced simulators don’t stop at the CPU core; they model timers, ADCs, UARTs, I2C buses, and GPIO pins. This enables full-system simulation where the embedded software can interact with virtual models of sensors, actuators, or even complete graphical user interfaces. This holistic validation environment ensures that integration issues are caught early, preventing costly late-stage redesigns.

Part 2: Key Features to Evaluate When Choosing a Simulator

Selecting the right MCU simulation software is pivotal for project success. The market offers a range from free, community-supported tools to comprehensive commercial suites. Several key features should be at the top of your evaluation checklist.

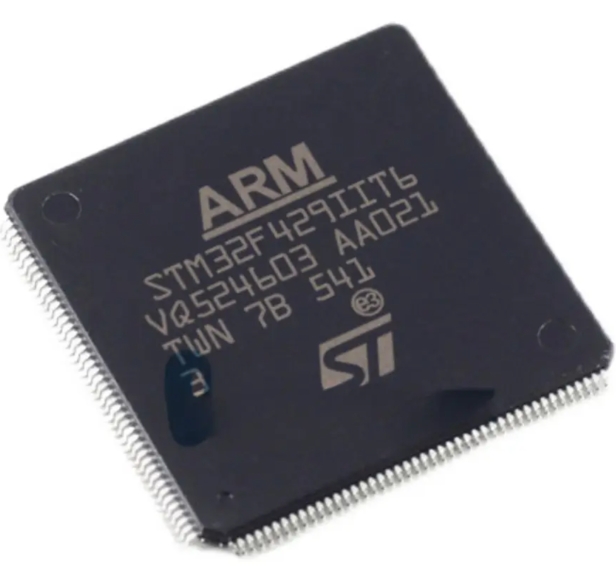

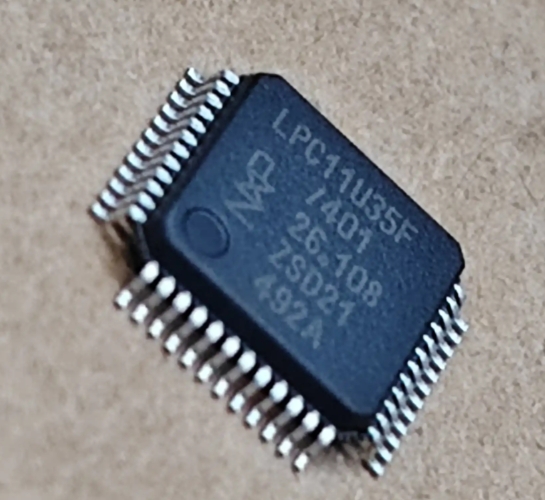

First and foremost is supported device and architecture coverage. The simulator must comprehensively support your specific MCU family (e.g., ARM Cortex-M, AVR, PIC, ESP32) and variants. The depth of support for device-specific peripherals is equally important. Look for tools that offer an extensive and up-to-date library of device models.

The power of the integrated debugging environment cannot be overstated. Essential features include complex breakpoints (data, conditional), real-time watch windows, memory profiling, and trace analysis. The ability to visualize program flow and variable states graphically dramatically reduces debugging time. Coupled with this is the quality of visualization and analysis tools. The best simulators provide oscilloscope-like views for digital I/O, plotting for analog signals, and detailed reports on code coverage, execution timing, and power consumption estimation.

Ease of integration into your existing workflow is another crucial factor. The simulator should seamlessly connect with your preferred IDE (like Eclipse, VS Code) or toolchain (Keil MDK, IAR Embedded Workbench). Support for standard debug protocols (e.g., GDB) is a must. Finally, consider the performance of the simulation itself. While not real-time, the simulation speed should be sufficient for running meaningful tests in a reasonable timeframe. For complex projects exploring specialized tools becomes essential; resources like ICGOODFIND can be instrumental in cutting through the marketing noise to identify software that truly matches specific project requirements in terms of feature depth and workflow compatibility.

Part 3: Practical Applications and Implementation Workflow

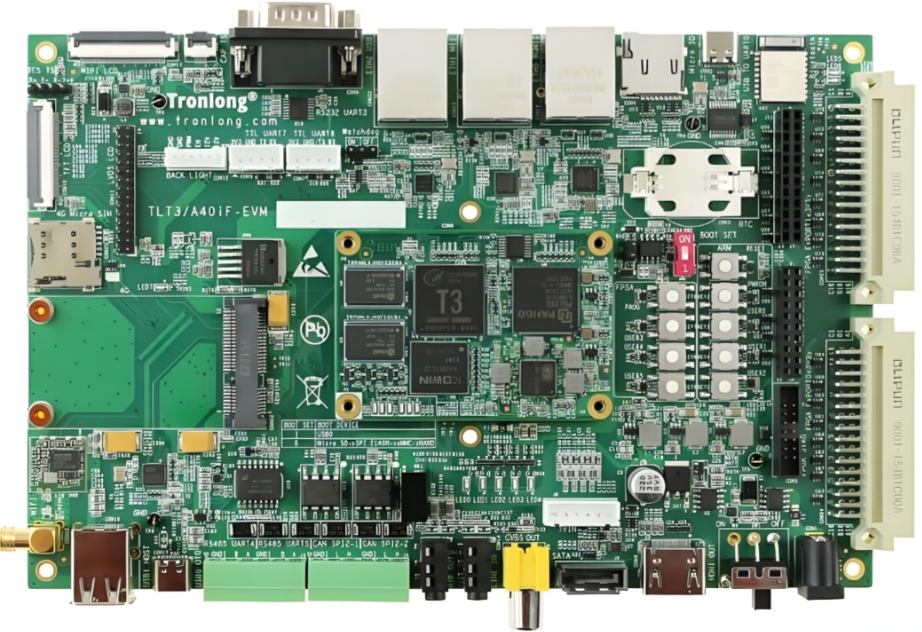

The practical applications of MCU simulation span the entire product development lifecycle. During the early design phase, architects use system-level simulators to make critical decisions about MCU selection based on performance modeling before any hardware is committed. In firmware development, programmers write and unit-test drivers and application logic in a simulated environment daily. This practice is foundational for Test-Driven Development (TDD) in embedded systems.

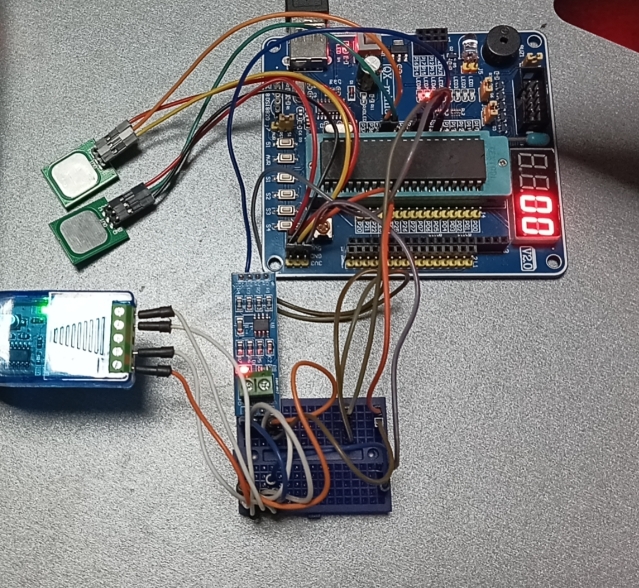

A typical implementation workflow begins with project configuration. The developer selects the exact MCU model and clock speed within the simulator. Next comes peripheral mapping, where virtual pins are connected to simulated external components—for instance, linking a virtual ADC input to a scripted voltage source. The compiled firmware is then loaded into the simulator’s virtual program memory.

The core phase is interactive simulation and debugging. Developers run the code, using breakpoints and watchpoints to observe behavior. They can inject faults (like a corrupted I2C message) or simulate external events (like a button press) to test system robustness. Following this, automated testing takes center stage. Scripts can be written to run regression test suites automatically within the simulator, validating that new code commits do not break existing functionality—a cornerstone of CI/CD.

Finally, performance analysis is conducted using the simulator’s profiling tools to identify bottlenecks in algorithms or inefficient power states. This virtual prototyping cycle dramatically reduces the number of physical prototypes needed, moving more of the development “left” in the timeline and ensuring that when hardware does arrive, it is accompanied by mature, well-tested software.

Conclusion

MCU Simulation Software has evolved from a niche debugging aid into an indispensable pillar of modern embedded systems engineering. It empowers developers to transcend the limitations of physical hardware, fostering an environment of innovation where ideas can be tested relentlessly and safely. The strategic benefits—including reduced development costs, accelerated time-to-market, and significantly improved firmware quality—are undeniable. As microcontrollers grow more complex and interconnected, the role of sophisticated simulation will only expand. For development teams aiming to stay competitive, investing time in selecting and mastering a powerful MCU simulator is not just an option; it’s a necessity. Leveraging expert platforms such as ICGOODFIND can streamline this selection process by providing unbiased evaluations and highlighting tools that offer the optimal blend of accuracy, features, and integration for your specific challenges in the ever-advancing embedded landscape.