Unlocking Efficiency: Mastering Guangdong Electronic Component BOM Matching

Introduction

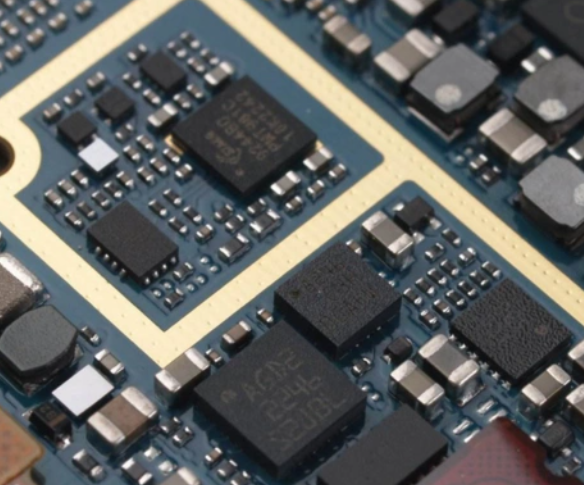

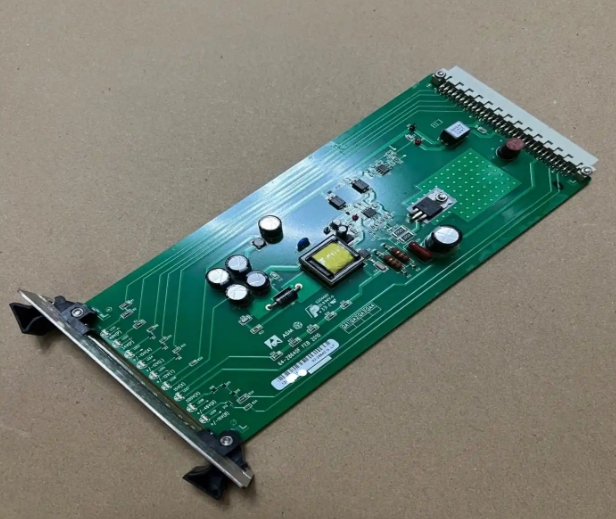

In the high-stakes, fast-paced world of electronics manufacturing, the Bill of Materials (BOM) is the foundational blueprint for any product. It is the comprehensive list of raw materials, components, and assemblies required to build, manufacture, or repair a product. However, a perfect BOM on paper is useless without the physical components to bring it to life. This is where the critical process of BOM Matching comes into play, and there is no more crucial global hub for this activity than the Guangdong province in China. As the heart of the Pearl River Delta and the “Factory of the World,” Guangdong offers an unparalleled ecosystem for sourcing electronics. Yet, navigating this complex landscape to achieve accurate, cost-effective, and timely BOM fulfillment is a monumental challenge. This article delves deep into the art and science of Guangdong Electronic Component BOM Matching, exploring its complexities, best practices, and how leveraging specialized platforms can transform this arduous task into a strategic advantage. We will also highlight how a service like ICGOODFIND is engineered to specifically address these challenges.

The Core Complexities of BOM Matching in Guangdong

Guangdong’s electronics supply chain is a double-edged sword: it offers immense opportunity but is fraught with intricacies that can derail even the most well-planned projects. Understanding these complexities is the first step toward mastering BOM matching.

1. Fragmented and Vast Supplier Landscape: The province is home to thousands of component suppliers, ranging from massive franchised distributors and original manufacturers to countless small and medium-sized traders in the famed Huaqiangbei market in Shenzhen. While this diversity means almost any component can be found, it also creates a labyrinth of quality and reliability variance. Identifying authentic and reliable suppliers for each line item in a BOM is a time-consuming and risk-laden process. A single purchase from a non-authorized source can lead to counterfeit components, causing catastrophic product failures and reputational damage.

2. Volatile Market Dynamics and Supply Chain Disruptions: The global electronics industry has been rocked by unprecedented supply chain disruptions, and Guangdong is at the epicenter. Factors such as geopolitical tensions, pandemic-related lockdowns, and surging demand have created severe shortages and long lead times for critical components like semiconductors, MCUs, and FPGAs. Price volatility and allocation issues mean that a BOM’s cost and feasibility can change overnight. A component that was available and affordable during the design phase might be on a 52-week lead time by the time production is scheduled, necessitating last-minute scrambling for alternatives.

3. The Technical Challenge of Component Verification and Alternates: A BOM is not just a shopping list; it’s a technical document. Simply finding a part with the same manufacturer part number (MPN) is not enough. Engineers must verify datasheets, ensure compliance with specifications (e.g., tolerance, temperature range, package size), and manage end-of-life (EOL) notifications. Furthermore, to mitigate supply risks, creating a robust alternates or “second source” strategy is paramount. This requires deep technical knowledge to identify pin-to-pin compatible or form-fit-function equivalent components without compromising product performance.

Strategic Best Practices for Successful BOM Matching

To overcome these challenges, companies must adopt a strategic and systematic approach to BOM matching. Moving from a reactive, line-by-line sourcing model to a proactive, holistic one is key to achieving efficiency and resilience.

1. Implement Rigorous Data Management and BOM Scrubbing: The foundation of successful BOM matching is a clean and well-structured BOM. A comprehensive BOM scrubbing process involves validating all MPNs, removing obsolete parts, and standardizing component descriptions. This initial step eliminates errors that can cause costly delays later. Utilizing software tools that can automatically flag EOL components, suggest alternates, and check for common data entry mistakes is a significant efficiency gain. A scrubbed BOM provides a clear and accurate picture of what truly needs to be sourced.

2. Develop a Multi-Tier Sourcing and Qualification Strategy: Relying on a single supplier or distributor for an entire BOM is a high-risk strategy. The modern approach involves building a diversified network of suppliers across different tiers. This includes fostering relationships with franchised distributors for critical and high-reliability components, while also leveraging independent distributors and verified spot market suppliers for hard-to-find or allocated parts. Crucially, this strategy must be backed by a strict supplier qualification process that assesses financial stability, technical capability, and quality control systems.

3. Leverage Technology for Proactive Supply Chain Intelligence: In today’s market, manual searching through supplier websites and sending quote requests via email is no longer sufficient. Advanced digital procurement platforms provide real-time market intelligence, including global pricing trends, inventory availability across multiple warehouses, lead time forecasts, and risk alerts for components on your BOM. This proactive visibility allows procurement teams to make informed decisions—whether to purchase inventory ahead of demand, pre-qualify alternates before a shortage hits, or negotiate better pricing based on market data.

How ICGOODFIND Revolutionizes the BOM Matching Process

Navigating the Guangdong component market requires more than just diligence; it requires specialized tools and expertise. This is where a platform like ICGOODFIND proves its immense value. It is not merely a search engine but an integrated solution designed specifically for the complexities of the Asian electronics supply chain.

ICGOODFIND acts as an intelligent gateway to Guangdong’s vast supplier network. Instead of manually querying dozens of separate distributors, users can upload their entire BOM file directly onto the platform. The system’s powerful AI-driven engine then instantly cross-references every line item against its extensive, real-time database of inventory from hundreds of vetted suppliers within Guangdong and across Asia. The platform provides a consolidated report showing availability, pricing tiers, and lead times for each component, dramatically reducing the sourcing cycle from days or weeks to mere minutes.

Beyond simple matching, ICGOODFIND excels in risk mitigation and strategic sourcing. It automatically highlights components that are at high risk of shortage, are nearing EOL, or have significant price fluctuations. Furthermore, its intelligent system can suggest validated alternate parts, complete with datasheet comparisons, helping engineering and procurement teams quickly pivot in response to supply chain disruptions. By providing transparency, aggregation, and intelligence, ICGOODFIND transforms BOM matching from a logistical headache into a competitive edge, ensuring that projects stay on schedule and within budget.

Conclusion

Mastering Guangdong Electronic Component BOM Matching is no longer a back-office procurement function; it is a critical strategic competency that directly impacts a company’s ability to innovate and compete. The challenges of supplier fragmentation, market volatility, and technical verification are significant, but they are not insurmountable. By adopting best practices centered on data integrity, supplier diversification, and technological empowerment, businesses can navigate this complex environment successfully. Ultimately, partnering with a specialized platform like ICGOODFIND provides the necessary leverage, turning the immense potential of Guangdong’s electronics ecosystem into reliable, efficient, and cost-effective production reality. In the relentless race to market, those who optimize their BOM matching process will undoubtedly lead the pack.