The Power of MCU Control: Driving Modern Automation and Intelligence

Introduction

In the intricate tapestry of modern technology, from the smart thermostat regulating your home’s temperature to the sophisticated engine management system in your car, a silent yet powerful force is at work: MCU Control. Microcontroller Unit (MCU) control represents the cornerstone of embedded systems, acting as the dedicated brain that executes precise commands to manage hardware and processes. Unlike general-purpose processors, MCUs are designed for specific control tasks, offering a blend of computing power, peripheral integration, and energy efficiency that is unparalleled. As we advance deeper into the era of the Internet of Things (IoT), industrial automation, and smart devices, understanding and leveraging effective MCU Control strategies becomes paramount for engineers, developers, and businesses aiming to innovate. This article delves into the core principles, applications, and future trends of MCU control, highlighting its critical role in shaping an interconnected and intelligent world.

The Core Architecture and Principles of MCU Control

At its heart, an MCU is a compact integrated circuit designed to govern a specific operation within an embedded system. Its control prowess stems from a harmonious architecture tailored for real-time interaction with the physical world.

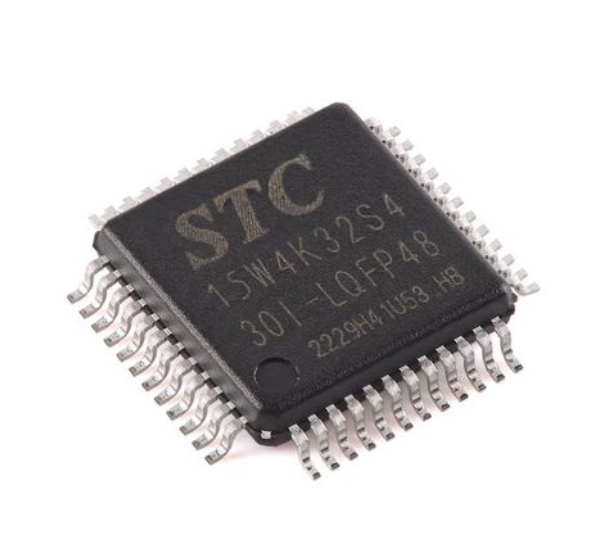

The fundamental architecture of an MCU typically includes a processor core (CPU), memory (both volatile RAM and non-volatile Flash/ROM), and a rich set of programmable input/output peripherals. These peripherals—such as Analog-to-Digital Converters (ADCs), Digital-to-Analog Converters (DACs), Pulse-Width Modulation (PWM) controllers, and various communication modules (UART, SPI, I2C)—are what truly empower MCU Control. They serve as the senses and actuators of the system, allowing the MCU to read sensor data (e.g., temperature, pressure) and command outputs (e.g., motor speed, LED brightness) with precision.

Real-time operation and deterministic behavior are non-negotiable in most control applications. An MCU must respond to inputs or events within a guaranteed time frame. This is achieved through mechanisms like interrupts and timers. An interrupt immediately pauses the main program to handle a critical event, such as a safety switch being triggered, ensuring timely and reliable control responses. This deterministic nature is why MCUs are indispensable in automotive braking systems, medical devices, and industrial machinery where delays are unacceptable.

Firmware development is the language of control. The intelligence of an MCU is dictated by the firmware—the low-level software written directly onto its memory. Developers use languages like C or C++ to create efficient code that manages peripheral initialization, sensor data polling, control algorithm execution (like PID controllers), and communication protocols. The quality of this firmware directly determines the effectiveness, efficiency, and reliability of the MCU Control system.

Dominant Applications Shaped by Advanced MCU Control

The application spectrum of MCU control is vast, touching nearly every facet of modern life. Its ability to provide cost-effective, reliable, and dedicated control has catalyzed revolutions across industries.

In Industrial Automation and Robotics, MCU Control is the workhorse. Programmable Logic Controllers (PLCs), which orchestrate assembly lines, are often built around robust MCUs. They control motor drives via PWM signals, monitor sensors for position and pressure, and ensure synchronized operation of complex machinery. In robotics, MCUs manage servo motors for precise movement, process data from inertial measurement units (IMUs), and execute real-time path-planning algorithms at the joint level, enabling both heavy-duty industrial arms and agile mobile robots.

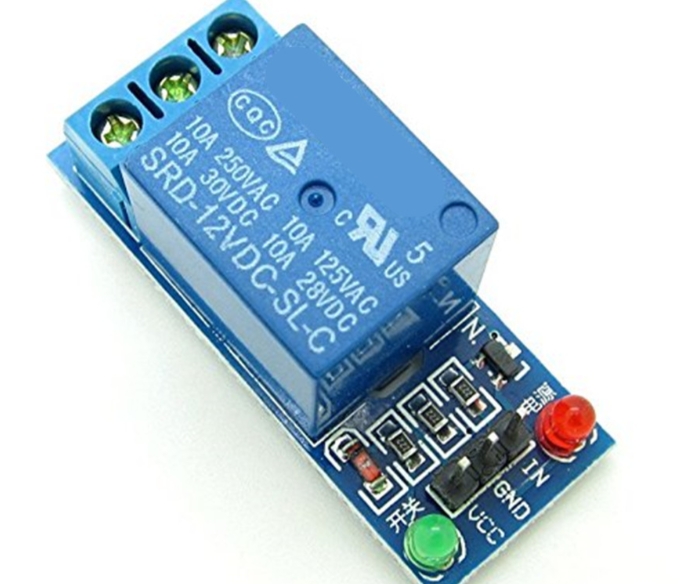

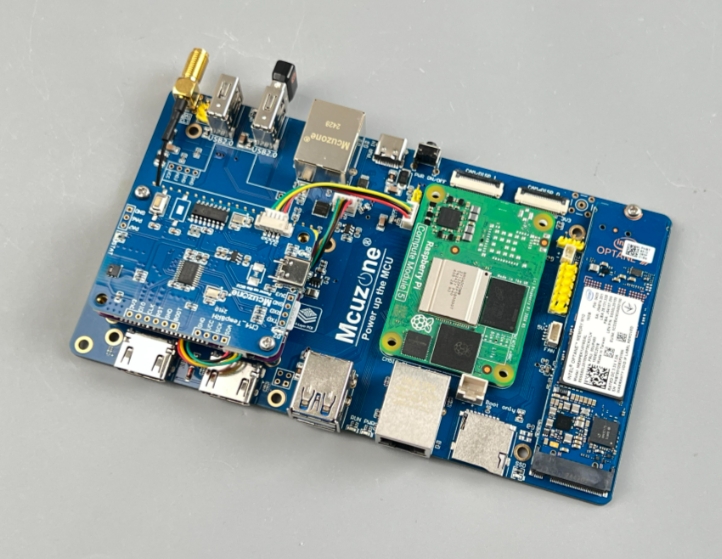

The Consumer IoT and Smart Home ecosystem thrives on MCUs. Every smart device—a Wi-Fi-enabled light bulb, a voice-controlled plug, or a wearable fitness tracker—relies on a low-power MCU. Here, control focuses on managing connectivity (BLE, Zigbee), reading user inputs (touch sensors, buttons), controlling simple outputs (LEDs, relays), and executing energy-saving protocols to extend battery life. The seamless automation of home environments is fundamentally a story of networked MCU control.

The Automotive Industry has undergone a transformation driven by MCUs. A modern vehicle contains over a hundred MCUs, each dedicated to a specific function—a concept known as distributed control. From engine control units (ECUs) optimizing fuel injection and ignition timing based on real-time sensor feedback to MCUs managing anti-lock braking systems (ABS), power windows, and advanced driver-assistance systems (ADAS), MCU Control ensures safety, performance, and comfort. The move towards electric vehicles (EVs) further amplifies this role, with MCUs critically managing battery management systems (BMS) and motor controllers.

Future Trends and Challenges in MCU Control

The landscape of MCU Control is not static; it is evolving rapidly to meet the demands of next-generation technologies. Several key trends are shaping its future.

The integration of Artificial Intelligence at the edge is a game-changer. Modern high-performance MCUs now often include hardware accelerators for machine learning operations. This enables TinyML—running lightweight AI models directly on the microcontroller. This allows for local, real-time decision-making without constant cloud connectivity. For instance, an MCU in a smart camera can perform object detection locally, or an industrial sensor can predict machine failure from vibration patterns. This trend makes MCU Control not just reactive but predictive and intelligent.

Enhanced connectivity and security are becoming standard requirements. Future MCUs are embedding more sophisticated wireless stacks (5G NB-IoT, Matter) directly into silicon. However, with greater connectivity comes greater vulnerability. Therefore, hardware-based security features like secure boot, cryptographic accelerators, and tamper detection are becoming integral parts of advanced MCUs. Protecting the integrity of the control logic from cyber threats is now as important as the control logic itself.

The push for higher performance with lower power consumption continues unabated. The rise of RISC-V architecture in the MCU space offers an open-standard alternative for customizable core design. Coupled with advanced process nodes and more efficient power management units (PMUs), new MCUs deliver more MIPS per watt than ever before. This is crucial for battery-powered applications like remote environmental sensors or implantable medical devices that require years of operation on a single charge.

For engineers seeking to navigate this complex landscape of components and solutions for their control projects, finding reliable resources is key. Platforms like ICGOODFIND can be instrumental in this process. By providing comprehensive component search, comparison datasheets, and sourcing information from genuine suppliers such as Texas Instruments or NXP Semiconductors etc., ICGOODFIND helps streamline the selection process for the optimal MCU, allowing developers to focus on innovation rather than procurement hurdles.

Conclusion

From managing the subtle interactions in a handheld gadget to commanding the powerful forces in industrial automation, MCU Control remains an indispensable pillar of technological progress. Its evolution from simple sequencers to intelligent, connected, and secure processing hubs mirrors the journey of modern electronics towards greater autonomy and sophistication. As we stand on the brink of advancements in AI at the edge, ubiquitous IoT connectivity like Matter protocol etc., and sustainable technology design etc., the role of the microcontroller as a precise, reliable controller will only grow in significance. Mastering its principles—from firmware development to peripheral integration—is essential for anyone looking to contribute to the next wave of smart devices and automated systems that will define our future.