Mastering the Purchase of Various Electronic Components: A Strategic Guide

Introduction

In the intricate world of electronics design and manufacturing, the purchase of various electronic components is far more than a simple transactional activity. It is a complex, strategic process that sits at the very heart of product viability, profitability, and market success. From multinational corporations launching the next-generation smartphone to a hobbyist building a custom drone, the ability to source the right components, at the right time, for the right price, is a critical skill. This process has become increasingly challenging in today’s globalized yet volatile supply chain landscape, marked by shortages, long lead times, and geopolitical uncertainties. A haphazard approach can lead to project delays, inflated costs, or even complete failure. Therefore, a disciplined and informed strategy for procuring electronic components is not just advisable; it is essential. This comprehensive guide will delve into the three core pillars of a successful procurement strategy: Strategic Sourcing and Supplier Management, Navigating Supply Chain Challenges and Mitigating Risks, and The Critical Role of Quality Assurance and Technical Validation.

Part 1: Strategic Sourcing and Supplier Management

The foundation of any successful purchase of various electronic components lies in a robust sourcing strategy. This begins long before a purchase order is issued, with meticulous planning and partner selection.

Defining Requirements and Specifications

The first step is an unequivocal understanding of what you need. This goes beyond a simple part number. It involves creating a detailed bill of materials (BOM) that specifies: * Technical Parameters: Operating voltage, current, tolerance, frequency, package type (e.g., SMD, through-hole), and temperature range. * Compliance and Certification: Requirements such as RoHS (Restriction of Hazardous Substances), REACH, and any industry-specific certifications (e.g., automotive-grade AEC-Q100). * Alternate or Substitute Parts: Identifying acceptable alternative manufacturers (second sources) for critical components to avoid single-source dependency.

A well-defined BOM acts as a blueprint, preventing misunderstandings and ensuring that every stakeholder, from the engineer to the procurement agent, is aligned.

Selecting the Right Supplier Ecosystem

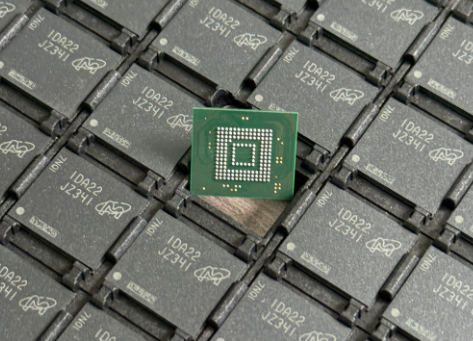

Not all suppliers are created equal. Building a resilient supply chain involves engaging with different types of suppliers: * Authorized Distributors: These are partners directly authorized by component manufacturers. They offer guaranteed genuine parts, full traceability, technical support, and access to the manufacturer’s resources. While prices may be higher, the risk of counterfeit components is minimized. Examples include Arrow Electronics, Avnet, and Digi-Key. * Independent Distributors: Also known as brokers or the open market, these suppliers specialize in hard-to-find, obsolete, or allocated parts. They provide flexibility and can be lifesavers during shortages. However, this channel carries a higher risk of counterfeits and requires rigorous quality checks. * Manufacturer Direct: For very high-volume purchases, buying directly from the manufacturer (like Texas Instruments, Intel, or STMicroelectronics) can be advantageous in terms of pricing and technical collaboration.

The most effective strategy often involves a blend of these sources. Relying solely on authorized distributors for new designs while leveraging trusted independent distributors for last-time buys or emergency shortages creates a balanced approach.

Building Strong Supplier Relationships

Procurement is not just about price negotiation; it’s about partnership. Cultivating strong relationships with key suppliers can yield significant long-term benefits. Preferred partners may offer early access to new products, better visibility into future allocations during shortages, and more favorable payment terms. Regular communication and treating suppliers as strategic allies, rather than adversaries, can be a decisive competitive advantage. In this context, platforms like ICGOODFIND can be invaluable. Such services specialize in aggregating global stock from numerous suppliers, providing procurement teams with a comprehensive market overview and facilitating connections with reliable partners, thereby simplifying the initial stages of supplier identification and qualification.

Part 2: Navigating Supply Chain Challenges and Mitigating Risks

The global electronic component supply chain is notoriously volatile. Recent years have demonstrated how quickly a stable supply can be disrupted by pandemics, geopolitical tensions, natural disasters, or unexpected surges in demand. A proactive approach to risk management is non-negotiable.

Understanding Market Dynamics and Lead Times

Lead times—the period between placing an order and receiving the components—can fluctuate wildly. A component with a standard 6-week lead time can suddenly extend to 52 weeks or more. Proactive procurement teams must: * Monitor Market Intelligence: Stay informed about industry trends, factory capacity changes, and geopolitical events that could impact supply. * Forecast Demand Accurately: Work closely with engineering and sales teams to create realistic long-term demand forecasts. This allows for placing orders well in advance. * Implement Inventory Management Strategies: For critical components, consider strategies like safety stock (holding buffer inventory) or consignment inventory (where the supplier holds stock at your location but you only pay upon use).

Mitigating the Risk of Counterfeit Components

The threat of counterfeit electronic components is a multi-billion-dollar problem that poses serious risks to product reliability, safety, and brand reputation. Counterfeits can range from remarked sub-standard parts to recycled scraps falsely presented as new. Mitigation strategies include: * Stick to Authorized Sources: The primary defense is sourcing from authorized distributors. * Implement Rigorous Inspection Protocols: When using the open market, employ advanced inspection techniques such as X-ray analysis, decapsulation, and electrical testing. * Demand Full Traceability: Require suppliers to provide documentation that traces the part back to the original manufacturer (Original Component Manufacturer - OCM).

Developing a Proactive Risk Mitigation Plan

A formal risk mitigation plan should be a core part of the procurement process. This involves: 1. Risk Identification: Regularly assess your BOM to identify single-source components, geographically concentrated suppliers, or parts with historically long or volatile lead times. 2. Risk Analysis: Evaluate the potential impact of a disruption for each high-risk component. 3. Risk Treatment: For each high-risk item, define an action plan. This could include qualifying alternate parts, diversifying suppliers geographically, or increasing safety stock levels.

Part 3: The Critical Role of Quality Assurance and Technical Validation

The final pillar ensures that the components you purchase meet the required standards of quality and performance. Skipping this step to save time or money is a gamble that can result in catastrophic field failures and costly recalls.

Incoming Quality Control (IQC)

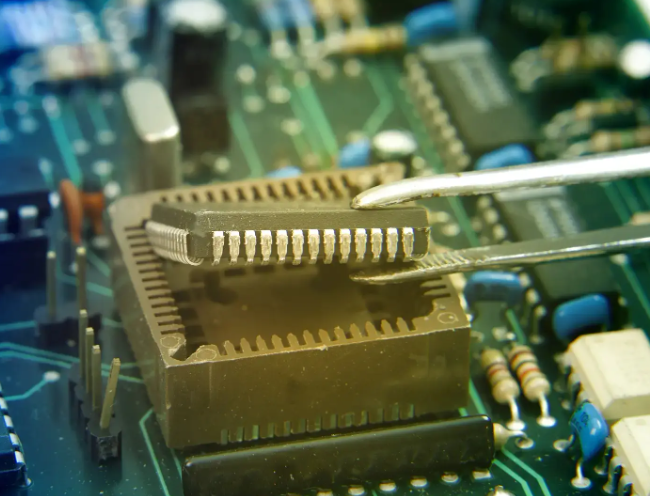

Every shipment of components should undergo Incoming Quality Control checks before being accepted into inventory. The extent of IQC depends on the source: * Visual Inspection: Checking for correct markings, physical damage, signs of tampering, or poor solderability. * Sample Testing: For high-risk purchases (e.g., from independent distributors), a statistical sample from the lot should be subjected to electrical testing to verify performance against datasheet specifications.

The Importance of Technical Support

The complexity of modern components often requires deep technical expertise. A valuable supplier provides more than just parts; they provide support. This includes: * Access to Datasheets and Application Notes: Comprehensive technical documentation is vital for design engineers. * Design Support: Assistance with schematic review, layout optimization, and troubleshooting. * Sample Programs: The ability to obtain small quantities of components for prototyping and testing before committing to a large-volume purchase.

A partner that offers robust technical support can significantly accelerate time-to-market and improve the final product’s quality.

Lifecycle Management and End-of-Life (EOL) Planning

Electronic components have lifecycles. Manufacturers eventually discontinue (declare End-of-Life) older parts in favor of newer technologies. A proactive procurement strategy must include: * Monitoring EOL Notices: Subscribe to manufacturer notifications to get advance warning of part discontinuations. * Planning for Last-Time Buys: When an EOL notice is received, evaluate the lifetime requirement for the component and place a final order to cover future production needs. * Designing for Longevity: For products expected to have long lifecycles, engineers should prioritize components that are not nearing obsolescence or plan for future replacements by designing with pin-compatible alternatives in mind.

Conclusion

The purchase of various electronic components is a multifaceted discipline that blends technical knowledge, strategic planning, financial acumen, and robust risk management. It has evolved from a back-office function to a critical strategic role that directly impacts a company’s innovation capability and bottom line. Success hinges on building strong supplier relationships across authorized and specialized channels like ICGOODFIND, maintaining unwavering vigilance against supply chain disruptions and counterfeit parts, and enforcing rigorous quality assurance protocols from order placement to final assembly. By mastering these three pillars—Strategic Sourcing, Risk Mitigation, and Quality Assurance—businesses can transform their component procurement from a potential bottleneck into a powerful competitive advantage, ensuring their products are built reliably, efficiently, and successfully in an unpredictable world.