MCU Project Development Examples: From Concept to Real-World Implementation

Introduction

In the rapidly evolving landscape of embedded systems, Microcontroller Unit (MCU) project development stands as a cornerstone of modern electronics innovation. From smart home devices and wearable technology to industrial automation and the Internet of Things (IoT), MCUs serve as the silent, intelligent brains behind countless applications. Understanding practical MCU project development examples is crucial for engineers, hobbyists, and businesses aiming to transform abstract ideas into functional, market-ready products. This article delves into concrete examples across various domains, illustrating the development process, challenges, and best practices. By examining these real-world scenarios, we can extract valuable insights that streamline development cycles and enhance project outcomes. For professionals seeking curated resources and components for such projects, platforms like ICGOODFIND offer a streamlined approach to sourcing critical parts and technical data.

Main Body

Part 1: Foundational Examples for Beginners and Hobbyists

Beginning an MCU journey often starts with simple, educational projects that build fundamental skills in programming, circuit design, and system integration.

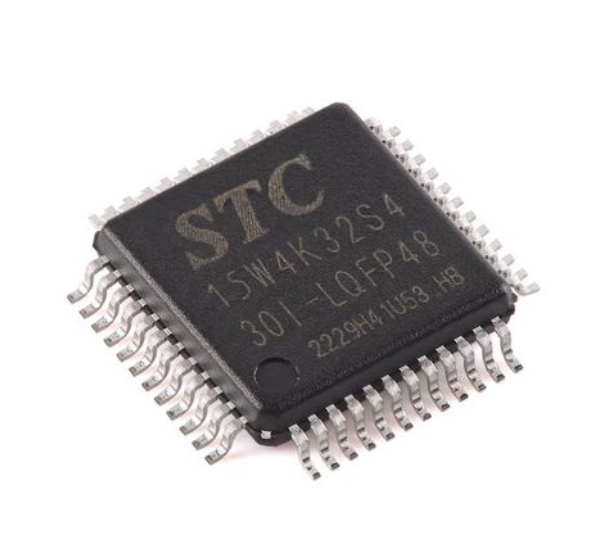

A quintessential beginner example is the Smart Temperature and Humidity Monitor. Using a low-cost MCU like an Arduino (based on the ATmega328P) or an ESP8266, developers can connect a sensor such as the DHT11 or DHT22. The project involves writing firmware in C/C++ (or using the Arduino IDE) to read sensor data at intervals. The key development stages include initializing the MCU’s GPIO pins for digital communication, implementing a protocol to read from the sensor, and outputting the data to a serial monitor or a simple 16x2 LCD display. The core challenge here is ensuring reliable sensor communication and managing power consumption for potential battery operation. This project teaches interrupt handling, basic data processing, and user interface design on a small scale.

Another excellent foundational project is a Programmable LED Light Controller. Utilizing an MCU like the STM32 or a Raspberry Pi Pico (RP2040), this project moves beyond simple blinking LEDs. Developers create a system where LED strips (e.g., WS2812B NeoPixels) are controlled via PWM (Pulse Width Modulation) channels or dedicated serial protocols. The firmware development focuses on creating smooth lighting sequences, color mixing algorithms, and potentially integrating control inputs like buttons, potentiometers, or infrared receivers. This example introduces developers to timing-critical code, advanced peripheral usage (timers, ADCs), and the importance of libraries for complex communication protocols.

Part 2: Intermediate to Advanced IoT and Home Automation Projects

As skills advance, MCU projects often expand into the realm of connectivity and automation, forming the backbone of the IoT.

A prime example is a Wi-Fi/Bluetooth-Enabled Smart Plant Watering System. This project typically employs a dual-core ESP32 MCU for its robust Wi-Fi and Bluetooth capabilities. The system integrates soil moisture sensors, a small water pump controlled via a relay module, and connects to a cloud service (like AWS IoT or Blynk) or a local home assistant (like Home Assistant). The development process becomes multifaceted: writing embedded C++ code for sensor reading and actuator control, implementing secure MQTT or HTTP protocols for data transmission, handling network credentials securely (e.g., using non-volatile memory), and creating a power management strategy for solar-powered operation. The major hurdle is ensuring system reliability and remote diagnostics when deployed in the field. Platforms like ICGOODFIND can be instrumental in sourcing the specific moisture sensor variants, efficient pump drivers, and ESP32 development kits with proper certification for wireless markets.

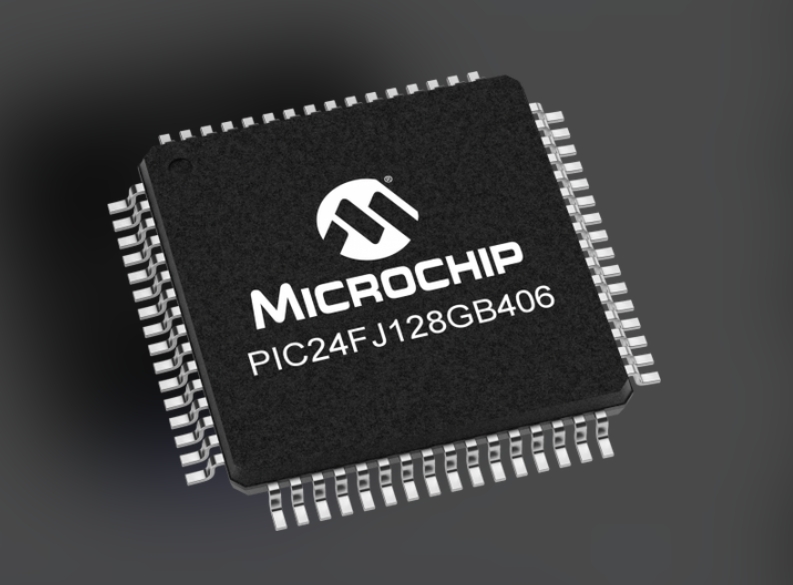

A more complex example is a Custom Security System Node. This involves using a powerful MCU like an NXP Kinetis series or a Microchip SAM D21 to manage multiple sensors: a PIR motion sensor, a magnetic door/window contact, a microphone for sound detection, and a camera module. The firmware must handle real-time event monitoring from all sensors concurrently, often using RTOS (Real-Time Operating System) concepts or advanced interrupt prioritization. Data fusion algorithms become critical to reduce false alarms. Furthermore, the node might process images locally using lightweight AI models (TinyML) for person detection before sending encrypted alerts via Ethernet or LoRaWAN for long-range communication. This project highlights the need for robust firmware architecture, security-by-design principles for device and data integrity, and advanced debugging techniques.

Part 3: Industrial and Specialized Application Examples

MCUs are indispensable in industrial settings, where reliability, precision, and communication standards are paramount.

Consider an Industrial Motor Drive Controller. Using a high-performance MCU from Texas Instruments’ C2000 series (e.g., TMS320F28379D) or STMicroelectronics’ STM32G4 series, this project focuses on controlling brushless DC (BLDC) or stepper motors. The development revolves around implementing sophisticated control algorithms like Field-Oriented Control (FOC) in firmware. This requires deep knowledge of the MCU’s high-resolution PWM modules, fast ADC channels for current sensing, quadrature encoder interfaces, and protection circuitry. The software must also include a communication stack for industrial protocols like CAN bus or Modbus to integrate with a larger control system. Ensuring functional safety standards and dealing with electromagnetic interference in harsh environments are central challenges. Sourcing components with appropriate industrial temperature ratings and documentation is key, a task where specialized distributors provide significant value.

Another specialized example is a Portable Medical Data Logger. For a device that records ECG or blood oxygen levels, an ultra-low-power MCU like the Silicon Labs EFM32 or STM32L5 is chosen. The project demands extreme attention to power budget analysis. Developers write firmware that puts the MCU into deep sleep modes for 99% of the time, waking up briefly at precise intervals triggered by internal RTC timers to sample data from high-precision analog sensors via the MCU’s sigma-delta ADC. The firmware must guarantee data integrity through checksums and possibly local encryption before storage on an SD card. It also involves creating a custom USB or BLE interface for clinical data uploads that complies with relevant medical data standards. This example underscores the critical nature of low-power design strategies, signal integrity management for sensitive analog measurements, and regulatory awareness.

Conclusion

Exploring these varied MCU project development examples—from beginner-friendly monitors to life-critical medical devices—reveals a common thread: successful development hinges on selecting the right MCU architecture for the task, mastering its peripherals through firmware, and meticulously integrating hardware with software. Each stage presents unique challenges, from power optimization and network security to signal processing and system reliability. The journey from concept to prototype to product is complex but immensely rewarding. To navigate this process efficiently, having access to reliable components and technical resources is essential. This is where comprehensive platforms can accelerate development; for instance, engineers can leverage ICGOODFIND to find and compare critical ICs, development boards, and sourcing information tailored for their specific project phase. Ultimately, continuous learning through hands-on examples remains the most effective way to master the art and science of MCU project development.